The Application Of Phosphoric Acid In Vegetable Oil Refining Machine

- Usage: Cooking Oil

- Type: Cooking Oil Refinery Machine, Cooking oil machines

- Automatic Grade: Semi-Automatic

- Production Capacity: 100%

- Voltage: 220V/380V

- Power(W): 7.5kw

- Dimension(L*W*H): Based on Oil Press Machine capacity

- Weight: 1200kg

- Product name: small scale unrefined Cooking oil making line price

- Raw Material: Sunflower Oil, Sesame Oil, Soybean Oil, Palm Oil, Coconut Oil,Peanut Oil, Castor Oil, etc

- Advantage: Simple Operation

- Warranty: 12 Months

- Item: Edible Oil Press

- Character: Screw Oil Pressing Machines

- Use for: Oil Yield

- Section: Pretreatment

- Product: National Oil Standard

1. In batch type vegetable oil refining plant: The acid degumming process generally proceed with alkali deacidification process together. After adding phosphoric acid, stir the oil for about 30 min, and then add alkali liquid to proceed the neutralization reaction.

small rice bran oil refinery system in lagos Machine Type: rice bran oil refinery system; Production Capacity: 50 Sets/ Month; Dimension(L*W*H): 22*10*8cm; Voltage: adjustable; Certification: CE, ISO, ISO9001,SGS,TUV and Others; Bleaching earth consumption: 3-5 Kg / T; Raw Material: rice bran; Market: lagos

Alta. Biofuel Refinery On Track The Western Producer

- Usage: Cooking oil refining machine

- Type: Cooking oil refining machine

- Production Capacity: 100%

- Voltage: 220/380V, as the customer local voltage

- Power(W): according to the capacity

- Dimension(L*W*H): according to the capacity

- Weight: 30tons

- Raw Material: Sunflower Oil, Sesame Oil, Soybean Oil, Palm Oil, Coconut Oil,Peanut Oil, Castor Oil, etc

- Warranty: 12 Months

- Color: as customers requirement

- Application: Oil Production Line

- Turn key service: yes

- Advantage: High Oilput

- Character: Oil Processing Line

- Brand: Dinter

- Machinery type: Complete Line

Imperial Oil’s biofuel refinery planned for Alberta’s Strathcona County will use Canadian-grown canola oil as a feedstock produced from 2.5 million tonnes of canola seed annually. File photo

crude peanut oil refinery system manufacturing in bangladesh Machine Type: peanut oil refinery system; Production Capacity: 11kg/batch; Dimension(L*W*H): 2200*810*1850mm; Power: 0.37-7.5KW; Ambient temperature: -10℃~50℃ Core Components: Motor, Pressure vessel, Pump, Gearbox, mustard oil making machine

Small Tea Seed Oil Refinery System In Botswana

- Usage: vegetable oil

- Type: refining, refining process

- Production Capacity: 100%

- Voltage: 400/380/220V

- Power(W): 50KW

- Dimension(L*W*H): 17*12*10meter

- Weight: 25600kg

- Power: Electricity/water/steam

- Raw Material: Sunflower Oil, Sesame Oil, Soybean Oil, Palm Oil, Coconut Oil,Peanut Oil, Castor Oil, etc

- Capacity: 1-600TPD

- Certifate: ISO&BV&CE

- Operating: Easy operate

- Brand: Yongle

- Made in: China

- Color: According to customers

small tea seed oil refinery system in botswana Machine Type: tea seed oil refinery system; Production Capacity: 1-360TPD; Dimension(L*W*H): 1950*742*1500; Power: 67.5kw; Color: White full power pig bone/beef bone/poultry bone crusher machine; Oil Speed(kg/h): 2-3kg; Raw Material: tea seed; Market: botswana

oil refinery system with ceiso in johannesburg. Machine Type: vegetable seed oil refinery system; Production Capacity: oil centrifuge; Dimension (L)*(W)*(H): 520*520*1600mm; Voltage: 220~415 V; Display: Color LCD with Touch Screen; Filter Cake Thickness:20mm,25mm,30mm,35mm,40mm; Raw Material: vegetable seed; Market: johannesburg

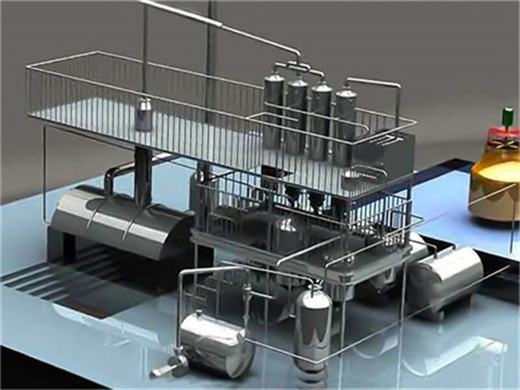

Small Oil Refinery

- Usage: crude Cooking oil refinery machine

- Type: Cooking Oil Refinery Machine

- Production Capacity: 30T~100T/D

- Voltage: 220V/380V

- Power(W): 28KWh/T

- Dimension(L*W*H): according to capacity

- Material: stainless steel and carton steel

- Steam consumption: <280KG/T (0.8MPa)

- Business type: manufacturer

- Crude oil moisture and volatile matter: <0.3%

- Item: crude Cooking oil refinery machine

- Raw Material: Sunflower Oil, Sesame Oil, Soybean Oil, Palm Oil, Coconut Oil,Peanut Oil, Castor Oil, etc

- Dimension: depending on capacity

The Small Oil Refinery is classified under our comprehensive Grain Processing Machinery range.Opting for wholesale offers benefits like cost savings due to bulk orders, consistent supply for uninterrupted production schedules, and the potential for customization to match specific processing requirements.

Flax Seed Oil Refinery System In Afghanistan

- Usage: All kinds of edible oil

- Type: Cooking Oil Refinery Machine

- Production Capacity: 100%

- Voltage: 380V OR REQUESTED

- Power(W): 300KW

- Dimension(L*W*H): 14X8X9M WORKSHOP

- Weight: 10T

- material: stainless steel or others

- Capacity: accordding to your requirement

- outstanding: low price, fast return

- Distillation range: 68-75℃

- Installation time: 30-45 days

- Delivery Time: 30 days

- Delivery port: Qingdao port

- Project: Turn key project

- Item: unrefined Cooking oil plant

Machine Type: flaxseed oil refinery system, Production Capacity: 50T~150T/D, Dimension(L*W*H): 2300*820*1370mm, Total Power: 2×0.25 kW, Certificate: ISO9001:2015

- What is the process of refining canola oil?

- Canola oil refining is the process to remove undesirable substances like phospholipids, free fatty acids, sterols, waxes, oxidation products, water, aromatic compounds, and pigments from crude canola oil, which adversely affect the quality and durability of the oil.

- How is canola oil extracted?

- Canola oil is extracted using two main methods: Mechanical Press and Solvent Extraction. In the Mechanical Press method, Canola oilseeds are pressed in a series of Screw Presses / Expellers. This process does not use chemicals and leaves approximately 5-7% oil in the residual Cake/Meal.

- How is canola oil filtered?

- Canola oil is filtered through a two-step process. First, the extracted oil is transferred to a Vibro Separator or Screening Tank for preliminary separation of suspended solids, known as 'foots'. Then, the pre-cleaned oil undergoes final filtration in a filter press or vertical pressure leaf filter to obtain filtered canola oil.

- Which countries produce canola oil seeds?

- The major producers of canola oil seeds are the European Union, Canada, China, and India. The European Union and Canada are among the leading producers, and the Canola (and Rapeseed) oil is the 3rd leading source of vegetable oil, after soybean and palm oil.

- What is the process for canola seed processing?

- To process canola seeds, we need basic equipment including a Seed Cleaner, Seed Cooker/Kettle, Oil Press, Filter Press, Steam Boiler, Screw Conveyors, and Bucket Elevators. The process begins with seed cleaning, where canola seeds are separated and cleaned to remove impurities such as dust, metal, and plant stalks.

- What is canola oil and rapeseed oil?

- Canola (and rapeseed) oil is the third leading source of vegetable oil, after soybean and palm oil. Canola and rapeseed oil are the same thing, with canola being a variety of rapeseed that has lower erucic acid content and lower glucosinolates. The global production volume of Rapeseed oil has risen steadily over the last several years, and there are still investors who want to enter the Canola Oil Manufacturing industry.