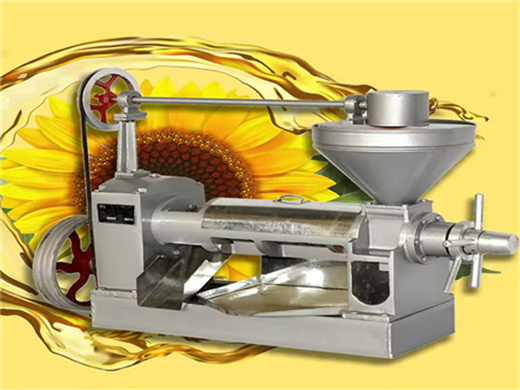

Crude Sunflower Edible Oil Refinery Plant

- Usage: edible oil

- Type: Cooking Oil Refinery Machine

- Production Capacity: 98%

- Voltage: 220V/380V/440V

- Power(W): 11KW

- Dimension(L*W*H): 1.5*2.6*3.6M

- Weight: 0.5-10T

- Product name: refined Cooking cooking oil machine

- Raw Material: Sunflower Oil, Sesame Oil, Soybean Oil, Palm Oil, Coconut Oil,Peanut Oil, Castor Oil, etc

- Application: all kinds of oil seeds

- Function: get grade 1 cooking oil

- Warranty: 365 days

- Feature: Multifunction High Efficient

- Model: QIE88

- Quality: 15 years service time

- Advantage: 35 years experience

- Color: Nippon

After pressing, the sunflower oil needs to be further processed to become edible oil, which called refining. Refining is the process of removing impurities and harmful components from the crude cooking oil according to the condition of the crude cooking oil to turn the crude cooking oil into standard edible oil.

Customers sometimes express the desire to produce multiple types of cooking oil using a single machine. In response, it should be noted that high oil-content raw materials typically undergo pretreatment, pre-pressing, and solvent extraction methods, whereas low oil-content raw materials are directly used in the refining method after the pretreatment.

Sunflower Oil Refining Process Essentials For Optimal Effects

- Usage: degumming machine for soy oil

- Type: degumming machine for soy oil

- Production Capacity: 150T~300T/D

- Voltage: 220V/380V

- Power(W): according to the capacity

- Dimension(L*W*H): depending on the capacity

- Weight: according to the capacity

- Overseas installation: Yes

- Business type: manufacturer

- Item: degumming machine for soy oil

- Moisture and volatile matter: <0.2%

- Features: high quality machine

- Technical service: Yes

- After sale service: Yes

- Brand: LD'e

Start Profitable Sunflower Oil Refining Plant Supported by Professional Techniques. This article focuses on the proven sunflower oil refinery process, providing relatively accurate process parameters, effectively improving the efficiency of sunflower oil refining, reducing oil refining losses and lowering production costs.

- Fully equipped 200 TPD Edible Oil Refinery setup, inclusive of a boiler. Utilizing 1,500 MT capacity storage tanks with a total of 4 tanks. Efficient godown facility with a dedicated packing line. Running a 25 TPD acid oil plant alongside an advanced Effluent Treatment Plant.

Edible Oil Refinery, Vegetable Oil Refinery, Cooking Oil Processing Machine

- Type: neem oil extraction machine

- Use: neem oil extraction machine

- Product type: neem oil extraction machine

- Usage: high grade oil

- Voltage: 220/380 OR other

- Residual oil in meal: ≤ 1%

- Production Capacity: 20-2000TPD

- Steam consumption: ≤ 280KG/T (0.8MPa)

- Power consumption: ≤ 15KWh/T

- Raw Material: Sunflower Oil, Sesame Oil, Soybean Oil, Palm Oil, Coconut Oil,Peanut Oil, Castor Oil, etc

- Material: Stainless Steel and carbon steel

- Price: Negotiation

Edible Oil Refinery consists of Soyabean Oil Refinery Plant, Coconut Oil Refinery Plant and Sunflower Oil Refinery Plant. We also manufacture Small Scale Mini Oil Refinery and Batch Type Oil Refinery Plants from India.

A plethora of health benefits has placed Sunflower oil on millions of tables as one of the most favored cooking medium in India and abroad and across the world. Learn More groundnutoilrefinery

Sunflower Oil Refinery Plant

- Usage: Oil Refining

- Type: Oil Refining

- Production Capacity: 100%

- Voltage: 220V/380V/440V

- Power(W): 10-50kw

- Dimension(L*W*H): According to the capacity

- Weight: According to the capacity

- Item: Dinter Durable In Use Crude Linseed Oil Refining Equipment

- Voltatile substance in crude oil: ≤0.3%

- Clay consumption: depending on color of crude oil

- Solvent contain in crude oil: ≤200ppm

- Oil residue in waste clay: ≤25% of waste clay

- Performance: Excellent

- Steam pressure: ≥1.2MPa

- Steam consumption in refining: ≤280kg/ton

- Warranty: 12 Months, long term technical support

- Feature: High Output

We design and develop complete integrated refinery plant and system specially for sunflower oil. Sunflower oil is considered to be one of the most stable oils for frying. The demand for oils with a lower degree of unsaturation than those of traditional oils has significantly increased the availability of oils of high thermostability.

What Are Sunflower Oil Refining Process Techniques?

- Usage: All kinds of edible oil

- Type: Cooking Oil Refinery Machine

- Production Capacity: 100%

- Voltage: 380V OR REQUESTED

- Power(W): 300KW

- Dimension(L*W*H): 14X8X9M WORKSHOP

- Weight: 10T

- material: stainless steel or others

- Capacity: accordding to your requirement

- outstanding: low price, fast return

- Distillation range: 68-75℃

- Installation time: 30-45 days

- Delivery Time: 30 days

- Delivery port: Qingdao port

- Project: Turn key project

- Item: Cooking oil refining mill

The rational design of the refining process is crucial for the development and competitiveness of investing sunflower oil refining process plant. It can eliminate bottlenecks and waste in the production process, enhance refining quality and production efficiency, reduce costs, thereby increasing output and profits.

- How to make sunflower oil edible?

- The extracted sunflower oil should be processed further to make it an edible product. Edible oils are refined to improve their flavor, odor, color and stability. The refining process will remove contaminants such as phosphatides, free fatty acids and pro-oxidants. Apart from the normal refining steps, some oils and fats need further processing.

- What are the different types of edible oil in Indonesia?

- The primary types of edible oil consumed in Indonesia include palm oil, coconut oil, soybean oil, and sunflower oil. Executive Summary The Indonesia Edible Oil Market has witnessed robust growth over the past few years.

- How to get idea about our sunflower oil refinery?

- Idea about our Sunflower Oil Refinery can be obtained by going through the below pictures. Our Batch Type Sunflower Oil Refinery Plant will give High-Quality Refined Sunflower Oil as Output. Neutralization Reactor: For acid refining, alkali refining and water washing. Decolorization Reactor: To Bleach the Oil and remove pigment from oil.

- What will drive the Indonesia edible oil market in 2025-2033?

- In the coming years, continuous upgradations in cold-pressing and refining technologies for enhanced oil production will continue to drive the market for edible oils in Indonesia. IMARC Group provides an analysis of the key trends in each sub-segment of the Indonesia edible oil market report, along with forecasts for the period 2025-2033.

- What is sunflower oil refinery plant?

- Sunflower Oil Refinery Plant is a machinery setup manufactured and developed to refine the crude sunflower oil with the key step of elimination of impurities from that crude oil. We at Tinytech Udyog offer small scale to medium scale Sunflower Oil Refinery Plants on Turnkey basis.

- Why is edible oil so popular in Indonesia?

- Growing population and changing dietary habits are driving the demand for edible oil in Indonesia. Palm oil is the most widely consumed edible oil in the country, owing to its affordability and versatility.