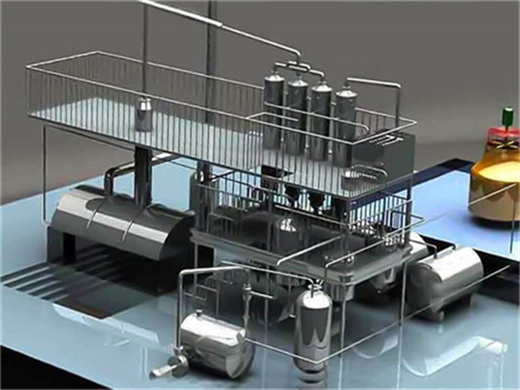

Major Palm Oil Refiners Equipment

- Usage: Cooking Oil

- Type: Cooking Oil Refinery Machine

- Production Capacity: 5-2000T/D

- Voltage: 380V/220V

- Power(W): Up to specification

- Dimension(L*W*H): Up to Cooking oil production capacity

- Weight: Up to Cooking oil refinery capacity

- color: green or red

- material: carbon steel or stainless steel

- package: nude or according to customers' require

- delivery date: within 35 days after customer confirm the order

- Raw Material: Sunflower Oil, Sesame Oil, Soybean Oil, Palm Oil, Coconut Oil,Peanut Oil, Castor Oil, etc

- Product name: crude Cooking oil refinery equipment

No Company Name Company Full Address City-Town State Factory Address(es) City-Town State Website; 1: AGRI ASIA REFINERY SDN. BHD. No. 60, Jalan Bunga Melati 2/2, Section 2, 40000 Shah Alam, Selangor, Malaysia.

Processing of Refined Palm Oil or Kernel Oil: To get high grade oil products, the crude palm oil can be further processed in palm oil refinery equipment. The small scale palm oil refining plant makes an appealing business venture for investors and the like looking into creating palm oil processing business.

Thailand Palm Oil Press Machine Palm Oil Mill Plant In Bolivia

- Usage: Cooking Oil machine

- Type: Cooking oil machine

- Production Capacity: 10T-3000TPD

- Voltage: 220V/380V

- Power(W): According to your Capacity

- Dimension(L*W*H): According to your Capacity

- Weight: depend on the mode of Cooking oil machine

- Item: Cooking oil machine

- Process: pretreatment,extraction,refining

- Electric Consumption: 28Kwh/T Oil

- Soften Water: 150Kg/T Oil

- Phosphoric Acid: 2~3 kg/T Oil

- Bleaching Earth Consumption: Bleaching Earth Consumption

- Refining Rate: Refining Consumption 1%

- Steel: Stainless steel

- Supplier Type: Manufacturer

Palm Oil Refining Machine. For example, if your palm fruit processing capacity is about 1-5 tons/hour, you can choose the standard configuration of palm oil production line equipment, mainly by the fermentation tank, fruit extractor, mashing tank, palm oil press, rotary sieve and plate and frame filter and other equipment, the investment is generally from hundreds of thousands to millions.

'TINYTECH PLANTS', established in the year 1983, is the pioneer in oil mill machinery, palm oil mill machinery, refinery plants not only in indonesia but we have large customer base all over the world in 119 countries. 'TINYTECH PLANTS' began by manufacturing Mini oil mills to produce oil from any kind of oil seeds.

Small Scale Oil Refinery Plant Palm Oil Plant

- Type: crude Cooking oil refinery machine

- Use: crude Cooking oil refinery machine

- Color: Yellow

- description: Continuous automatic oil refining machine

- steam consumption: 450kg/T oil

- phosphoric acid:

- electric consumption: 28kwh/T oil

- Bleaching earth consumption: 5~50Kg/Toil

- Waste bleaching earth oil content: <35%

- Deodorization loss consumption: ≤0.5%

QIYI Machinery sets of small scale cooking oil unit equipment won the national patent (patent number: ZL 99 252888.7), is currently developing the third generation of our edible oil making machine.Our small scale oil refinery plant are great choice for small capacity oil refinery machine.The small scale oil refinery production plant can.

TINYTECH UDYOG is one of indonesia's reputed manufacturers and exporters of Cooking Oil Refinery Plants, Oil Mill Machinery Plants and Oil Extraction Plants. We possess technological expertise in the manufacturing of Edible Oil Refinery Plants and Vegetable Oil Refinery Plants.

Edible Oil Refinery Plant Batch Type Small Scale Palm Kernel Oil Refining Machine

- Type: Cooking oil refining, Cooking Oil Refinery Machine

- Use: Cooking Oil

- Condition: New, New, New

- Weight: According to your specifications

- Production Capacity: 30~500T/D

- deodorization: continuous deodorizaiton

- Voltage: According to your specifications

- Description: batch and continuous refining

- Min.Order Quantity: 1 Set/Sets

Our products include: Palm fruit /palm kernel pressing line: 1-2-3-5TPH small palm oil processing plant; 15-30-45-60-80-120TPH palm oil processing plant; 5-600TPD palm kernel oil processing plant; Palm oil refining: 1-2-3-5-10TPD batch palm oil refinery plant; 10-15-20-25-30-50TPD semi continuous palm oil refinery plant; 50-80-100-150-300.

Everything You Need To Know About Palm Oil Refinery Process

- Usage: Cooking Oil refining machine

- Type: Cooking oil refining machine

- Production Capacity: 100% Cooking oil refining machine

- Voltage: 220V/380V/440V

- Power(W): 10-50kw

- Dimension(L*W*H): According to processing capacity

- Weight: According to processing capacity

- Item: Cooking oil refining machine

- Raw Material: Sunflower Oil, Sesame Oil, Soybean Oil, Palm Oil, Coconut Oil,Peanut Oil, Castor Oil, etc

- Steam pressure: ≥1.2MPa

- Voltatile substance in crude oil: ≤0.3%

- Steam consumption in refining: ≤280kg/ton of oil

- Oil residue in waste clay: ≤25% of waste clay

- Solvent contain in crude oil: ≤200ppm

- Oil residue in meal: <1%

- Warranty: 2years

- Feature: High Oil Yield Efficiency

However, the crude palm oil that has been extracted contains unwanted impurities and requires a refining process to partially or eliminate them to produce edible oil. In the current scenario, palm oil is widely used in tropical countries in South East Asia, Africa, and parts of Brazil for cooking purposes.

- What is the palm oil processing plant project report 2025?

- IMARC Group’s report titled “Palm Oil Processing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue” provides a complete roadmap for setting up a palm oil processing plant.

- What is the Physical refining process for palm oil?

- The physical refining process is suitable for both crude palm oil and palm kernel oil. Our physical refining plants are built for large-scale production. Our process technology is based on a fully continuous and automatic fractionation of palm oil.

- How does government support palm oil production?

- By providing financial assistance, governing agencies are encouraging farmers to increase production, ensuring a stable supply. Palm oil production is also supported through tax incentives, which reduce operational costs for businesses.

- How a palm processing unit will increase palm oil production in India?

- October 204: Patanjali is set to establish a palm processing unit in Tripura, aiming to increase the local economy by enhancing palm oil production. March 2024: 3F Oil Palm launched India's first integrated oil palm processing unit, marking a significant step in the to increase domestic palm oil production in the country.

- Does palm oil produce pericarp & kernel oil?

- The palm oil fruit can yield two distinct edible oil – the pericarp and the kernel parts of the palm fruit. The physical refining process is suitable for both crude palm oil and palm kernel oil. Our physical refining plants are built for large-scale production.

- What are the analysis and analysis of palm oil processing plant costs?

- This includes the analysis and detailed understanding of palm oil processing plant costs, including capital expenditure (CapEx), operating expenditure (OpEx), income projections, taxation, depreciation, liquidity analysis, profitability analysis, payback period, NPV, uncertainty analysis, and sensitivity analysis.