Palm Oil Processing Production Line Palm Kernel Oil Press Machine

- Usage: Multi-functional

- Type: Oil refining plant

- Production Capacity: 160kg/h

- Voltage: 220V/380V

- Power(W): 4.3KW

- Dimension(L*W*H): 3750*850*1990MM

- Weight: 310

- oil processing plant: oil processing plant

- Raw Material: Sunflower Oil, Sesame Oil, Soybean Oil, Palm Oil, Coconut Oil,Peanut Oil, Castor Oil, etc

- Application: Oil Production Line

- Material: Stainless Steel SS304/316

- Function: Oil refining

- Advantage: Simple Operation

- Warranty: 12 Months

- Color: Customers' Request

- Cycle time: 2.5h

- Working time: 24 hours

Palm oil processing and palm oil mill Palm oil is an edible vegetable oil derived from the mesocarp (reddish pulp) of the fruit of the oil palms. It is naturally reddish in color because of a high beta-carotene content. Palm mesocarp oil is 49% saturated, while palm kernel oil is 81% saturated fats.

Palm oil production line consists of pre-treating, pressing or leaching, refining section. Palm oil pressing line produces oil with original flavor of Palms, rich in vitamin E, and has a long shelf life, which is suitable for small and medium commercial processors to start edible oil business.

High Quality Palm Oil Production Line For Big Capacity

- Usage: Cooking Oil

- Type: crude Cooking oil refinery production line

- Production Capacity: 98%

- Voltage: 220V/380V/440V

- Power(W): According to capacity

- Dimension(L*W*H): According to capacity

- Weight: According to capacity

- Color: Yellow

- description: Continuous automatic oil refining machine

- steam consumption: 450kg/T oil

- phosphoric acid:

- electric consumption: 28kwh/T oil

- Bleaching earth consumption: 5~50Kg/Toil

- Waste bleaching earth oil content: <35%

- Deodorization loss consumption: ≤0.5%

Sourcing Guide for Palm Oil Production Line: China manufacturing industries are full of strong and consistent exporters. We are here to bring together China factories that supply manufacturing systems and machinery that are used by processing industries including but not limited to: oil making machine, oil press machine, oil processing machine.

Palm Kernel Processing Plant Customized for You. According to different production capacity and customers’ different requirements on the products, our company can make rational choice and combination of palm kernel oil production processes, choose the best technological process, as well as sophisticated equipment manufacture and automatic control system to provide customers with perfect.

Complete Palm Oil Production Line. Palm Oil Mill

- Usage: Cooking Oil

- Type: Seed Roaster

- Cooking oil refining machine: silver

- Main export countries: Asia,Africa,Latin Americ...

- Processing: batch-type or semicontinuous

- Electric consumption: 28Kwh/T oil

- soften water: 150Kg/T oil

- Phosphoric acid: 2~3 kg/T oil

- Bleaching earth consumption: 3-5Kg/Toil

- Refining rate: refining consumption 1%

- Waste bleaching earth oil content: 25% to 35 %

- Circulating water cooling water yield: 150M3/H

Capacity 1 TPD to 5,000 TPD. The Palm oil production line includes cleaning, shelling, kernel separation, cooking, pressing, filtering, extracting, refining, and packing. Some steps can be customized based on specific requirements, fully automated or semi-automatic options for varying budget levels.

Palm seed oil production line How to make Palm oil using Palm oil production machine? Palm seeds is a common oilseeds, in which there are 45-54% oil content.

The Ultimate Guide To The Palm Oil Production Process

- Usage: Cooking and Cooking refining machine by CE approved

- Type: Cooking Oil Refinery Machine

- Production Capacity: 45 sets per year

- Voltage: 380V/440V

- Power(W): 30KW

- Dimension(L*W*H): 1200*2800*1200mm

- Weight: 500TON

- Usage: Cooking and Cooking refining machine by CE approved

- oil clolor: yellow

- advantage: save energy

- bleaching earth consumption: 5-50kg/t oil

- decolor function: remove the bad color

- deodor function: remove the bad smell

The role of palm oil refinery plants. PALM OIL REFINING. Crude palm oil comprises the products of hydrolysis and oxidation as well as unwanted flavours and colours. Palm oil refinery plants are designed to eliminate these undesirable components. Palm oil refining involves four major steps. Step 1: degumming.

Maize Corn Germ Oil Pressry Cooking Oil Processing Machine

- Usage: Cooking Oil

- Type: Cooking oil extraction machine

- Production Capacity: 10T-3000T/D

- Voltage: 220V/380V/440V

- Power(W): Acorrding to Cooking oil extraction machine capacity

- Dimension(L*W*H): Acorrding to Cooking oil extraction machine capacity

- Weight: Acorrding to Cooking oil extraction machine capacity

- product name: Cooking oil extraction machine / Cooking oil refining machinery

- Electric Consumption: 28Kwh/T Oil

- Soften Water:

- Phosphoric Acid:

- Bleaching Earth Consumption:

- Refining Rate:

- Waste Bleaching Earth Oil Content:

- Circulating Water Cooling Water Yield:

- Supplier Type:

- Warranty: 12 months

Our Sinoder Indutech Machine supply the complete set of Cooking oil pressry including Palm oil production line, palm oil production line, soya bean oil production line, Palm oil production line, cotton seeds oil production line, maize corn germ oil production line, clamelia oil production line, rapeseeds oil production line, canola oil production line, Palm cropra.

- What is palm oil production line?

- Palm oil production line includes three sections, palm oil pressing plant, palm oil refinery plant and palm oil fractionation plant. As the manufacturer of the palm oil production line, we can offer the whole line or part of the palm oil production line for different capacities with turnkey services.

- What is palm oil refining process?

- The refining process includes degumming, deacidification, decolorization and deodorization, obtaining high quality refined palm oil. Palm oil fractionation equipment can separate palm oil into soft fat and hard fat by controlling the cooling and crystallization process of palm oil.

- How is palm oil processed?

- For crude palm oil processing, it generally required complete processes such as sterilization, threshing, cooking, pressing, washing, purification, and drying. Sterilization as the first step in palm fruit pressing is critical to the quality of the final production-- palm oil.

- How is crude palm oil reprocessed?

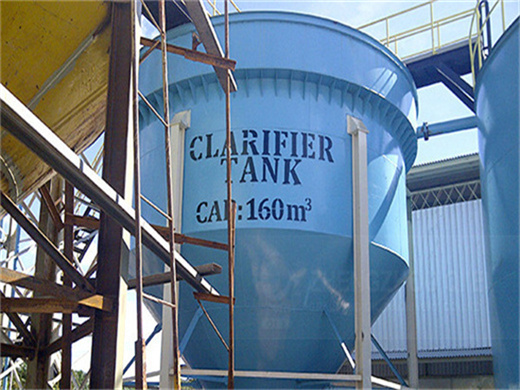

- The slag at the bottom of the clarification tank will also enter the centrifuge to recover the crude palm oil inside, and finally it will be vacuum dried and cooled to about 45 ℃ for storage. Crude palm oil into edible oil requires refining process, by removing gums, oxides, color and odor from the crude oil.

- What are the different types of palm oil fractionation temperature?

- There are three common palm oil fractionation temperatures: 18°C, 24°C, and 36°C. Dingsheng Machine adopts the palm oil dry extraction process. The new palm oil extraction complete sets of equipment include new type crystallizing tanks, diaphragm filters, and PLC automatic control systems.

- What is a palm oil press machine?

- Reliable palm oil press machine with simple operation, gaining a good reputation in Africa and South America. The main products of the palm fruit plant are palm kernels and crude palm oil, and the processing capacity is about 60 to 100 tons of palm fruit bunches per hour.