Palm Kernel Cracker And Separator Machine Running

- Usage: any kinds of seeds

- Type: Cooking oil solvent extraction equipment

- Production Capacity: Cooking oil production machine

- Voltage: Cooking oil production machine

- Power(W): according the capacity of Cooking oil production machine

- Dimension(L*W*H): according the capacity of Cooking oil production machine

- Weight: according the capacity of Cooking oil production machine

- color: Yellow

- capacity: 20-300TPD Cooking oil production machine

- madel: Cooking oil production machine

- function: Cooking oil production machine

- extractor system:

- Usage:

- solvent name:

- residual oil content: maxmum 1%

- material:

- Packaging Detail:

The palm kernel cracker machine is very popular in small capacity palm kernel oil mill and large capacity palm kernel oil plant in Nigeria, Liberia, Malaysia, Indonesia, Thailand and etc. PREV: Traditional VS modern palm oil processing machine

Our Oil Machinery sets of small scale Palm Oil Refining Unit equipment won the national patent (patent number: ZL 99 252888.7), is currently developing the third generation of our edible oil making machine. Our small scale palm oil refinery plant are great choice for small capacity oil refinery machine. The small scale palm oil refining.

Palm Oil Processing Equipment/Palm Oil Refinery Plant/Palm Oil Processing Plant

- Usage: Cooking Oil refinery

- Type: Cooking oil refinery

- Production Capacity: 1T~10T/D

- Voltage: 380V

- Power(W): according to capacity

- Dimension(L*W*H): depend on capacity

- Weight: according to capacity

- Item: Cooking oil refinery

- Application: various crude oil like Cooking oil

- Operating ways: safe and simple

- Residual oil in cake: low

- Oil grade: high

- Brand: Qi'e

- Refining technics: batch refining and semi-continuous

- Moisture and volatile: 0.08%

palm oil turn-key project epc QI’E has rich experience in general contracting of EPC project. With excellent product quality, worry-free project services and comprehensive project management, many domestic and foreign companies have selected QI’E, and all have been successfully finished.

Update or change your broswer if can't play here.Download Mini palm oil mill in Indonesia video. This is simple designed palm oil mill, which is designed according to the customer requirements.Due to the oil palm planting structure influence, many Africa customer requires small capacity palm oil production process machine, while, in the international market, few company can do this small.

Palm Oil Mill Plant Setup Guide In Indonesia For Business

- Usage: Cooking Oil

- Type: Cooking Oil Refinery Machine

- Automatic Grade: Semi-Automatic

- Production Capacity: 100%

- Voltage: 220V/380V

- Power(W): 7.5kw

- Dimension(L*W*H): Based on Oil Press Machine capacity

- Weight: 1200kg

- Product name: refined edible cooking Cooking oil making line price

- Advantage: Energy Saving

- Warranty period: 12 months

- Application range: Oil -bearing Material

- Function: Refining Vegetable Oil

- Item: Vegetable Oil Refining Machines

- Use for: Vege

- Raw Material: Sunflower Oil, Sesame Oil, Soybean Oil, Palm Oil, Coconut Oil,Peanut Oil, Castor Oil, etc

- Section: Oil Refinery Machine Section

- Product: National Oil Standard

The Indonesia Palm Oil Processing Plant Business Feasibility Study looks at assessing the potential feasibility of establishing a palm oil milling plant in Indonesia. It provides investors with comprehensive information by examining the country's abundant palm resources, demand trends in the palm oil market, and technological and environmental.

Bleaching Section in palm oil refinery Palm oil bleaching section is mainly used to remove oil pigment, residual soap and metal ions during palm oil milling process. Deodorization Section in palm oil refinery Palm oil deodorization section composes of part of crude palm mill plant processing equipment. It plays important part in improving oil.

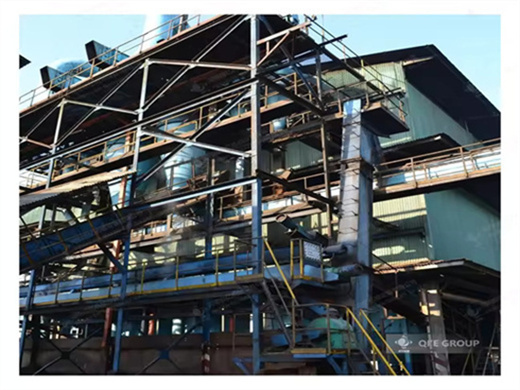

New Palm Oil Refinery In Indonesia Under Construction

- Usage: Cooking Oil

- Type: Cooking Oil Refinery Machine

- Production Capacity: 100TPD

- Voltage: 230V-380V-430V

- Power(W): 40kw/h

- Dimension(L*W*H): 20m*16m*15m

- Weight: 30tons

- After-sales Service Provided: Overseas third-party support available

- Machine type: crude oil refined Cooking oil machines and oil refining machine

- Machine application: crude Cooking oil

- Operation time: 24hours

- Electrical control: PLC control

- Workers needed: 2-3persons

- Machine material: carbon steel or stainless steel

- Power consumption: 22KWH/T oil

- Steam consumption: less than 300kg/t oil

- Soft water consumption: about 160kg/h

- Warranty period: 1year

Cargill is building a new US$200 million (170 million) palm oil refinery in Indonesia. The new plant in Lampung will accelerate Cargill’s efforts to develop a sustainable palm supply chain and provide verified deforestation free products to customers.

Everything You Need To Know About Palm Oil Refinery Process

- Type: Cooking oil refinery

- Use:

- production type: Cooking oil refinery

- type: complete equipment

- description: continuous

- steam consumption: 450kg/T oil

- phosphoric acid:

- electric consumption: 28kwh/T oil

- Bleaching earth consumption: 5~50Kg/Toil

- Waste bleaching earth oil content: <35%

- Deodorization loss consumption: ≤0.5%

However, the crude palm oil that has been extracted contains unwanted impurities and requires a refining process to partially or eliminate them to produce edible oil. In the current scenario, palm oil is widely used in tropical countries in South East Asia, Africa, and parts of Brazil for cooking purposes.

- Why is equipment layout important for palm oil mills in Indonesia?

- In the construction of palm oil mills in Indonesia, a reasonable palm oil factory plant and equipment layout design is crucial for improving production efficiency and operational safety. Proper equipment layout not only affects the ease of maintenance and repair, but also has a profound impact on the construction investment and economic efficiency.

- How to start a palm oil processing plant in Indonesia?

- Establishing a palm oil processing plant in Indonesia is a lucrative opportunity, and a careful understanding of the associated costs is key to success. Key steps include the cost of acquiring suitable land, infrastructure costs, processing machinery costs, and various management and operational costs. Plant Layout and Design:

- What is palm kernel oil production machine?

- Palm kernel oil production machine is suitable for both small and large palm kernel oil mill plant. The complete set of palm kernel oil production machine includes palm kernel oil pretreatment and press machine, palm kernel cake solvent extraction plant and palm kernel oil refinery machine. 1. Raw Materials Reception Station

- What is palm oil refining equipment?

- Palm oil refining equipment includes oil-water separation equipment, deodorization equipment, bleaching equipment, etc. to improve the purity and quality of palm oil. 2. Consider Palm Oil Storage And Packaging Areas

- What is a palm oil processing machine?

- The complete set palm oil processing machine includes palm oil extraction process (how palm oil is extracted), Palm Kernel Oil Extraction Process and palm oil/palm kernel oil refining process. Oil palm is an important tropic oil seed plant. The palm oil content is very high: common fresh fruit: 45~50%, palm kernel: 50~55%.

- What is palm oil extraction machine?

- Manufacture Palm oil extraction machine to extract palm oil from palm fruit,oil refinery plant & expeller,provide a turnkey project of palm oil mill.