An Extensive Resource On The Edible Oil Refining Process

- Usage: Cooking Oil

- Type: small oil refinery equipment

- Production Capacity: 1-5000TPD

- Voltage: 220V, 380V

- Power(W): According to your capacity

- type: small oil refinery equipment

- Usage: extract/refining oil Cooking

- features: high output, good quality crude edible oil refinery

- aim: provide the quality and realible product for you

- product: reach to the national oil standard

- moisture and volatile matter(%): less than0.05 after small oil refinery equipment

- insoluble impurity(%): less than 0.05

- residual solvent content in oil: no after small oil refinery equipment

- acid value(mg/g): less than 0.20

- FFA: less than 3.5%

The Importance of Edible Oil Refining. Refining edible oils is essential to produce high-quality oils that meet consumer demands and regulatory standards. Unrefined oils may contain impurities, such as phospholipids, free fatty acids, pigments, and volatile compounds, which can affect the taste, odor, appearance, and shelf life of the final product.

The company offers palm oil, oil palm seedlings, palm cake, palm fiber, crude palm oil, kernel oil, and fiber and nut shells. It produces around 3 to 5 Tons of palm oil per hectare. Recently, Oil Palm indonesia has set up a kernel oil factory for the extraction of palm kernel oil at Yeroor, indonesia.

Everything You Need To Know About Palm Oil Refinery Process

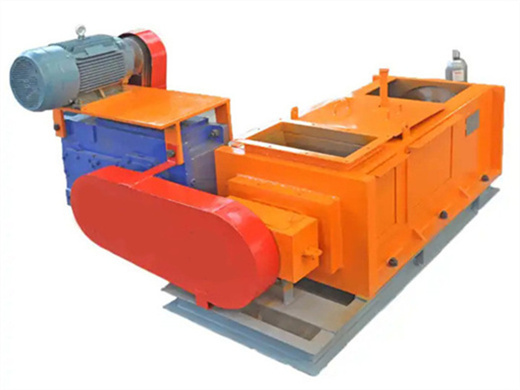

- Type: oil dewaxing machine

- Use: Cooking oil dewaxing machine

- Product name: Cooking oil dewaxing machine

- Material: Stainless Steel and carbon steel

- Voltage: According to customers

- capacity: 10-1000tpd

- Quantity: according to the capacity

- Application: rice bean oil /Cooking oil/Cooking oil etc.

- Usage: grade one edible oil,salad oil

- Warranty: 1 Year

- Raw Material: Sunflower Oil, Sesame Oil, Soybean Oil, Palm Oil, Coconut Oil,Peanut Oil, Castor Oil, etc

- Price: Negotiation

The crude palm oil is gathered from the mesocarp of the palm oil. However, the crude palm oil that has been extracted contains unwanted impurities and requires a refining process to partially or eliminate them to produce edible oil. In the current scenario, palm oil is widely used in tropical countries in South East Asia, Africa, and parts.

Find here online price details of companies selling Palm Oil Refinery. Get info of suppliers, manufacturers, exporters, traders of Palm Oil Refinery for buying in indonesia.

Physical And Chemical Process In Palm Oil Refining Plant

- Usage: vegetable oil

- Type: Cooking Oil Refinery Machine

- Production Capacity: 10-100TPD

- Voltage: Standard

- Power(W): Standard

- Dimension(L*W*H): Standard

- Weight: Standard

- Product name: mini oil pressing equipment oil refining machinery for sale

- Raw Material: Sunflower Oil, Sesame Oil, Soybean Oil, Palm Oil, Coconut Oil,Peanut Oil, Castor Oil, etc

- Advantage: Simple Operation

- Warranty: 1 Years

- Feature: High Output

- Color: as require

It adopts vacuum system to remove the impurities and color pigments from the crude palm oil and crude palm kernel oil. Deodourising process; The palm oil and palm kernel oil are steamed at a temperature of 240°C to 260°C to get away the odors and tastes, and then they are cooled into room temperature (about 55°C) for further use.

indonesia imports roughly 60% of its edible oil consumption, and palm oils (crude + refined) account for nearly 60% of edible oil imports. As a result, fluctuations in imports and international prices are transmitted to domestic edible oil prices. The current increase in edible oil prices is primarily due to high and rising international edible […]

Exclusive: Indonesian Refiners Cancel Palm Oil Contracts On Duty

- Usage: Cookings oil

- Type: Cooking Oil Refinery Machine

- Production Capacity: 20-2000TPD

- Voltage: 380V

- Power(W): Standard

- Dimension(L*W*H): standard

- Weight: standard

- Application: Cooking Oil Refinery

indonesia earlier this month raised the basic import tax on crude and refined edible oils by 20 percentage points, which effectively increases the total import duty on crude palm oil to 27.5% from 5.5%.

A Comprehensive Guide To The Palm Oil Production Process

- color: silver

- Main export countries: Asia,Africa,Latin Americ...

- Processing: batch-type or semicontinuous

- Electric consumption: 28Kwh/T oil

- soften water: 150Kg/T oil

- Phosphoric acid: 2~3 kg/T oil

- Bleaching earth consumption: 3-5Kg/Toil

- Refining rate: refining consumption 1%

- Waste bleaching earth oil content: 25% to 35 %

- Circulating water cooling water yield: 150M3/H

The Cost of Setting up a Small to Med, ABC Mach. 1Ton, 2Ton, 5Ton, 10Ton, 15Ton, 20Ton, 30Ton. Application. Process almost all kinds of crude oil for edible purpose: vegetable oil, palm oil, palm kernel oil, castor oil, sunflower oil, rice bran oil, soybean oil, sesame oil, cottonseed oil, canola/mustard oil, peanut/groundnut oil, etc. Machine Cost. $21,000~$115,000 ( the exact price is based

10tpd small cottonseed oil processing plant installed in ivory coast. Product Using: Producing Cotton Seed Oil; Type: Cotton Seed Oil Processing Plant; Main Machinery: Cotton Seed oil press machine; Automatic Grade: Automatic; Production Capacity: 30T-300T/D; Model Number: JXHHT668; Voltage: 220V/380V; Power(W): Accoding to your

The refining process is like giving it a spa treatment. Crude palm oil, as the name suggests, isn't perfect yet. It contains some things we don't want, like impurities and odors. That's where refining comes in. Hence, in the second stage of palm oil process, we discuss refinery process of crude palm oil. Refinery of Crude Palm Oil

- Why is Cargill Building a new palm oil refinery in Indonesia?

- Cargill is building a new US$200 million (€170 million) palm oil refinery in Indonesia. The new plant in Lampung will accelerate Cargill’s efforts to develop a sustainable palm supply chain and provide verified deforestation free products to customers.

- Where is Cargill Building a new palm oil refinery?

- SINGAPORE—June 3, 2021— Cargill is building a new US$200 million palm oil refinery in Lampung, Indonesia, which will accelerate Cargill’s efforts to develop a sustainable palm supply chain and provide verified deforestation free products to customers.

- Which is the largest palm oil refinery in Padang?

- PT PRC, the largest palm oil refinery in Padang, is a multi-product refinery capable of producing palm olein, stearin, biodiesel and fatty acid. Currently, the refinery has a refining capacity of 1.2 million MT per annum, which will double to 2.4 million MT upon completion of its expansion.

- What will Indonesia's new refinery do?

- The new refinery will play a key role in connecting sustainable crude palm oil production in Indonesia to demands in North America and Europe through a fully integrated supply chain from plantation to customer.

- How will a new palm oil refinery benefit Indonesia?

- With the new refinery, the firm will be able to meet customers’ evolving expectations around sustainability and transparency by guaranteeing traceability to plantation and improved product quality standards. Palm oil has experienced strong demand in recent years, with Indonesia as the largest producer and exporter.

- Why is Cargill launching a palm oil refinery in Lampung?

- The refinery project in Lampung builds on Cargill’s mission to provide greater insight into the local and global palm supply chain and will further strengthen Cargill’s position as a supplier of choice for sustainable palm oil. Media Contact: [email protected]