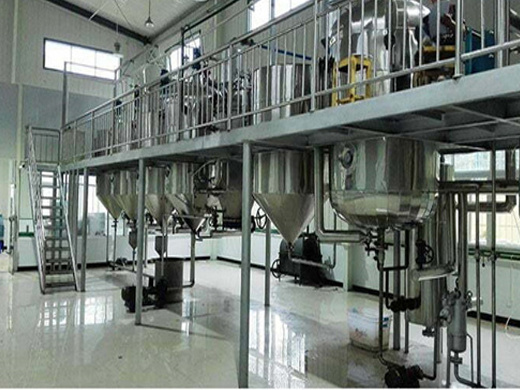

Types Of Cooking Oil Refining Machine Edible Oil Refinery Plant

- Usage: Cooking Oil

- Type: Cooking Oil Refinery Machine

- Production Capacity: 98%

- Voltage: 380V

- Power(W): Capacity

- Dimension(L*W*H): depend on Cooking oil mill per day capacity

- Weight: depend on Cooking oil mill per day capacity

- Item: cost of installing crude Cooking oil refinery

- Materials of the equipment: stainless steel and carbon steel

- Cooking reception system: sterilizer

- Key word: Cooking oil mill

- Distillation range: 68-75℃

- Warrenty: 12 months

- Crude oil moisture and volatile matter: Less than 0.30%

- Indine value: 44-46gl/100g

- Transparency: 500c

- Acid value: less than 1.0mg koh/g

It is available for refining palm oil, palm kernel oil, corn germ oil, Palm oil, Palm oil, Palm seed oil, rapeseed oil, rice bran oil, Palm oil, etc. Contact Us. Please kindly leave your requirements in detail or contact us via +86 13526627860. Our professional project manager will contact you within 24 hours.

Name: new technology large oil production oil refinery machines; Palm kernel oil processing machine (1-1000tpd) Because of palm nut shell is hard, if pressing directly without kernel and shell separation, machine will wear very fast. So

Palm Kernel Oil Refinery Plant

- Usage: Cooking Oil

- Type: Cooking oil refining mill

- Production Capacity: 1-3000T/D

- Voltage: 220V, 380V

- Power(W): Accoding to your capacity

- Supplier type: Cooking oil refining mill

- Features: high quality Oil smell remover

- Taste,smell: Has the inherent oil taste and smell,non odor

- Moisture and volatile matter%: less than0.2

- Insoluble wastes: less than 0.2

- Acid value mgKOH/g: less than 3

- Peroxide value mmol/kg: less than 6

- Saponified matter content%: less than 0.03

- Solvent residual(mg/kg): 50

- Heating test 280 degree: Little precipitate,lovibond colorimetric

This is the liquid component of the palm kernel oil obtained after refining. 2) Palm Kernel Stearin. This is the solid portion of the palm kernel oil obtained after refining. Palm kernel oil, palm kernel olein and palm kernel stearin have various individual applications such as margarine making, confectioneries, bakery products, coffee whitener.

What we serve is equally important to what we offer. With over 25 years of existence in our field, we have gained incredible expertise in providing services in terms of process development, technical evaluation studies, design of plants, oil refinery equipment, improvement and expansion of existing facilities, studies from the point of view of pollution prevention, energy conservation and.

Palm Kernel Oil Refining Plant Palm Oil Mill Machines

- Usage: Cooking Oil refinery machinery

- Type: Cooking Oil Refinery Machine

- Production Capacity: 100% Cooking oil refinery machinery

- Voltage: 220V/380V/440V

- Power(W): Depand on your capacity

- Dimension(L*W*H): Depand on your capacity

- Weight: Depand on your capacity

- Raw Material: Sunflower Oil, Sesame Oil, Soybean Oil, Palm Oil, Coconut Oil,Peanut Oil, Castor Oil, etc

- Application: cooking oil refining

- Common capacity: 1-1000TPD

- Character: semi-continuous,fully continuous

- Certificate: CE/BV/ISO9001

- Advantage: high oil yield

- Material: stainless steel/carbon stell

Palm kernel oil contains soap grade and food grade.The process of Palm kernel oil refinery is to refine the crude edible oil, to remove gossypol, protein, phospholipid, grume, moisture and other impurities, in order to reach the purchase of food and storage.The process of palm kernel oil refinery includes mechanical refinery method, chemical.

A wide variety of palm kernel oil extraction machine options are available to you, There are 5,343 palm kernel oil extraction machine suppliers, mainly located in Asia. The top supplying countries or regions are China, indonesia, and Indonesia, which supply 92%, 7%, and 1% of palm kernel oil extraction machine respectively.

Oils Fats Refining Equipment And Turnkey Plants

- Type: oil refining machine

- Use: refine oil from Cooking seed

- Material: Stainless steel

- Color: According to customer requirements

- Continuity: batch reactor

- Refining method: physical, chemical or physical-chemistry refinery

- Trade Terms: EXW,FOB,CFR,CIF

- Oil Purity: More than 99.8%

- price: negotiation

- Motor power: 38kw

- Voltage: 380V

- Oil attrition rate: 4%-10%

We can provide edible oil refining plant equipment with capacity ranging from 50 t/d to 4,000 t/d for Palm oil, rapeseed oil, Palm seed oil, cottonseed oil, rice bran oil, palm oil, corn oil, Palm oil, linseed oil, animal fats and oils, chicken fat, butter, fish oil and etc. Refining is the last step in edible oil processing.

Edible Oil Refinery, Vegetable Oil Refinery, Cooking Oil Processing Machine

- Usage: crude Cooking cooking oil refining plant

- Type: Cooking Oil Refinery Machine

- Production Capacity: 1-1000TPD

- Voltage: 220V/380V/415V

- Power(W): 1-30kw

- Dimension(L*W*H): According the capacity

- Weight: According the actual situation

- Keywords: Crude Cooking cooking oil refining plant

- Raw Material: Sunflower Oil, Sesame Oil, Soybean Oil, Palm Oil, Coconut Oil,Peanut Oil, Castor Oil, etc

- Warranty: 12 Months

- Advantage: Energy Saving and environment protection

- Supplier strength: with 30 years experiences

- Machine Material: Part of are stainless steel and carbon steel

- Color: According the customer requirements

- Residual: Less than 2%

- Supplier: Group manufactory

- Product name: crude Cooking cooking oil refining plant

Shutdowns, Turnarounds, and Outages (STO) are commonly used terms, often interchangeably, to describe a planned or unplanned period of time in which a plant/facility, unit, or piece of equipment is out of service. In many process industries (e.g., refining, petrochemicals,

Shutdowns, Turnarounds, and Outages (STO) are commonly used terms, often interchangeably, to describe a planned or unplanned period of time in which a plant/facility, unit, or piece of equipment is out of service. In many process industries (e.g., refining, petrochemicals,

A first climbing step of the big ladder! A Buyer and Seller can enjoy good relations only with the help of one clause, and that is Quality. TINYTECH has been providing excellent products and services to a wide array of customers for nearly 30 years!

- What is a palm kernel oil processing machine?

- The full set of Palm Kernel Oil (PKO) Processing Machines include Husker, Crusher, Cooker, Oil Press Expeller, Oil Filter, Oil Refinery Machine, etc.. However, due to the small processing capacity of a single oil press, a large scale palm kernel oil mill plant require a large number of palm kernel oil expellers.

- What is palm oil extraction machine?

- Manufacture Palm oil extraction machine to extract palm oil from palm fruit,oil refinery plant & expeller,provide a turnkey project of palm oil mill.

- How palm kernel oil is extracted?

- However, due to the small processing capacity of a single oil press, a large scale palm kernel oil mill plant require a large number of palm kernel oil expellers. Detailed palm kernel oil extraction process by mechanical pressing method is as follow. Palm Kernel Oil (PKO) Processing Flow Chart

- How to refine palm kernel oil?

- In order to achieve this goal, the palm kernel oil refining machine will be needed. In order to get high quality refined vegetable oil, we need to through four steps, they are: degumming, deacidification, decolorization/bleaching and deodorization.

- How is palm oil processed?

- The processing is done depending on the volume of the fruit bunches and can be divided in small scale palm oil mill plant, medium scale palm oil mill plant, and large-scale palm oil mill plant. The minimum limit for a small scale palm oil production line is that it only processes of 2 tons of fresh fruit bunches per hour.

- Which palm oil processing plant is considered a large scale industry?

- Any palm oil processing plant that has processing volumes of palm fruits above 2 tons is considered as medium scale or large scale industry. Most of the information can be found on the large scale and medium scale palm oil processing unit because most of the development has been done in these two zones.