The Ultimate Guide To The Palm Oil Production Process

- Usage: edible oil refinery equipment cooking

- Type: edible oil refinery equipment cooking, automatic

- Production Capacity: 1-1000TPD

- Voltage: 220V,380V,440V

- Power(W): 28kw

- Dimension(L*W*H): according to the capacity

- Weight: according to the capacity

- Labor need: 1staff

- Dimension: according to the capacity

- Color: customerization

- Frequency: 50HZ,60HZ

- Raw Material: Sunflower Oil, Sesame Oil, Soybean Oil, Palm Oil, Coconut Oil,Peanut Oil, Castor Oil, etc

- End product: refined oil

- Package: container special for Cooking oil refinery plant

- Engine: diesel, solar, oil,steam

The role of palm oil refinery plants. PALM OIL REFINING. Crude palm oil comprises the products of hydrolysis and oxidation as well as unwanted flavours and colours. Palm oil refinery plants are designed to eliminate these undesirable components. Palm oil refining involves four major steps. Step 1: degumming.

Rapeseed oil. Rapeseed oil is one of the most widely consumed vegetable oils and it is extracted from the seeds of the rapeseed. This oil is also found in a wide variety of processed foods, it is mostly used for frying and baking. (If you want to know how to make rapeseed oil, you can read: Rapeseed screw oil press machine)

How To Start A Palm Oil Milling And Processing Plant

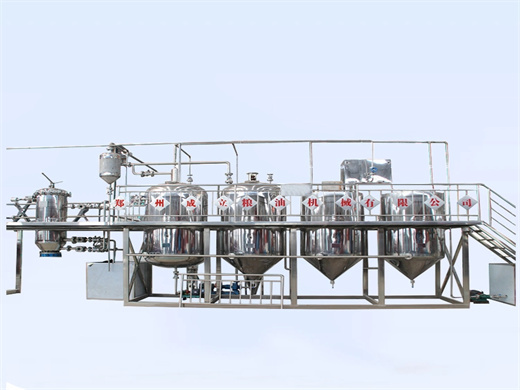

- Usage: crude Cooking oil refinery plant

- Type: crude Cooking oil refinery plant

- Production Capacity: 10T-500T/D

- Voltage: 380v or according to the local voltage

- Power(W): According to crude Cooking oil refinery plant capacity

- Dimension(L*W*H): According to crude Cooking oil refinery plant capacity

- Weight: According to crude Cooking oil refinery plant capacity

- Automatic grade: Full automatic

- Phosphoric: 2~3 kg/T Oil

- Supplier: Manufacturer

- Guide install service: Yes

- After sale service: Engineer abroad service

- Capacity: 10-500TPD

Modern palm oil processing process harvested palm fruits into final grade palm oil with little or no waste and minimal use of human power.Using machines, the process typically involves sterilizing and threshing the bunches to free the palm fruit, mashing the fruit and pressing out the crude palm oil.The crude oil is further treated to purify and dry it for storage and sale in both local and.

Palm Oil Refining Machine, Palm Oil Production Line. For example, if your palm fruit processing capacity is about 1-5 tons/hour, you can choose the standard configuration of palm oil production line equipment, mainly by the fermentation tank, fruit extractor, mashing tank, palm oil press, rotary sieve and plate and frame filter and other equipment, the investment is generally from hundreds.

Palm Oil Mill Plant Production Line

- Usage: Cooking Oil

- Type: whole or parts of crude Cooking oil refinery equipment

- Production Capacity: 100%

- Voltage: 380V

- Power(W): according to capacity

- Dimension(L*W*H): various with capacity

- Weight: changed with capacity

- Raw Material: Sunflower Oil, Sesame Oil, Soybean Oil, Palm Oil, Coconut Oil,Peanut Oil, Castor Oil, etc

- Product: to make crude Cooking oil, red Cooking oil or refined Cooking oil

- Solvent name: n-hexane

- Capacity: from 5T to 2000T crude Cooking oil refinery equipment

- Oil content in Cooking: about 26% of the Cooking brunch

- Oil residues: less than 1%

- Function: getting Cooking oil and refining it

- Manufacturing experience: 19 years experience in edible oil field

- Material of equipment: stainless steel and carbon steel

The palm oil degumming and deacidification process uses a washing method to separate soap residual from mixing oil, providing preparation for the next step palm oil refinery machine. Bleaching Process. The palm oil bleaching process is mainly used to remove oil pigment, residual soap, and metal ions during palm oil refining machine.

QIYI Machinery sets of small scale cooking oil unit equipment won the national patent (patent number: ZL 99 252888.7), is currently developing the third generation of our edible oil making machine.Our small scale oil refinery plant are great choice for small capacity oil refinery machine.The small scale oil refinery production plant can.

Edible Crude Palm Oil Neutralizer Refinery Machine In Mozambique

- Usage: edible oil

- Type: Cooking Oil Refinery Machine

- Production Capacity: 98%-100%

- Voltage: 220V/380V/440V

- Power(W): 22kw

- Dimension(L*W*H): 2000x1400x1850mm

- Weight: 10tons

- Product name: Cookingbean oil refinery plant

- Raw Material: Sunflower Oil, Sesame Oil, Soybean Oil, Palm Oil, Coconut Oil,Peanut Oil, Castor Oil, etc

- Application: Cooking...

- Function: making edible oil

- Character: the most professional manufactuer of Cooking oil machine

- Advantage: 36 years

- Warranty: 365 days

- Color: as you require

Machine Type: palm oil refinery machine, Production Capacity: 15 ~ 33 ton/day, Dimension(L*W*H):Depends on different equipment, Voltage:380V/3 phase, Our Advantage: 50 Years Production experience, Working time: Reflexiable, Raw Material: palm, Market: mozambique

High Quality Palm Oil Production Line For Big Capacity

- Usage: 3tpd Cooking oil refining plant

- Type: 3tpd Cooking oil refining plant

- Production Capacity: 1-100T/D

- Voltage: 380V/440v

- Power(W): 20-50KW

- Dimension(L*W*H): depond on capacity

- Weight: depond on capacity

- Main export countries: Asia,Africa,Latin American,Malaysia...

- Packaging: Glass Container,Plastic Container

- Grade: first Grade

- refined oil: 1st grade Cooking oil

- oil content: 35%-48%

- fatty: 40~60.7

- protein: 20~37.2

- phosphlipid: 1.25~1.75

- saccharides: 5~15

- Refiney type: 3tpd Cooking oil refining plant

201 202, Omex Chambers, Rajarshi Shahu Maharaj Marg, Andheri (East),Mumbai 400069, Maharashtra, India Phone : 07317126521

We possess technological expertise in the manufacturing of Edible Oil Refinery Plants and Vegetable Oil Refinery Plants. Our machinery is suitable for crushing and refining of all types of oil seeds such as groundnut, sunflower, soyabean, palm kernel, mustard, copra, sesame seed, rapeseed, linseed, cotton seed etc.

Process: The palm fruits are sent to a digester where they are heated to 85°C?90°C and mashed through stirring and squeezing, to destroy the palm skin, separate the palm pulp and nuts, and pound the palm pulp, helping to release the oil in the palm oil pressing process. In small palm oil mill plants, the palm fruit digestion process is.

- What is palm oil refining?

- Palm oil refining is aim to remove phospholipids, FFA, pigment, gums, waxes, off-flavor and other impurities in the crude palm oil . The main process of palm oil refining processes are: degumming & deacidification , decolorization and deodorization. Chemical refining and physical refining of crude plam oil

- What are the products after crude palm oil refining process?

- After crude palm oil refining process, The palm oil refinery products is rbd palm oil and soaps. The refined palm oil can be sold directly or deep processed. If the refined palm oil need to be deep processed , the palm oil fractionation plant will be necessary. After palm oil fractionation process, we can get palm olein and palm stearin.

- What is the difference between chemical and Physical refining of palm oil?

- Chemical refining and physical refining of crude plam oil During palm oil refining process, there are two refining methods can be used, they are chemical refining of palm oil and physical refining of palm oil. The main difference between physical refining and chemical refining of palm oil lies in the way that how to remove FFA.

- How to obtain crude palm oil?

- Crude palm oil, the crude palm oil can be obtained by expeller or palm oil extraction machine Why crude palm oil need to be refined? What is palm oil refining ?

- How to get high quality palm oil?

- In order to get high quality palm oil, the crude palm oil need to be refined by palm oil refinery plant. Palm oil refining is aim to remove phospholipids, FFA, pigment, gums, waxes, off-flavor and other impurities in the crude palm oil .

- Why is crude palm oil difficult to introduce into the market?

- Because crude palm oil contains free acids (FFA), moisture, trace metals, and other impuries that limit its shelf life.So it is hard to introduce crude palm oil into the market. In order to get high quality palm oil, the crude palm oil need to be refined by palm oil refinery plant.