Edible Oil Filteration Machinery

- Usage: oil refinery manufacturer

- Type: oil refinery manufacturer

- Production Capacity: 1-500T/D

- Voltage: 380V-415V

- Power(W): depend on the mode of the Coconut Oil Machine

- Dimension(L*W*H): depend on the mode of the Coconut Oil Machine

- Weight: depend on the mode of the Coconut Oil Machine

- item: oil refinery manufacturer

- production process: pretreatment,extraction,refining

- Raw material: Coconut, Copra

- Waste Bleaching Earth Oil Content: 25% to 35 %

- Electric Consumption: 28Kwh/T Oil

- Soften Water: 150Kg/T Oil

- Phosphoric Acid: 2~3 kg/T Oil

- Bleaching Earth Consumption: 80-500KG/T Oil

- Supplier Type: oil refinery manufacturer

- Steel material: Stainless Or carbon steel

Edible Oil Filtration Machines At CbS Technologies, we take pride in introducing our advanced Disc Stack Separators an innovative solution engineered to meet the rigorous demands of the edible oil industry. Our separators are efficient, reliable, and sustainable alternatives to traditional paper or cloth filters, often requiring frequent replacements and maintenance. What is a Disc Stack

VO separators range was designed to increase oil yield and produce refined oil of better quality. Enhanced with a special feature manual Centrizoom paring disc outlet these centrifuges are ideal for degumming, neutralization and washing, they ensure optimal mixing and separation, allow to increase efficiency of the plant and to reduce production costs.

Vegetable Oil Centrifuge in Edible Oils and Fats Refining

- Usage: essential oil

- Type: essential oil extractor machine

- Production Capacity: 5TPD-100TPD

- Voltage: 220V/380V

- Dimension(L*W*H): 1200*600*2000mm

- Weight: 100kg

- Warranty: 1 Year, One Year

- Core Components: PLC

- Product name: essential oil extracting machine

- Raw material: flowers,herbs,etc.

- Function: essential oil distiller

- Application: flowers,herbs,etc.

- Material: 304 Stainless Steel

- Advantage: Energy Saving

- Item: Essential Oil Extractor

- Color: Sliver

The Essential Role of Vegetable Oil Centrifuges in Edible Oil Refining In the realm of edible oil refining, achieving the highest quality and purity of vegetable oils is paramount. Among the critical equipment used in this process, the vegetable oil centrifuge —also known as a disc stack centrifuge or vegetable oil separator—stands out for

It is widely used to separate water and solid in edible oils such as vegetable oil,coconut oil, olive oil, etc. Type GF tubular centrifuge separator is used for separating various emulsions, especially for liquid-liquid separation with slight gravity difference and liquid-liquid-solid separation with a little foreign matter.

type cold pressed coconut oil machine in ndola

- Usage: Coconut Oil, Cooking Oil

- Production Capacity: 4Kg/h

- Voltage: 220V/110V 60Hz/50Hz

- Dimension(L*W*H): 46*18*31cm

- Weight: 16

- Core Components: Motor

- Oil type: Coconut Oil

- Keyword 4: oil press for Coconut

- Keyword 9: Coconut oil press machine

- Keyword10: hydraulic oil press machine

crude oil refining machine; edible oil expeller machine; type cold pressed coconut oil machine in ndola . Production Capacity: 100kg/h-10000kg/h; Voltage: 220V/380V;

pretreating coconut oil, coconut kernel oil, coconut and olive oil as well as animal fats. This method of degumming aims to reduce bleaching earth consumption in the physical refining process, making this an extremely economical method. The crude oil is initially heated to the optimum process temperature in a heat exchanger. A

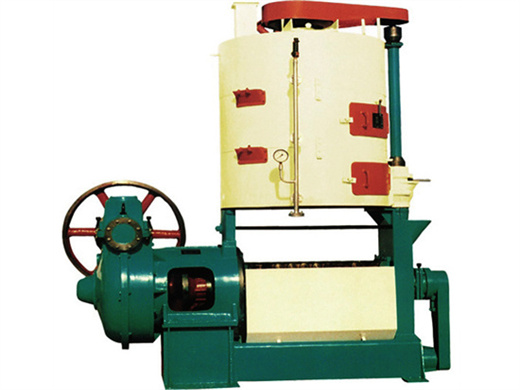

VCO virgin coconut oil tubular centrifuge machine

- Usage: cooking oil

- Type: China oil expeller

- Production Capacity: 150-250kg/h

- Voltage: 380V

- Power(W): 7.5Kw

- Dimension(L*W*H): 1950x1300x1900

- Weight: 950 kg

- Screw speed: Heater: staff requirement: space requirement: Package: Gear ratio: usage: features: Vacuum pump: Dimension: 1950x1300x1900

VCO virgin coconut oil tubular centrifuge machine,Reyes Machinery is a high-tech enterprise integrating consulting, R&D, production, sales and after-sales service for Centrifuge etc. +86-123-1234 5678

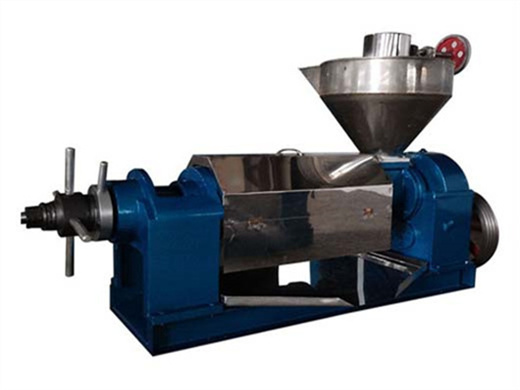

oil making machine in ndola edible oil machine supplier

- Usage: Coconut Oil, Cooking Oil

- Type: Coconut Oil Press Machine

- Production Capacity: depending on the raw materials

- Voltage: 380 v /220v

- Power: 4-7.5kw

- Dimension(L*W*H): 1800*1200*1500mm

- Weight: 1100kg

- diameter of screw: 100 mm

- speed: 37 r/min

- inner diameter: 102 mm

- main body power: 4-7.5 kw

- power of vacuum pump: 1.1kw

- power of heater(hot oil press ): 2.2 kw

- capacity: 150-230 kg/h for Coconut and Coconut

- Application: Coconut

- rate of oil of Coconut and Coconut: 42-53 %

- Advantage: low energy consumption

Name: machine oil press; Material: 304 Stainless Steel machine oil press; Model No: OC-H230; key words: machine oil press; Function: Press Fresh Palm, aloe and others; Capacity: 20-150KG/H machine oil press; features: high efficiency, cold press,dont break nutrition in oil; packaging: 1 set/standard export wooden case

- How vco75 Separator Works?

- It separates the raw virgin coconut oil into 2 phases, namely the virgin coconut oil and water. Tubular centrifugal separator VCO75 is used to further extract the virgin coconut oil from the raw virgin coconut oil via high speed centrifugal action.

- How does a coconut oil extraction machine work?

- This machine is used to further extract the virgin coconut oil from the raw virgin coconut oil via high speed centrifugal action. It separates the raw virgin coconut oil into 2 phases, namely the virgin coconut oil and water.

- Who are cocoman coconut machines?

- Based in Malaysia, a country where coconuts are one the main agricultural product, we have years of experience in designing and developing coconut machines focusing on qualities and reliabilities. Since 2003, we are one of the best known manufacturer and exporter of CoCoMaN coconut machines.

- Why do you need R&D for your coconut machine?

- Our R&D team gives better ROI by maximizing the processing capabilities and producing immediate results. We design coconut machines that cater to a variety of applications to maximize profitability. Qualified engineers provide after sales support to maintain the performance of your machines.