Total Cost To Set Up A Medium-Scale Palm Oil Production Line

- Usage: Cooking oil

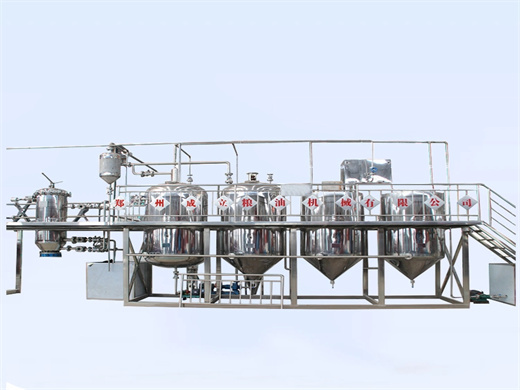

- Type: Cooking Oil Refinery Machine

- Production Capacity: 1-50T/D

- Voltage: 380V /440V or the local voltage

- Power(W): According to the capacity

- Dimension(L*W*H): According to the capacity

- Weight: According to the capacity

- Key word: Cooking oil refining machine

- Supplier type: Factory(more than 35 years experience)

- Capacity: 1-50T/D

- Materials: Carbon steel Q235 and stainless steel SS304/316

- Services: Three-D design and turnkey project

- After-sale services: Installation, debugging,trainning your workers

- Moisture and volatile: 0.08%

- Advantage: Professional engineer team in oil mill plant design

They are: 1-20tpd batch type palm oil refinery plant ; 20-50tpd semi-continuous palm oil refinery plant, 50-1000tpd fully continuous palm oil refinery plant. The specifications of the palm oil refinery plants are as follows:

They are 1-20tpd batch palm oil refining machine, 20-50tpd semi-continuous palm oil refining machine and 50-1000tpd fully-continuous palm oil refining machine. Various palm oil refining machines. In addition to the above machines for processing palm fruit into palm oil, we also need to use palm oil filling machine to store the processed palm.

Understanding Palm Oil Processing Plant Cost

- Type: continuously, complete continuous equipment

- Use: oil refining

- Delivery time: 45 days after deposit

- Capacity: 10-3000TPD oil refining machine

- Grade: grade 1--4

- Product: refined cooking oil

- Material: Carbon steel and stainless steel

- Raw Material: Sunflower Oil, Sesame Oil, Soybean Oil, Palm Oil, Coconut Oil,Peanut Oil, Castor Oil, etc

- Refining ways: Physical or chemical oil refining machine

- Function: refining pure edible oil

- Min.Order Quantity: 1 Set/Sets

Single Palm Oil Press Machine Price: Referring to single screw pressing type of palm oil processing machine, a small oil press is generally priced at around $2,000.00 $3,000.00, while for complex palm oil press machine for industiral oil mill plant, with a main motor of 18.5 kW and have a packing dimension of 255 x 170 x 205 cm, the price is.

IMARC Group’s report titled “Palm Oil Processing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue” provides a complete roadmap for setting up a palm oil processing plant. It covers a comprehensive market overview to micro-level information such as unit operations.

Cost To Set Up A Medium Palm Oil Processing Plant

- Usage: Cooking oil

- Type: Cooking Oil Refinery Machine

- Automatic Grade: Automatic, Automatic

- Production Capacity: 99%, 100%

- Voltage: 380V

- Power(W): 85KW

- Dimension(L*W*H): According to the specification

- Weight: 35ton, changed with the capacity

- Capacity: 3T to 200T

- Material of equipment: stainless steel and carbon steel

- Raw Material: Sunflower Oil, Sesame Oil, Soybean Oil, Palm Oil, Coconut Oil,Peanut Oil, Castor Oil, etc

- including: machines,installation,tech consulting after sales

- operattion: automatic and safe

- type: Cooking oil extraction equipment

Construction cost of a medium palm oil processing plant. The price level in each country and region is different, and this is mainly determined based on the actual local situation. 2. Cost of medium palm oil processing plant equipment. Medium palm oil processing plants with different processing volumes and equipment configurations have.

The cost to start and operate a palm oil refinery plant covers a lots of aspects. QIYI Machinery, as a reliable and professional manufacturer and supplier for palm oil processing machinery and palm oil refining equipment, will tell you how to calculate the cost of running a palm oil refinery plant. Cost of Setting Up A Crude Palm Oil Reinery Plant

How Much Does It Cost To Start A Palm Oil Refinery Plant

- Usage: Cooking Oil refine machine

- Type: Cooking oil refine machine

- Production Capacity: 100%

- Voltage: 220V/380V/440V

- Power(W): 5.5-22KW

- Dimension(L*W*H): 48m*12M*15M(30TPD)

- Weight: 30tons

- Raw Material: Sunflower Oil, Sesame Oil, Soybean Oil, Palm Oil, Coconut Oil,Peanut Oil, Castor Oil, etc

- Material: Stainless Steel SS304/316

- Application: Oil Production Line

- Function: Chemical oil refining and physical oil refining

- Application range: 10-1000tpd

- Advantage: Low consumption

- Power consumption: 17.5kwh-24kwh

- Steam consumption: 200-300kg per one ton crude oil

- Warranty: 12 Months

The cost of palm oil refinery plant is affected by many factors Actually, the exact cost of a palm oil refinery machine would vary from the different requirements and specific situations. Usually, the equipment cost for setting up a palm oil refinery plant ranges from $ 60,000.00 to $ 300,000.00.

How Much Does It Cost To Build A Medium-Sized Palm Oil Refinery

- Usage: All kinds of edible oil

- Type: Cooking Oil Refinery Machine

- Production Capacity: 100%

- Voltage: 380V OR REQUESTED

- Power(W): 300KW

- Dimension(L*W*H): 14X8X9M WORKSHOP

- Weight: 10T

- material: stainless steel or others

- Capacity: accordding to your requirement

- outstanding: low price, fast return

- Distillation range: 68-75℃

- Installation time: 30-45 days

- Delivery Time: 30 days

- Delivery port: Qingdao port

- Project: Turn key project

- Item: oil refining equipment

A Kenyan client successfully ordered an integrated edible oil pressing machine and 2tpd edible oil refinery machine from Henan Glory Company; What is a comprehensive guide to setting up the best cpo refinery plant? The 0.5TPD edible oil refinery machine have been successfully shipped from Henan Doing company to Uganda

India has around 550 units of edible oil refineries located in different States. The sources of edible oil manufacture are soyabean, groundnut, rapeseed, sunflower, safflower, cotton, sesame, coconut, palm, mustard, rice bran, watermelon, neem, mahua etc. The refined edible oil manufacturing units generate solid waste (spent earth) and wastewater

The cost of building a medium-sized palm oil refinery Business includes many aspects, among which the cost of palm oil refining equipment is only one factor. Toggle navigation [email protected] 0086 372 5965148

- How much does a palm oil processing plant cost in Indonesia?

- The first critical step in establishing a palm oil processing plant is to obtain suitable land, the cost of which varies according to location, soil quality and accessibility. In general, prime agricultural land suitable for palm oil cultivation may cost between US$2,000 and US$5,000 per hectare in Indonesia.

- Can you set up a palm oil milling plant in Indonesia?

- Setting up a palm oil milling plant in Indonesia can be a lucrative venture, considering the country's status as the largest palm oil producer in the world. However, embarking on such a palm oil processing project requires careful planning and a thorough understanding of the costs involved.

- How is palm oil biodiesel produced in Indonesia?

- The Conventional System depicts a typical production of palm oil biodiesel in Indonesia. The palm oil mill and the biodiesel plant in Indonesia are typically geographically separated, whereby the palm oil mill is closer to the plantation, and the biodiesel plant is located near a seaport to more easily serve the export market.

- How to refine crude palm oil?

- If the customer has his own palm oil mill, he can directly refine his crude palm oil. If the customer does not have a palm oil mill, he needs to buy crude palm oil from the market, which will result in the crude palm oil cost. This is mainly the cost of transporting crude palm oil to palm oil refinery.

- What is the difference between palm oil mill & biodiesel plant in Indonesia?

- The palm oil mill and the biodiesel plant in Indonesia are typically geographically separated, whereby the palm oil mill is closer to the plantation, and the biodiesel plant is located near a seaport to more easily serve the export market. The handling capacity of a palm oil mill in Indonesia is between 10 and 60 t-FFB/h .

- What is the capacity of palm oil processing plant?

- The capacity of the palm oil processing plant has to be taken into consideration. A palm oil refinery normally has a capacity of 50-1500T/D. Some of the refinery’s machines include a magnetic drum, cleaning sieves, crusher, flaker, and puffing machine.