Protein from rapeseed for food applications: Extraction Machine

- Usage: Cooking Oil Type: Rapeseed Oil Extraction MachineWeight: 3500 KGWarranty: One Year warranty against manufacturer defect.Oil type: Rapeseed Oilcomplete Warranty Service: Video technical supportAfter Warranty Service: Spare partsOn Site Warranty Service: Field maintenance and repair serviceProduct name: Oli Press MachineFunction: Making Edible OilApplication: Edible Oil ProductionKeyword: Mini Oil Expeller

Rapeseed meal, a primary by-product following rapeseed oil extraction, is rich in proteins (30?50 %), thus making it a promising plant protein with great economic value in the food industry (Albe-Slabi et al., 2022).

The temperature was adjusted to 102 °C and analyses were performed in triplicate. Determination of the oil content in rapeseed sediments by solvent extraction was performed in at least duplicate in a semiautomatic Soxtec apparatus (Tecator AB, H?gan?s, Sweden) using petroleum ether as a solvent. Oil content was expressed in a dry-matter

Extraction, Isolation of Bioactive Compounds and Therapeutic ..

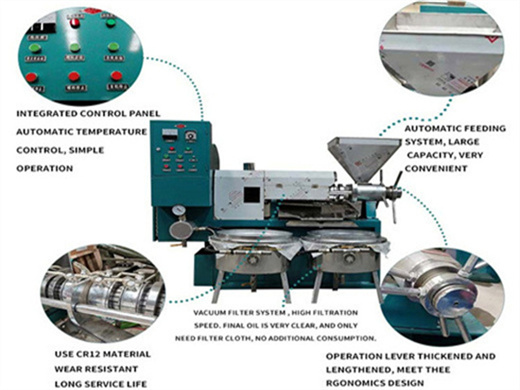

- Usage: oil press Voltage: 220V/110V, 220/110VWeight: 1400 kgCore Components: OtherOil type: Rapeseed OilModel: K28CPower: 750WProduction capacity: 50-700kg/hNet weight: 12.KgGross weight: 14KgProduct size: 50*18*30cmMaterial: Stainless steelControl method: Smart control + buttonKeyword: oil press machineCertification: CE

Molecules 2022, 27, 8824 2 of 24 material for the oil and fat industry, as well as the feed industry [6]. Gabriella Di Lena et al. provided data on the prospects for the use of rapeseed meal in

Rapeseed meal comes from the oilseed crushing industry, where it is the main co-product, accounting for around 55% of rapeseed mass. After oil extraction, the rapeseed meal contains around 35?40% proteins, plus carbohydrates (30?35%), crude fiber (10?15%), minerals (5?10%), and up to 10% secondary plant metabolites (von der Haal et al

Secondary structure of proteins on oil release in aqueous ..

- Usage: Vegetable Oilseed Type: Rapeseed Oil Extraction MachineProduction Capacity: 1tpdVoltage: 220V/380VDimension(L*W*H): 920*390*750mmWeight: 5000KGWarranty: 1 Year, 12 MonthsColor: greenMaterial: Carbon Steel Q235Product name: Screw Press Oil ExpellerMain shaft Speed: 8rpmKeyword: Large Cooking Oil Extraction Mill MachineryName: Large Animal Fat Oil Pressing MachineryFunction: Press Animal FatCertification: ISO

pollution, the demand for rapeseed oil green extraction processing is becoming increasingly urgent. Aqueous enzymatic extraction process, being applied to the oil extraction machine in the 1980s,[4] is considered to be the most appreciate process for replacing solvent extraction, which is safety, regulatory, environment friendly,[5?8] and provides

Rapeseed oil, often known as canola oil in North America, has become a staple in many kitchens around the world due to its versatility and health benefits. However, like any food product, it comes with its own set of pros and cons. This blog post will explore the benefits and drawbacks of using rapeseed oil, discuss the differences between cold-pressed and solvent-extracted varieties, and

Enzyme?assisted extraction of rapeseed oil with minimum water ..

- Usage: for oilseeds and Rapeseed oil

-

-

-

-

- Usage: Rapeseed OIL, All kinds of oil seeds Type: Rapeseed Oil Extraction MachineVoltage: 220VWeight: 2550 KG, 2550kgCore Components: Motor, Pump, EngineOil type: Rapeseed OilName: Rapeseed oil pressColor: blue/Silver/customizableMaterial: carton steelService: OEM and ODMPacking size: 2430mmx1460mmx1570mm

- How is rapeseed oil extracted?

- The extraction meal is desolventized by desorption and evaporation of hexane through direct and indirect steam injection. The oils are recovered by distillation of miscella, which allows evaporation of volatile solvents by vacuum steam stripping. Fig. 1. Conventional processing procedures for rapeseed oil extraction. Color online.

- Which solvent is used to extract rapeseed oil?

- It was also interesting to observe that p -cymene, d -limonene and isopropanol were the most effective solvents for oil extraction from the original rapeseed, and p -cymene, isopropanol and n -hexane were more selective. Table 1. Extracted rapeseed oil yields with various solvents. ISO 659-1988.

- What is rapeseed oil?

- Rapeseed oil third largest source of edible oil after soya bean oil and Palm Oil. Europe alone contributes six million tons to the world market. The seed is mechanically pressed or pressed to extract 50% to 75% of the Oil content in the seed before sending to solvent extraction to make the process more efficient.

- What are the optimal conditions for oil extraction from rapeseed?

- Above all, the optimal conditions for oil extraction from rapeseed and other seeds have been determined. n -Hexane, which has a relatively low boiling point (69 °C), is the commonly-used petroleum-based solvent for extraction of vegetable oils.

- Which sterols are found in extracted rapeseed oils?

- For sterols, no significant difference in composition and their relevant content was found among three extracted rapeseed oils ( Table 5 ). β-Sitosterol, campesterol and brassicasterol were identified as the three major sterols in extracted rapeseed oils, among which brassicasterol was used to determine the adulteration of other oils.

- What is the composition of fatty acids in solvent-extracted rapeseed oils?

- The composition of fatty acids in various solvent-extracted rapeseed oils. PUFAs: polyunsaturated fatty acids; MUFAs: monounsaturated fatty acids; SFAs: saturated fatty acids. Fig. 3. Chemical structure of free fatty acids in extracted oils. 3.3.3. Micronutrient analysis

subsequently impact the extraction of oil. Oil extraction Rapeseed oil was mechanically extracted using a pilot scale single screw press (BT Biopress Type 30, BT Maskinteknik ApS, Sindal, Denmark; Fig. 1). Prior to Figure 1 Set-up of the pilot-scale single screw press used for extrac-tion of oil from ?aked rapeseeds, showing the collection

Value of hydroalcoholic treatment of rapeseed Processing Machine

water content in the solvent enhances the extraction of non-lipid components but reduces the ef?ciency of oil extraction. Fauduet et al. (1995) studied the in?uence of ethanol-water mixtures on the extraction of glucosinolates from rapeseed meal and showed that increasing water content in the solvent