Supercritical carbon dioxide extraction of plant ..

- Usage: Edible Oil

- Capacity: 30-1000T/D

- Voltage: 380-660V, 380-460V

- Power (W): according to the capacity of the oil refining machine

- Dimension (L*W*H): according to the type of oil refining machine

- Weight : according to the capacity of the oil refining machine

- Material: Stainless steel and carbon steel

- Crude Oil humidity and volatile matter: 0.30%

- Electric consumption: depending on machine type

- Steam consumption: 280KG/T (0.8MPa)

- Export: USA, Europe, Japan and Korea in more than 60 countries. and regions

For example, adverse negative temperature effect was seen in milk thistle seed oil extraction. In this work, the authors have studied the oil extraction at various temperatures of 40, 60, and 80 °C by keeping the pressure and flow rate constant at 200 bar and 4 mL/min CO 2, respectively. The results showed that 40 °C was an optimized

The use of supercritical fluids, especially carbon dioxide, in the extraction of plant volatile components has increased during two last decades due to the expected advantages of the supercritical extraction process. Supercritical fluid extraction (SFE) is a rapid, selective and convenient method fo …

Supercritical fluid extraction in plant essential

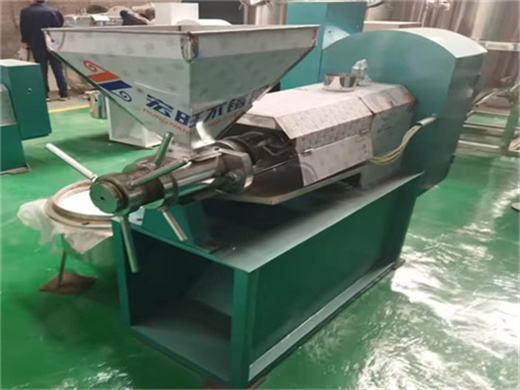

- usage: To Extract Oil From Various Oilseeds & Nuts.

- Capacity: high

- Voltage: 220V, 220V/OTHER

- Power (W): 7.5 kW

- Dimension (L*W*H): 1950x1300x1900

- Weight: 1100kg

- Application: oil press

- Material: Carbon steel

- Feature: cold and hot press

- Function: screw

- Capacity: 80- 600kg/ h

- Model: 6YL

- Price: Negotiable

They studied supercritical fluid extraction of volatile oil from J. communis Table 6 Percent yield and cumulative percent yield of the Laurel oil at different stages of the supercritical extraction (60-240 min), the overall run (SFE-T), and the hydrodistillation [ L. leaves using carbon dioxide was carried out under different conditions of

Supercritical fluid extraction using carbon dioxide (SFE-CO2) brings a convincing advance in the production of plant oils used in cosmetics, in fortified foods and dietary supplements, and in

Supercritical extraction technique of agarwood essential Oil Processing Machine

- Usage: Cooking Oil

- Capacity: 35-550kg/h hydraulic cooking oil press machine

- Voltage: 380V or local voltage

- Power (W): capacity

- Dimension (L*W*H): 900*850*1550mm

- Weight: 1000KG

- Certification: BV, ISO9001-2008,CE, ISO/CE/BV

- Item: Hydraulic cooking oil press machine

- Material: Stainless steel and steel stainless. Carbon steel

- Crude oil: After filtering, it can be used directly

- Capacity: Adjustable

- Patent: Yes

- Leaving time Delivery: 1 week

- Port: Qingdao

The common preparation methods of plant essential oil include water evaporation, pressing, freezing compression, immersion, solvent extraction, and supercritical fluid extraction (Yoswathana 2013; Dahham et al. 2015; Arumugham et al. 2021). There are no relevant reports on essential oil extraction with supercritical carbon dioxide.

Hey guys! I'm doing my final project of my masters degree. As the title says, the project requires an extraction of a essential oil from leaves with a supercritical fluid, CO2. The problem that I am having is justifying the amount of extraction vessels to use. Is there a optimum range of values to the diameter of such vessels?

SUPERCRITICAL FLUID EXTRACTION OF MEDICINAL PLANTS

- Usage: Cooking Oil

- Model number: cooking oil plant machinery

- Product extraction system: roasting system

- residual oil content: maximum 1%

- Packaging detail: 20ft, 40ft container

- solvent name: n-hexane

- raw material: rice bran, canola, sunflower seed, peanut, soybean, groundnut, etc.

- Capacoty: according to your requirements

- Package: container

Meireles EJEAFChe, 7 (8), 2008. [3254-3258] 3256 Table 1.- List of plant which antioxidant activity was measured by the coupled oxidation of linolenic acid

Supercritical Fluid Extraction of Plant Flavors and Fragrances

- usage: To Extract Oil From Various Oilseeds & Nuts.

- Certification: ISO, CE, BV

- Product type: centrifugal extractor machine

- Voltage: 220/380 Or other

- Residual oil in flour: ≤ 1%

- Capacity: 20-2000TPD

- Steam consumption: ≤ 280 KG/T (0.8 MPa)

- Energy consumption: ≤ 15KWh/T

- Raw material: Vegetable seed

- Material: Stainless steel and carbon steel

- Price: Negotiation

Abstract. Supercritical fluid extraction (SFE) of plant material with solvents like CO 2, propane, butane, or ethylene is a topic of growing interest.SFE allows the processing of plant material at low temperatures, hence limiting thermal degradation, and avoids the use of toxic solvents.

- Can Papua New Guinea still produce oil and gas?

- Papua New Guinea can still be successful in producing oil and gas well into the future, but it has to learn that it takes more than oil and gas reserves to create a viable and sustainable production industry. A review of its past successes should indicate what it needs to do.

- What is ExxonMobil doing in Papua New Guinea?

- ExxonMobil has had a presence in Papua New Guinea since the 1920s, and in addition to construction of the PNG LNG Project, the company has interests in fuels marketing and oil production. The PNG LNG Project is unlocking value from stranded gas resources in the Highlands of Papua New Guinea.

- Why did Chevron leave Papua New Guinea?

- With Kutubu oil production declining, Chevron departed the venture, selling its Papua New Guinea interests to Oil Search and over the course of several years, the schemes waxed and waned.

- How did Exxon & BP develop LNG in Papua New Guinea?

- With the foundations for the gas development defined by the revised gas regulatory and fiscal regime, Exxon and BP pursued their LNG development plans based on the large Hides gas field with notions of taking the gas to the Papua New Guinea north-coast and a deep water plant site at Madang.

- What was the Papua New Guinea gas project?

- The Papua New Guinea Gas Project, alias Papua New Guinea Gas to Queensland Project or Gas to Australia Project ended up with over 4,300 kilometres of trunk gas pipelines and lateral pipelines hanging off the Papua New Guinea gas sources.

- Why did Papua New Guinea explorers invest in oil?

- With diminishing oil production and the absence of new oil finds, Papua New Guinea’s explorers needed to capitalise on prior exploration investments that failed to find oil. Gas in the new century was no longer a hindrance and could be profitably developed even extending the life of the oil fields.