Castor Oil Manufacturing Process Flowchart How to Start a ..

- usage: To Extract Oil From Various Oilseeds & Nuts.

- Capacity: 5TPD-100TPD

- Voltage: manual

- Dimension (L*W*H): 270*260*350*60mm

- Weight: 3KG

- Main components: Motor, Motor

- Oil type: Cooking oil

- Product name: oil press machine manual

- Model: HDC

- Raw material: Sunflower/cocoa liquor/cooking, etc.

- Application: squeezing oil

- Power : manual

- Delivery: 7 business days

- Product capacity: 1-2kg. /h

- Package size: 42*8*32cm

- Certification: CE ISO

It connects a series of seed processing equipment to continuous oil extraction which can largely saving labor cost in production. The castor oil seeds undergoes many processes to produce castor oil. The following steps: seed cleaning, seed cooking, oil extraction, oil clarification, oil storage and filling.

We're professional castor oil extraction machine manufacturers and suppliers in China, specialized in providing high quality products. We warmly welcome you to wholesale bulk castor oil extraction machine from our factory. For price consultation, contact us.

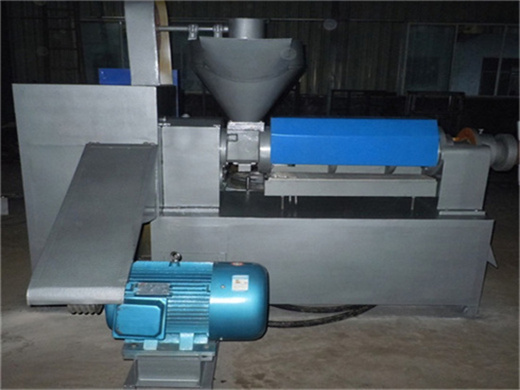

Castor Oil Extraction Machine

- Usage: Edible Oil

- Capacity: 1-100T/D

- Voltage: 380V/440v

- Power ( W): 20-50KW

- Dimension (L*W*H): 1900*1200*1600mm

- Weight: 500KG

- Main exporting countries: Asia, Africa, Latin America, Malaysia...

- Packaging: Glass container, Plastic container

- Grade: first grade refined oil

- : recycling machine of cooking oil

- oil content: 35%-48%

- fat: 40~60.7

- protein: 20~37.2

- phospholipid: 1.25 ~1.75

- saccharides: 5~15

- sunflower oil refining type: cooking oil recycling machine

The Castor Oil Extraction Machine is a standout piece in our Grain Processing Machinery collection.In China, sourcing reliable suppliers of grain processing machinery can be achieved through online B2B platforms, industry exhibitions, and verified supplier directories.

Crude Degummed Soyabean Oil (Ex-Mumbai) (Imported Oil) Rs./ MT 125600: Crude Palm Oil (5%)(Ex-Kandla) (Imported Oil) Rs./ MT 117500: Solvent Ext. Soyabean Oil (Indore) Rs./ MT 102000: Solvent Ext. R.B. Oil (RG-I) Rs./ MT 97000: Solvent Ext. R. B. Oil RG-II (Industrial) Rs./ MT 166000: Solvent Ext. Neem Oil: Rs./ MT 126500: Solvent Ext. Refined

Know about the Castor Oil Extraction Process Ambuja Solvex

- Usage: Cooking Oil

- Voltage: 380V

- Power (W): soybean oil processing line

- Dimension (L*W*H): soybean oil processing line soybean

- Weight: soybean oil processing line

- Product: soybean oil processing line

- Raw material: oilseeds

- Capacity: 5T to 2000T edible oil mill

- Oil residue: less than 1%

- Equipment material: stainless steel and carbon steel

- Manufacturing experience: 19 years of experience in edible oil fields

- Shelf life: several decades

- service: turnkey project and technology consulting

- materials raw materials: soybeans

But have you ever wondered what goes behind making Castor Oil from Castor Seeds? Let’s find out! The Complete Castor Oil Extraction process. Castor oil seed contains about 30%?50% oil (m/m) depending on its variety. Oil can be extracted from castor beans by mechanical pressing, solvent extraction, or a combination of pressing and extraction.

Castor Oil Manufacturers in Gujarat — At Appu Oil, we stand as a premier and are dedicated to providing top-tier high-quality Castor Oil Manufacturers in Gujarat and Oil Manufacturers in India. As a trusted name in the castor oil industry, we deliver premium products that meet stringent standards of excellence and innovation.

Castor Seed Oil Extraction Machine

- Usage: Cooking Oil

- Capacity: 20~2000T/D

- Voltage: 380v/50Hz

- Power (W) : above as per specifications

- Dimension(L*W*H): 1360*950*1170mm

- Weight: as per specifications

- Certification: ISO,SGS ,BV

- Function: cooking seed oil processing machine

- Model capacity: 10T/H,30T/H,45T/H,60T/H,80T/H,100T /H

- Suitable material: cooking material and similar oil

- Patented product: Yes

- Patent No.: ZL2007 20092291.7;

- Fully automatic: Yes

- Technology: cutting-edge technology in China

- Technology support: lifetime

- Warranty: one year

- After-sales service : Offering installation and debugging.

Find out what difference a quality fruit and veg supplier can make to your future business. We serve as a comprehensive source of agricultural & food manufacturers across China, and here is the list of Castor Seed Oil Extraction Machine factory, suppliers, manufacturers that match your Castor Seed Oil Extraction Machine product search.

20 Castor Oil Mill Machine, Capacity: 1-5 Ton/day

- Usage: Edible Oil

- Model number: GMS-QX1000

- Voltage: 380V, customized

- Power (W): 0.75kw

- Weight : 200kg, 200kg

- Dimension (L*W*H): 1900*835*880mm

- Material: 304 Stainless Steel

- Advantage: washing sweet potato

- Model: GMS-QX1000

- Application: carrot, potato, sweet potato, onion, etc.

- Replacement parts: brush

- Types of brush: hard and soft

Sri Ram Industries Offering 20 Castor Oil Mill Machine, Capacity: 1-5 Ton/day at 150000 in Dindigul, Tamil Nadu. Also find Oil Mills price list ID: 19848687997

- What is a castor seed oil production plant?

- The Castor Seed Oil Production Plant offered by GOYUM is robust, versatile, reliable and efficient. This Castor Seed Oil Production Plant is based on practically proven technology which is not only energy efficient & environment friendly, but also economical. We are leading manufacturer & exporter of Castor Seed Oil Mill Plant.

- How Castor oil is produced?

- It connects a series of seed processing equipment to continuous oil extraction which can largely saving labor cost in production. The castor oil seeds undergoes many processes to produce castor oil. The following steps: seed cleaning, seed cooking, oil extraction, oil clarification, oil storage and filling.

- What is castor oil extraction process?

- Castor bean is a kind of soft oilseeds with high oil content. Extraction of oil from castor seeds is similar to sesame, rapeseeds, cotton seeds, sunflower seeds and other seeds. Traditional screw pressing process can be adopted for industrial oil production. The following two common kinds of castor oil extraction process. 01. Twice pressing process

- How does a castor seed extraction machine work?

- Due to cooking, the oil droplets in the seeds come together and also the cell wall is broken, this results in improved oil yield and low power consumption. A continuous screw press is used to extract the oil. The castor seed passes through the machine where the screw shaft is rotated in the parallel direction and crushing the seeds.

- Who is mectech castor oil processing plant?

- Since its establishment in 1980, Mectech has delivered highly efficient and cost-effective Castor Oil Processing Plant to its clients. We are backed by strong leaders with rich experience in the extraction, refining, hydrogenation processes and saponification of castor oil.

- How is castor seed extracted?

- Castor seed contains about 30%–35% oil. The extraction process begins with the removal of the hull from the castor oil seeds. This can be accomplished with the help of a castor seed dehuller. After removing the hull from the seed, the seeds are cleaned in seed cleaner, the equipment has screens of various sizes that can remove inorganic impurities.