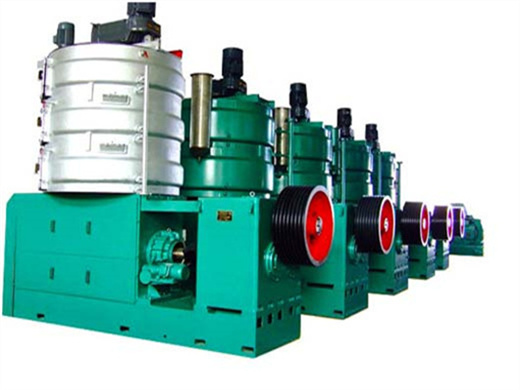

China Best Canola Oil Press Machine and Solvent Extraction

- Usage: Cooking Oil

- Capacity: 100-500 kg/h

- Weight: 0 KG

- Main components: Gearbox

- Full oil Service Warranty: Video technical support

- On-site warranty service: Field repair and maintenance service

- Raw material: Oilseeds

- Function: Manufacturing edible oil

- Application: Edible oil production

- Keyword 1: Pressing machine for oil production

Hydraulic canola oil press machines use hydraulic pressure to extract oil from canola seeds. They are more efficient than manual machines and suitable for medium-scale production. The machine applies pressure through a hydraulic system, crushing the seeds and extracting oil. Hydraulic machines offer higher oil yields and better control over the

The M70 Precision Cold Press oil extraction machine extracts 85% to 95% of the oil inside the vegetable matter, under “cold press” requirements. This uses mechanical oil extraction. By “mechanical oil extraction” we mean metal parts directly applying pressure to plant material and forcing the oil out; without any chemicals or high heat.

best palm oil screw press machine in kabwe

- usage: To Extract Oil From Various Oilseeds & Nuts.

- Capacity: 100% shell removing machine

- Voltage: 220 V/380 V/440 V

- Power (W): 10-50 kW

- Dimension (L*W*H): Depends on its capacity

- Weight: Depends on its capacity

- Raw material: peanuts and groundnuts

- Application: oil pressing

- Common capacity: 1-2000TPD

- Character: semi-automaticAfter-sales service: installation, debugging, training and service

- Advantage: energy saving / high oil yield

- Flow chat: cold pressing / hot pressing / pre-pressing

best palm oil screw press machine in kabwe . Type: Palm & Palm Kernel Oil Pressing Machine; Production Capacity: 30-450kg/h; Voltage: 3880V; Dimension(L*W*H): 1800*1300*1680

This is no exceptions to small canola oil pressing line. On the one hand, the small canola oil production generally employs screw oil press machine to obtain the oil. On the other hand, it also needs some of seeds processing auxiliary equipment to facilitate and enhance the oil pressing process. Canola Oil Production Process. Canola Oil

High Efficient Palm Kernel Oil Pressing Screw Machine at Low ..

- Usage: Cooking Oil

- Capacity: 100-500 kg per hour, small capacity

- Voltage: 220 V 380 V

- Dimension (L*W*H): 1400* 800*1000

- Weight: 170 KG

- Warranty: 1 year, 12 months

- Main components: Engine

- Oil type: Cooking oil

- Product name: Seeds Small capacity frying pan

- Raw material: Sunflower, beans, etc

- Function: Heating process

- Advantage: Energy saving

- Feature: Automatic machine

- Types of processing: By electricity

- Used for: Line oil production or food production line

- Package: Wooden box

Among our product range of oil mill machinery, YZS-150 oil press machine outstands out for its high oil yield, simple operation and stable performance. It is very suitable for bulk oil processing, and large and medium oil pressing and refining plants to process various oil-bearing seeds, such as sesame, peanut, cottonseed, coconut, palm kernel, corn germ, flaxseed, canola, sunflower seed and more.

We are an international manufacturer, supplier and exporter of oil pressing equipment and oil production lines. We can not only offer small scale screw oil presses for starters to easily enter into the profitable oil industry, but also boast strong strengths to undertake customized complete turnkey projects of edible oil mill plants. We have

best quality cheap coconut oil seed press machine in kabwe

- Usage: Cooking Oil

- Capacity: 5TPD

- Voltage: 220~240V,50-60Hz

- Dimension (L*W*H): 47.5*25*41cm

- Weight: 12kg

- Main components: Motor

- Oil type: Cooking oil

- Product name: oil making machine

- Control mode: Automatic

- Material: Stainless steel

- Suitable for: Home use

- Keep working: 12 hours

- Raw material input: 50-500 kg/h

- Feature: Easy to operate

- Advantage: Energy Saving

- Post-warranty service: online support

- Certification: CE

best quality cheap coconut oil seed press machine in kabwe . Production Capacity: 50kg/h-5000kg/h; Voltage: 220V/380V; Dimension(L*W*H): 850*520*800mm

Oilseed Presses Penn State Extension

- usage: To Extract Oil From Various Oilseeds & Nuts.

- Product type: Wood oil

- Processing type: Cold pressed

- Packaging: Bulk

- Purity (%): 100

- Volume (L): 10

- Grade: 1

- Certification: HALAL

- Product Name: 100% Pure Organic Natural Cooking Oil

- Refined Cooking Oil: CP8 Vegetable Oil

- Application: Industry

- USEFUL LIFE: 24 Months

Figure 2: Expeller Press (screw press) diagram Oil Production. Oilseed presses vary in size and the amount of oil expected varies between seed types. As a result, the capacity of an oil seed press is often given in the weight of seeds that can be processed per hour. Depending on the material processed, the expected oil output will vary greatly.

- What is screw oil press?

- Screw oil press is a compact-structured oil extrusion machine used for extracting edible oil from more than twenty kinds of oilseeds such as peanut, soybean, flaxseed, sunflower seed, rapeseed, etc. Different from integrated screw oil press machine, it is more suitable to large-scale cooking oil plants which produce various grades cooking oil.

- What is a commercial screw oil expeller machine?

- The commercial screw oil expeller machine has a compact and reasonable structure, which is mainly composed of the electric control cabinet, heating press section, adjustment section, transmission section, and vacuum oil filter section.

- What is the design model of screw oil press?

- The design model of the screw oil press can be small, medium, and large, which can meet all the needs of small oil mills, large oil mills, and edible oil processing enterprises.

- How screw oil press machine works?

- In the process of oil pressing in this screw oil press machine, friction between soil particles and between materials and parts produces heat, which constitutes the pressure and heat of the oil pressing process. This can destroy the material cell tissue, improve the oil yield.

- What is a screw oil press hopper?

- Screw oil press hopper is a specially structured reversed fastigiated container to feed oilseeds. In the middle are a screw device and a stirring rod. When you turn on the oil press, put the materials in the hopper, the screw device will turn round to help oil seeds go down the chamber smoothly. This structure avoids feed materials blocking.

- What is the production principle of oil expeller?

- The production principle of this oil expeller is very simple, mainly by using the mutual squeeze friction between the machines to break the raw material crops and generate heat to obtain the oil components therein.