Solvent And Chemical Batching Industrial Instruments

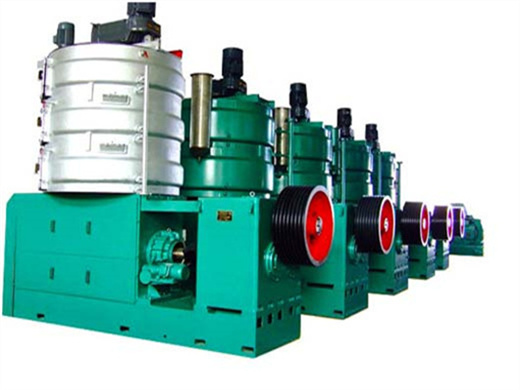

- Usage: Edible Oil

- Capacity: 100% seed oil making machine

- Voltage: 220V/380V/440V

- Power (W): 10-50kw

- Dimension (L*W*H): Depends on its capacity

- Weight: Depends on its capacity

- Raw material: All seeds

- Application: Oil pressing

- Common capacity: 1-2000TPD

- Character: semi-automaticAfter-sales service: installation, debugging, training and service

- Advantage: high oil yield

- Function: seed press/solvent extraction

Choice of pneumatically or electrically operated valves and weatherproof or flameproof batch controller make this an ideal solution for applications where automatic cut-off as well as high accuracy is desired. Solvent and chemical batching-Fluidyne. Fluidyne's dispensing and batching systems are flexible and highly dependable.

Gagan International supplies both, Batch type and Continuous Type, Solvent Extraction Plant. Brief Description about SOLVENT EXTRACTION PLANT: The separation of oils and fats from oil bearing material is carried out by pressing & solvent extraction.

SPECTEC Automatic Solvent Extraction Plant, Capacity: 50-2000 Tpd

- Usage: Cooking Oil

- Capacity: 10-3000L

- Voltage: 220V/380V

- Dimension (L*W*H): 1500*750*1800mm

- Weight: 500kg

- Main components: motor, pressure vessel, PLC, OTHERS

- Oil type: plant Cooking oil

- Raw material: seeds and oil plants

- Advantage: energy saving

- Color: Customer required

- Quality: Top level

- Function: extract material oil

- Oil rate: Refining over 98%

- MOQ: 1 set

- Shipping: Sea

- Price: Competitive

- Local service location: United States, India, Thailand

Spectec Techno Projects Private Limited Offering SPECTEC Automatic Solvent Extraction Plant, Capacity: 50-2000 Tpd at 10000000 in New Delhi, Delhi. Also find Solvent Extraction Plant price list ID: 16062085655

Solvent Extraction Gordon Ritcey SX Workshop 2007 Plant Design Considerations Presented by: Mark F. Vancas Plant Design Considerations Solvent Extraction Plant Design Considerations Design Criteria Production Rate PLS Grade PLS Flowrate Plant Design Considerations Mark F. Vancas Solvent Extraction Plant Design Considerations Design Criteria

Solvent Extraction Plants: Thiele Diagram & Theoretical ..

- Usage: Edible Oil

- Capacity: 200~2000T/D, 100%

- Voltage: 380v

- Power (W): 85kw

- Dimension (L*W*H): 1200*400*900mm3

- Certification: ISO9001,CE,BV

- Capacity: 1T to 500T

- Equipment material: stainless steel and carbon steel

- Raw material: Vegetable seed

- including: machines, installation, after-sales technical consulting

- operation: automatic and safe

- Warranty: 1 year

Table (i) lists some of the variables and questions to be answered which will affect design of the solvent extraction plant. Table (i) Solvent Extraction Data Needed for Flowsheet. the volume flow of leach liquor and copper tenor; volume flow of organic; the acidity/pH of the leach liquor; the raffinate level required; temperature of the closed

Industrial Solvent Extraction Plant Engineered Design, Electric Drive Type, Painted Finish Low Maintenance, Trouble Free Performance, Smooth Operation, Installation Services Available Kapurthala Engineering Works

Choosing the Right Solvent: Criteria for Optimal Plant Extracts

- Usage: Edible Oil

- Capacity: 20-300TPD

- Moisture of finished food: ≤ 13% (adjustable)

- Residual solvent in finished food: ≤300PPM (qualified detonated experiment)

- Steam consumption: ≤ 280KG/T (0.8MPa)

- Equipment material: Stainless steel

- Oil material: Peanut, soybean, Cooking oil cake, etc.

- Residual oil in flour: ≤ 1% (soy)

- Solvent consumption: ≤ 2Kg/T (solvent oil No.6)

- Crude oil moisture and volatile matter: ≤ 0.30%

- Power consumption: ≤ 15KWh/T

Explore the crucial role of solvents in extracting plant extracts, including the selection criteria, types of solvents, and extraction techniques. Delve into environmental and health considerations, case studies, and future trends in solvent selection for plant extraction processes. This comprehensive article provides insights into the significance of solvents in the extraction of plant-based

Solvent Extraction Plant for Making Vegetable Oil

- Usage: Cooking Oil

- Fully/semi-automatic

- Capacity: 1-500T/D

- Voltage: 220V/380V

- Power (W): 70-150kw

- Dimension (L*W*H): 5432*2636*2345

- Weight: 850 KG

- Dimension: standard

- Capacity: 10 ~2000T/D

- Main material: Carbon steel / stainless steel

- Color: as your request

- Quality control: X-ray detection

- Warranty period: one year

The solvent extraction plant is part of vegetable oil processing plant which is designed to extract oil directly from oilseed whose oil containing rate is less than 20%, such as soya bean after flaking or it extracts oils from pre-pressed or fully pressed cake of seeds with oil containing rate more than 20%, such as sunflower, peanuts, cottonseed, palm kernel, canola, copra, castor and variety

- What are the different types of solvents used in Indonesia?

- Indonesia boasts a diverse range of solvents, including but not limited to acetone, toluene, xylene, butanol, and ethyl acetate. These solvents are used in various applications such as cleaning, degreasing, thinning, and dissolving.

- What is Indonesia's solvent manufacturing industry?

- Indonesia’s solvent manufacturing industry has witnessed significant growth in recent years, fueled by the country’s abundant natural resources and favorable business environment. The industry plays a crucial role in supporting various sectors such as chemicals, pharmaceuticals, paints and coatings, adhesives, and more.

- Why is Indonesia a key player in the global solvents market?

- With its rich natural resources and booming manufacturing sector, Indonesia has emerged as a key player in the global solvents market. We will provide you with an in-depth overview of the leading manufacturers, highlighting their production capabilities, product range, and commitment to quality.

- How does a solvent extraction process work?

- Desolventising extracted material: When the extraction is complete, the solvent remaining in the material is removed using a combination of steam (direct and indirect) and vacuum. The solvent vapourises and is condensed in the solvent condensate. The mixture of solvent and water is separated in the solvent water separator tank by a gravity process.

- Why do you need a solvent extraction system?

- saves space in the laboratory.„SOXTHERM® extraction systems provide you with the ighest degree of laboratory safety. All processes are controlled automatically with con monitoring.”EC NOMICAL AND FAST SOLVENT RECYCLINGA process developed by C. Gerhardt means that solvents can be reclaimed almost comple ly and re used several times over

- What is a solvent recycling process?

- NOMICAL AND FAST SOLVENT RECYCLINGA process developed by C. Gerhardt means that solvents can be reclaimed almost comple ly and re used several times over REDUCED COOLING WATER CONSUMPTIONThe cooling water regulation make for low cooling water consumption. An external recircu