Flowchart process for biodiesel production from Peanut oil

- Usage: for cooking edible oil

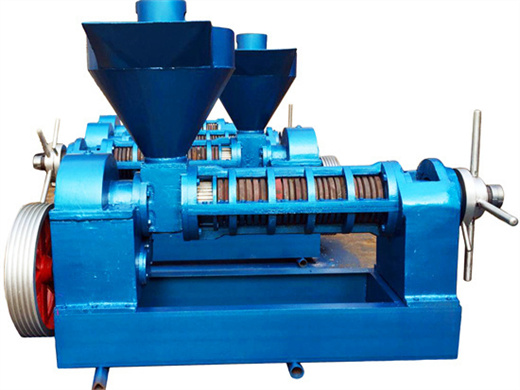

- Type: Oil Pressing Machine

- Production Capacity: 20-2000TPD

- Voltage: 380V

- Power(W): Standard

- Dimension(L*W*H): Standard

- Weight: Standard

- Note: 2 years spare parts for free

- Color: can be customized

- Capacity: 1-1000TPD

- Material: carbon steel & stainless steel

- Raw material: Peanut

- Advantage: easy use,energy saving,simple operation

- Function: get high quality cooking oil

- Feature: Full Automatic and Multifunction

- Package: Standard

Finally, as peanut is an oilseed with an oil content that can reach around 50% [28], peanut husks may contain oil or fractions of its respective fatty acids. In this context, Fig. 1 shows the

centrifugal sedimentation oil residue separator edible oil filter cooking oil filtration machine, You can get more details about centrifugal sedimentation oil residue separator edible oil filter cooking oil filtration machine from mobile site on Alibaba.com

Best Quality Control Automatic Peanut Cooking Peanut Oil Mill For Making Processing Peanut

- Usage: Peanut oil machine

- Type: soy beans oil press machine

- Production Capacity: 30-500T/D

- Voltage: 380V-415V

- Power(W): depend on the mode of the Peanut Oil Machine

- Dimension(L*W*H): depend on the mode of the Peanut Oil Machine

- Weight: depend on the mode of the Peanut Oil Machine

- item: Soy beans oil press machine

- production process: pretreatment,extraction,refining

- Raw material: Peanut

- Waste Bleaching Earth Oil Content: 25% to 35 %

- Electric Consumption: 28Kwh/T Oil

- Soften Water: 150Kg/T Oil

- Phosphoric Acid: 2~3 kg/T Oil

- Bleaching Earth Consumption: 80-500KG/T Oil

- Supplier Type: soy beans oil press machine

- Steel material: Stainless Or carbon steel

Steel drums for storing edible oil and sedimentation of impurities Weighing balance Semiautomatic bottle filling machine Molded polycarbonate bottle capping cum sealing machine If you want to go for pouch packing, you will need to have automatic pouch filling and sealing machine. Raw Material For Groundnut Oil Production

Application range of oil press machine. This screw oil press is designed for processing a variety of vegetable oilseeds and nuts. Examples include mustard seed, sunflower seed, rapeseed, peanut, castor seed, shea nut, coconut or copra seed, neem seed, cottonseed, jatropha seed, corn germ, flaxseed, Peanut kernel, Peanut seed, and more.

used machine sedimentation of cooking oil

- Usage: refined Peanut oil brazil

- Type: refined Peanut oil brazil

- Production Capacity: 100%refined Peanut oil brazil

- Voltage: 220V/380V/440V

- Power(W): 5.5-22KW

- Dimension(L*W*H): 48m*12M*15M(30TPD)

- Weight: 30tons

- Raw material: Peanut

- Material: Stainless Steel SS304/316

- Application: refined Peanut oil brazil

- Function: Chemical oil refining and physical oil refining

- Application range: 10-1000tpd

- Advantage: Low consumption

- Power consumption: 17.5kwh-24kwh

- Steam consumption: 200-300kg per one ton crude oil

How to purify cooking oil using sedimentation method? This study used the sedimentation method to purify used cooking oil. To aid the sedimentation method, activated carbon and clay soil was also used. Clay soil, also known as “heavy soil” was used in the sedimentation method since it absorbs and retains more components and substances. How […]

Based on our study at 71 river outlets along the Jakarta strait since 1915 to 1999 (see Fig. 2) [3], [10], the increasing of population and the environment degradation at the vicinity cities of Jakarta caused the sedimentation along the coastal area of Jakarta and gave a significant impact to JGSW, particularly the new deep seaport area that is

Functional Properties of Water Holding Capacity, Oil Processing Machine

- Usage: biodiesel plant for sale, Biodiesel production

- Type: small biodiesel plant

- Production Capacity: 100%

- Voltage: 220V/380V

- Power(W): Up to biodiesel plant

- Dimension(L*W*H): Up to biodiesel machine

- Weight: Up to biodiesel plant capacity

- Material: Carbon steel and stainless steel

- Place of Product name: Small biodiesel plant for sale

- Raw material: used cooking oil make biodiesel

For each sample, 20 mL of refined vegetable oil (sunflower oil, density = 0.89877 g. ml-1) were added and well mixed with the sample using a Vortex mixer at the highest speed, the samples were subsequently allowed to stand at room temperature (22 ± 2°C) for 30 min. Sample-oil mixture was centrifuged at 1200 g (3709 rpm) for 30 min (Model 3K

BEST Price Peanut Oil Extraction Machine for High Efficient

- Usage: Cooking Oil

- Production Capacity: 100-200kg/h

- Voltage: 380v

- Dimension(L*W*H): 880*440*770mm

- Weight: 260 KG

- Core Components: Motor, Engine

- Oil type: Peanut Oil

- Product name: oil fliter

- Application: edible oil

- Advantage: Energy Saving

- Function: Filter impurities and moisture

- Feature: High Oil Yield Efficiency

- Capacity: Large

- Used for: Edible Oil Making

- Color: Customer Required

- Application range: Food Edible Oil Produce

YZS series peanut oil extraction machine is passed with ISO9001:2015 and CE certifications. Apart from peanut, they are also suitable to extract oil out from a very wide range of raw materials, including Peanut kernel, cotton seeds, peanut, moringa seeds, tea seeds, niger seeds, rapeseed, mustard seeds and more.

- How is peanut oil made?

- After being mixed at a certain ratio, the crude oil is put into the sedimentation tank for sedimentation. After sedimentation, the crude oil is pumped into the frame filter for filtration, and the filtered product oil will be filled and packaged by a filling machine to form superfine fragrant peanut oil products (Fig. 3.9).

- What technology is used in peanut oil production?

- It starts by explaining the pretreatment technology and peanut pressing technology of high temperature and cold pressing peanut oil. It then discusses the peanut oil extraction technology, which includes leaching and separation technology. At the end of the chapter, it discusses the peanut oil production line and the relevant key equipment. 3.1.

- What is peanut oil extraction technology?

- Peanut Oil Extraction Technology The leaching method, also named the extraction method, is a method that uses certain organic solvents that can dissolve fat to spray and immerse the oil-bearing materials so as to eventually separate the fat from the materials.

- What is the development of peanut shelling mechanization in Nigeria?

- The development of peanut shelling mechanization in Nigeria lags far behind that of China, India, the United States, and Argentina, and most of them are still dehulled by hand, and many scholars have developed and improved a variety of mechanical peanut-shelling equipment (Figure 19). Figure 19.

- Should peanut shelling process adopt negative pressure air separation technology?

- The peanut shelling kernel shell separation process should adopt negative pressure air separation technology. China Oils Fats 1991, 51–52, 58. [Google Scholar]

- How to make peanut oil in China?

- Currently, there are two pressing methods: high-temperature pressing and cold pressing. More than 90% of oil production in China adopts the traditional technique of high-temperature pressing, and the peanut oil produced with this method has a strong fragrant flavor and is therefore greatly favored by consumers.