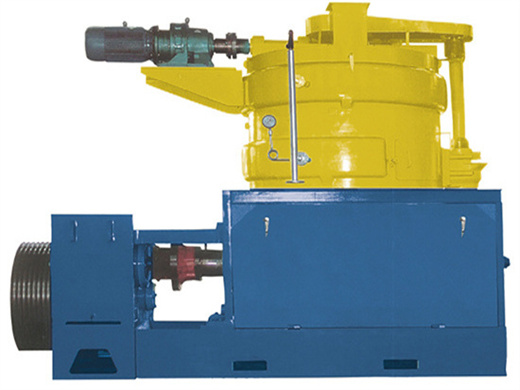

Hot Sale Mini Soybean Oil Making Machine Cold-pressed Oil Extraction Machine

- Usage: Cooking Oil

- Capacity: 50-300TPD

- Voltage: 380V/50HZ

- Power (W): according capacity

- Dimension (L*W*H): 1200*400*900mm3

- Certification: ISO CE BV

- Name: canola oil processing machine

- Application: extracted oil

- Residual oil in flour: less than 1%

- Energy consumption: not more than 15 KWh/T

- Solvent consumption: less than 2 kg/t

- Crude oil moisture and volatile matter: &le ; 0.30%

- Moisture of finished food: ≤ 13% (adjustable)

- Residual solvent in finished food: ≤300PPM (qualified detonated experiment)

- Steam consumption: ≤ 280 kg/t (0.8 MPa)

Tyre pyrolysis oil uses. Directly used as fuel oil? Tyre pyrolysis oil has a high heating value (10592.48 Kcal/kg), making it a direct replacement for fuel oil in industrial or boiler heating systems, such as those in cement plants, steel plants, glass plants, and other similar facilities.

The fuel oil can be used as industrial fuel materials for burning, or further refined to diesel or gasoline. The carbon black can be used for making construction bricks with clay or used as fuel. Both of the end products are in high demand and fetch good prices in the Gujarat market.

How do you make tyre oil? What is tyre oil manufacturing ..

- usage: To Extract Oil From Various Oilseeds & Nuts.

- Capacity: 100-3000TPD

- Voltage: 220V/380V/440V

- Power (W): 12.5 KW

- Dimension (L*W*H): 1100*2200*1400mm

- Weight: 1200 Tons

- Consumption of solvent: 1.5 kg/ton of raw material

- Color of the oil: pure yellow

- Method of obtaining the oil: pressing/extraction

- Form of heating: direct and direct. indirect steam

- Advantage: saving water resources

- Bleaching earth consumption: 5~50 kg/t of oil

- Steam consumption: very low

- discoloration function: to obtain a pleasant color

- deodorant function: eliminate bad smell

This obtained tyre oil from tyre recycling pyrolysis plant has a good price in the market. Some investors who want to do this project may wonder how is tyre oil made and what is tyre oil manufacturing process.

Waste oil distillation plant can convert waste engine oil, waste motor oil and waste tyre oil or waste plastic oil to diesel. This kind of diesel can be used directly for tractor, truck, ship and diesel based power generating machine etc. Oil recovery yield can reach 95%.

Waste Tyre to Oil Plant Recycling Waste Tires to Oil

- Usage: Edible Oil

- Automatic grade: Semi-automatic

- Capacity: 98%-100%

- Voltage: 220V /380V/440V

- Power (W): 15KW

- Dimension (L*W*H): 6000*700*5600mm

- Weight: 3000KG, 1 -30Tons

- Certification: ISO9001/CE/BV

- Raw material: Cooking

- Name: Cooking oil manufacturer

- Guarantee: One year

- Character: Oil processing line

- Advantage: Energy saving

- Common capacity (TPD): 1 -100THD

- Material: Stainless Steel

- Certificate: ISO9001/CE/BV

- Export market: Global

By using waste tyre to oil plant you can convert the waste tyres to oil. tyre to oil plant. The tire to oil process is a pyrolysis process, and the whole process needs high temperature. Before you start use the plant to convert waste tires to oil, some details you should bear in mind. 1. First, you should pull the steel wire out. 2.

Pyrolysis Oil. Tyre pyrolysis oil is mainly composed of hydrocarbon compounds and has a high energy density. The components of these liquids include aromatic hydrocarbons, aliphatic hydrocarbons, and other olefinic substances. Pyrolysis oil can serve as fuel or be further distilled to produce high-quality oil products.

Tyre pyrolysis oil as an alternative fuel: A review

- Usage: Edible Oil

- Capacity: 96%

- Voltage: 115V/380V (customizable)

- Dimension (L *W*H): 2200*1100*2000

- Weight: 1500 KG

- Main components: Motor

- Oil type: Cooking oil

- Name: Cooking oil pressed machine Cold Pressed Cooking Oil Cold Press

- Application: Edible Oil Production

- Function: High Oil Yield Efficiency

- Material: Stainless Steel 304

- Color: Customer Requirements

- Used for: Edible Oil Manufacturing

- Item: Cooking Oil Steam Distillation Equipment

The best way to tackle the waste tyre disposal problem is by the means of pyrolysis process. This process yields three principle products i.e. pyrolysis oil, carbon black and some non-condensable gases. The liquid fuel derived by the pyrolysis process of waste tyres has been tested as an alternative fuel for internal combustion engines [2], [3

Waste Tyre Pyrolysis Plant Kay Iron Works (Jorian) Pvt Ltd

- Usage: Edible Oil

- Capacity: 1-1000 TPD

- Voltage:220V/380V/415V

- Power (W): 1-30kw

- Dimension (L*W*H):1200*400*900mm3

- Certification:ISO9001

- Features:oil machine sesame

- Raw material: sesame, corn, soybeans, soybeans, sunflower seeds

- Guarantee: 1 year

- >Advantage: Energy savings and environmental protection environment

- Material: Stainless steel part

- Process section: pretreatment, pressing, extraction, refining

- Residual: Less than 2%

- Supplier strength: with 30 years of experience

- Machine color: according to customer needs

- Product name: sesame oil machine

We fabricate Waste Tyre Pyrolysis Plant using quality raw material. Our Waste Tyre Pyrolysis Plant is extensively used for the recycling of waste tyres, plastic, rubber and helps in producing fuel like oil, carbon black powder, steel, gas that are high in demand. Waste Tyre Pyrolysis Plant, supplied by us, ensures 100% recycle of waste tires

- How much does tyre pyrolysis oil cost?

- Fuel prices vary from region to region. The price of fuel in Americas is from 342 to 404 $/mt, in EMEA is from 326 to 349 $/mt, in Asia is from 355 to 379 $/mt. To avoid the impact of crude oil price fluctuations, more investors are optimistic about this kind of tyre pyrolysis oil.

- What is waste tyre pyrolysis oil?

- The oil is widely used as industrial fuel to substitute furnace oil or industrial diesel. It can be also called tire pyrolysis oil, crude TPO, tire pyrolytic oil, etc. In the waste tyre pyrolysis process, we can finally get waste tire pyrolysis oil and pyrolysis carbon black.

- What is tyre pyrolysis oil (TPO)?

- When you are using a pyrolysis oil plant to recycle waste tyres or waste rubber, you will get the valuable tyre pyrolysis oil and carbon black. Both of the end products are useful resources and can be applied in many industries. We will introduce the details on tyre pyrolysis oil in this page.

- Can tyre pyrolysis be used in PNG's OTML landfill?

- Other associated impacts at the OTML landfill where the waste tyres are stored include breeding of unwanted pests such as rats, snakes, and mosquitos. “The tyre pyrolysis technology is new in PNG and OTML is proud to trial it and provide a learning opportunity for mining and other industries in PNG,” Mr Min said.

- What is tyre pyrolysis carbon black used for?

- The carbon black from tyre pyrolysis can be used as the raw material to produce fortifiers, filler and colorant in rubber and plastic industry. It can be also refined into higher-quality carbon black like N330, N660, to earn a higher price in the market. Here is the test results of waste tyre oil.

- What can OTML do with pyrolysis oil?

- Manager Waste Management, Hendrick Min said, “Options are being investigated to reuse the by-products including use of pyrolysis oil as a fuel substitute in OTML’s Lime Kiln plant, char as soil additive in some of the revegetation and rehabilitation projects and steel wire as scrap metal recycling through existing waste metal recycling processes.”