An Extensive Resource on the Edible Oil Refining Process ..

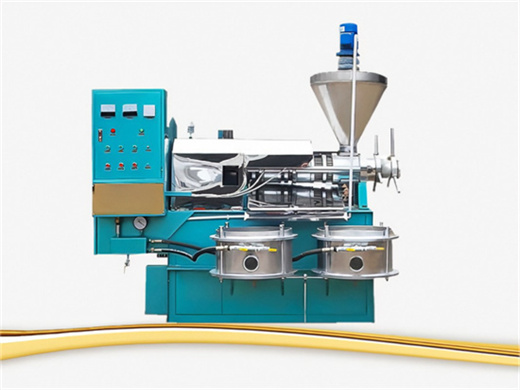

- Usage: Cooking Oil

- Capacity: 50-60 kg/h

- Voltage: 220V/380V

- Dimension (L*W*H)): 1450*870*1190 mm

- Weight: 320 KG

- Main components: Motor

- Oil type: Cooking oil

- Item: oil press machine screw

- Capacity: 50 -60 kg/h

- Raw material: nuts, seeds, beans, etc.

- Function: hot and cold oil press

- Advantage: Simple operation

- Material: Carbon steel

- Application: industrial oil press

- Post-warranty service: Video technical support

This blog delves into the various stages of the edible oil refining process, elucidating the importance of each step. 1. Degumming. The process of Degumming, or taking hydratable phospholipids out of crude oil, is the first step in refining. This is typically achieved by adding water or acid to the oil, which causes the phospholipids to

Parameters Checked in Edible Oil Laboratory. The edible oil laboratory can check several physical as well as chemical parameters of the oil. The properties checked are dependent on the instruments purchased. Fully fledged laboratory can perform almost all parameters but simple laboratory can check only below important parameters such as

edible oil refining GEA

- Usage: Edible Oil

- Capacity: 100%

- Voltage: 220V/380V

- Power (W) : 22kw

- Dimension (L*W*H): 48m*12M *15M(30TPD)

- Weight: 30 tons

- Raw material: Extruder machine soybean oil

- Application: Oil production line

- Function: Oil production

- Advantage: Energy saving

- br>Application range: 5tpd-500tpd

- Model: MS-100

- Features: energy saving

The crude oil is obtained by crushing the beans or seeds, the subsequent refining can be done either chemically or physically. GEA has extensive process line expertise for all the stages that contain centrifugal separators and decanters as well as for the production of high-quality by-products, i.e. lecithin and glycerine.

In recent years, we have witnessed the rise of edible oil industry installations concerning soyabean oil extraction and the further processing of soyabean oil.Demand has been notable in North American countries, including the USA, where soyabean is being processed to extract oil, its high protein content is being converted into soya protein concentrates and other products, and byproducts are

Edible Oil Refinery Plant PPT SlideShare

- Usage: Cooking Oil

- Capacity: 100% oil extraction plant

- Voltage: 220V/380V/440V

- Power (W): 22kw

- Dimension (L*W*H): 48m*12M*15M(30TPD)

- Weight: 30 tons

- Raw material: Carbon steel

- Color: according to customer's requirements

- Application: Oil production line

- Production period: 45-90 days

- Installation period: 60-90 days

- Supplier technology support: lifetime

- Material: food grade 304 stainless steel

?india’s first olive oil (zaitoon ) plant. 2010 ?india’s first hydrolysed lecithin plant.. 2011 ?india's first autoclave 25 bar with leak proof and maintenance free design for oleo chemical industries. 2012 ?india’s first fat splitting autoclave of 60 bar, 100% moc ss 316l. 2013 ?india’s first edible oil & fat processing plant

General overview of the chemical and physical refining process of crude oil. Physical refining of crude oils, therefore, overcomes the disadvantages of neutralization by sodium hydroxide . Indeed, this process, which is deemed to be eco-friendly, minimizes liquid effluents generation [29, 30].

Edible Oil Refinery Machinery Manufacturers, Suppliers ..

- usage: To Extract Oil From Various Oilseeds & Nuts.

- Capacity: 5TPD-100TPD

- Voltage: 380V/50HZ

- Dimension (L*W*H): depends on capacity

- Weight: 0.160 KG

- Main components: Motor

- Oil name: screw oil pressing machine

- Raw material: seeds

- Material: 304 stainless steel

- Function: Edible oil making

- Color: custom made

- Application: edible oil pressing

- Advantage 1: Energy saving

- Capacity: Large

- Advantage 2: with vacuum oil filter

CHEMPRO has served the edible oil industry since two decades, starting off as a small engineering company offering customized solutions for all aspects of edible oil refining. We through our unique and individualized approach offered cost effective upgrades to help our clients meet quality requirements or market change with substantial savings

Oil Refineries & Extraction Plants Manufacturers, Supplier ..

- Usage: Cooking Oil

- Capacity: 150 kg/hour

- Voltage: 220 V

- Dimension (L*W*H): 65*40*90 cm

- Weight: 55 KG

- Main components: Motor

- Oil type: Cooking oil

- Raw material: Vegetable seed

- Product name: Oil press machine

- Function: Edible oil manufacturing

- Application: Edible oil production

- Advantage: Simple operation

- Capacity: 20 kg/h Raw materials

- Color: Silver

- Used for: Edible oil manufacturing

- Range of application: Edible oil products for food

Brissun Technologies Pvt Ltd is a globally established engineering & manufacturing organization with expertise in Oil Refineries Plant, Edible oil mill refinery & extraction plants manufacturers, supplier & Exporter From India

- Who makes edible oil refining equipment & services?

- With a focus on quality and advanced technology, they provide comprehensive equipment and services for refining edible oils. The N&T management team is composed of experts with more than 40 years of expertise in the manufacturing of edible oil refinery machinery and equipment.

- Why should you choose N&T for your edible oil refinery?

- N&T is dedicated to providing high-quality edible oil refinery machines that require little to no maintenance with a wealth of manufacturing and processing expertise. Our edible oil refinery package is efficiently designed to maximise production in available working areas. Thus allow us to design compact equipment that uses low space.

- How to refine edible oil?

- The procedure we use to refine edible oil is as follows: Oil contains both hydratable and non-hydratable gums. Hydratable gums are removed by water degumming. N&T had developed the process for proper gum conditioning and caustic neutralisation, this process reduces the phosphorus content to the desired limits.

- How does Alfa Laval refine crude oil into edible oil?

- Refining crude oil into edible oil requires deep process knowledge—from degumming, neutralization and dewaxing through to bleaching, deodorizing and GE and 3-MCPD mitigation. Edible oil producers worldwide rely on Alfa Laval know-how to remove impurities and volatile components and optimize refining processes.

- What is vegetable oil refining?

- Refining is a process of bring vegetable oil by physical chemical changes to remove unwanted compounds and constituents so that to ensure the refined oil to optimal taste, aroma, stability and appearance. During the refining process the nutritional value of the edible oil will be un effected ensuring the stability, safety and yield.

- What is the process of oil refinement?

- The process of oil refinement ends with deodorization. It filters out odoriferous material, free fatty acids, and other undesirable components to create bland and stable oil. Our manufacture of edible oil refinery plants is continually evolving to meet plant specifications and deliver top-notch services.