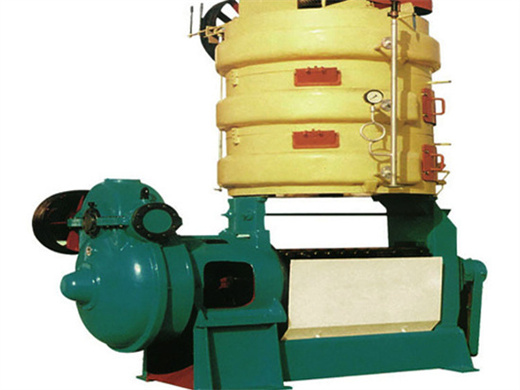

Flaxseed Oil Production Line Edible Oil Expeller Machinery

- Usage: Edible Oil

- Capacity: 80-600kg/h small Cooking processing machine

- Voltage: 380V

- Power (W): according to the capacity of the small Cooking processing machine

- Dimension (L*W*H): according to the capacity of the small Cooking processing machine

- Weight: according to the capacity of the small Cooking processing machine

- Certification: ISO, CE, CE/ISO

- Equipment: Small Cooking processing machine

- Capacity: for pressed oil

- Capacity: adjustable

- Screw speed: 30-40 r/min

- Transmission ratio: 15 /40x15/55=1

- Vacuum pump: Y90S-4-1.1Kw

- Production line: Yes

- Turnkey project: Yes

The Best Flaxseed Oil Processing Method Flaxseed oil contains an adequate amount of linolenic acid and the oil is usually extracted by low-temperature physical squeezing in the flaxseed oil production line. Because flaxseed oil has a balanced proportion of linolenic acid and linoleic acid, which is 1:4, and it is scientifically proven that when the […]

Modern machine from China is Professional production Edible oil filling machine,is used in Canola oil, corn oil, olive oil, peanut oil, sunflower seed oil,etc. Zhangjiagang Modern Machinery Co.,Ltd. More than 20 years technology & experience on bottle filling machine!

Flaxseed oil production line Flax Oil processing plant ..

- usage: To Extract Oil From Various Oilseeds & Nuts.

- Capacity: 10TPD

- Voltage: 220/380/440

- Dimension (L*W*H): Cooking oil screw press machine

- Weight: cooking oil screw press machine

- Warranty: 1 year, 12 months

- Product name: cooking oil making machine

- Raw material: sunflower

- Product: cooking edible oil

- Capacity: from 5T to 2000T

- Oil residue: less than 1%

- Function: obtain oil from oilseeds

- Equipment material: stainless steel and carbon steel

- Manufacturing experience: 40 years of experience

- Certification: CE&ISO&BV

Flaxseed oil production line Flax Oil processing plant castor oil extraction machine supplier https://www.zygroups.com/machine/Large-scale-complete-oil-proce

Rinsing can remove residual impurities left after the screening, making sesame cleaner. In addition, when rinsing, sesame seeds are soaked in the pool for 1 hour, which can make sesame seeds evenly saturated with moisture, and the protein denaturation can be improved thoroughly when the seeds are fried, At the same time, it can also prolong the time of seed frying to avoid the phenomenon of

Flaxseed Oil Press Machine & Flaxseed Oil Processing Steps

- Usage: Edible Oil

- Capacity: 100 kg/h

- Voltage: 380 V/440 V or required

- Dimension (L*W*H): 3740x1920x3843 mm

- Weight: 9000 kg

- Raw material: peanut, rapeseed, cotton seed

- Advantage: High oil yield

- Application: Production line of oil

- Function: Making edible oil

- Material: Stainless steel/carbon steel

- Color: Optional

Flaxseed Oil Press Machine. The flaxseed oil press machine provided by QIYI Machinery, professional oil processing machinery manufacturer in China, is certificated with ISO9001:2015 and CE. It stands out its counterparts for its high efficiency and cost effective performance. Flaxseed Oil Press Machine Structure

large scale palm oil milling plant refinery cooking palm oil boats strong pressing structure and automatic heating system for highest oil output.Different from traditional small oil screw press, Good quality 500 KG/H New type manual rapeseed mill spiral palm 6yl-130 oil press machine adds an automatic heater to increase the oil output rate by

Low-temperature Flaxseed/Linseed Oil Production Line

- usage: To Extract Oil From Various Oilseeds & Nuts.

- Capacity: 10T/D oil press

- Voltage: 380 V

- Dimension (length x width x height): 2720*1000*2700 mm

- Weight: 5600KG, 5600kg

- Key selling points: Multifunctional marketing machinery test report: provided

- Outgoing inspection video: provided

- Main components warranty: 1 year

- Main components: engine, others

- Maximum oil capacity: 9-12T/D

- New big oil press: 9-12T/D for pressing

- Main power: 18.5kw motor with reducer

- Oil residue: 6-7%

- Size: 2850*1850*3270mm

- Raw material: Oilseeds

- Function: Edible oil manufacturing

Low-temperature flaxseed oil press production line process. HongDe low-temperature flaxseed oil press production line process generally does not require chemical refining and only needs to go through hydration degumming, activated carbon deodorization, cooling, filtration, dewaxing, and other processes, to avoid alkali refining, active clay decolorization, high-temperature vacuum deodorization

Palm oil production line Palm oil mill, Our Oil Machinery

- Usage: Cooking Oil

- Capacity: 50T~150T/D

- Voltage: 220V/380V

- Power ( W): According to capacity

- Dimension (L*W*H): 1610x615x1260mm

- Weight: 1050 KG

- Certification: ISO9001

- Item: cooking oil extraction machine

- Mixed oil concentration: 18-25%

- Supply type: manufacturing

- After-sales service: Yes

- Crude oil index: 50-500ppm

- Solvent: hexane

- Extractor, Type: Rotocel Extractor, Drag chain extractor, loop type extractor

- Proportion of oil residue: 1%

Our Oil Machinery is a leading company in the field of palm oil pressing and palm kernel oil processing and equipment, we can provide completely set of 5-120tph palm oil production line. Our company offers a range of products and services for the palm oil extraction, palm kernel oil extraction, crude palm oil refining and complete palm oil

- Why is flaxseed oil pressed?

- The pressing production process keeps the most effective ingredients in flaxseed, such as polyunsaturated fatty acids, protein, dietary fiber, vitamins, trace elements and so on. The pressed oil is more suitable for a special supplement for human health.

- How is flaxseed oil processed?

- The Best Flaxseed Oil Processing Method Flaxseed oil contains an adequate amount of linolenic acid and the oil is usually extracted by low-temperature physical squeezing in the flaxseed oil production line.

- How to make flax seed oil?

- Therefore, when making flax seed oil, it is necessary to choose the physical pressing method at low temperature without any heating treatment. Low-temperature physical squeezing retains the activity of linolenic acid, and no additives in the whole process to maintain the natural quality of raw materials.

- Why is pressed flaxseed oil better than pressed wax?

- Second, the physical pressing temperature is lower than the melting point temperature of the wax, so that the pressed flaxseed oil is free from the “dewaxing” procedure and avoids the damage caused by the dewaxing process.

- Does flaxseed oil oxidize linolenic acid?

- Flaxseed oil can meet human health standards. However, linolenic acid is highly heat-sensitive and easily oxidized. When the critical temperature is exceeded, the activity of linolenic acid begins to be destroyed.