Turmeric Grinding Machine MILL POWER PVT. LTD

- Usage: Cooking Oil

- Capacity: 20tpd-100%

- Voltage: 220V/50HZ

- Dimension (L*W*H): 450*180*310

- Weight: 11kg

- Main components: Motor

- Oil name: oil presser

- Function: Edible oil manufacturing

- Raw material: sunflower, soybean, peanut, sesame, etc.

- Advantage: energy saving

- Material: 304 stainless steel

- Oil grade: food grade

- Capacity: 2-3 kg/H

- Model number: LTP205

Unlock the potential of efficient turmeric grinding with our specialized Turmeric Grinding Machine. Designed for precision, it ensures a fine grind every time, preserving the rich aroma and nutrients. Elevate your spice processing and achieve the perfect turmeric blend. Explore now!

MJ 4500G Mini Commercial Flour mill Machine Cocoa Soybean Coffee Pepper Sesame Turmeric Spices Home Powder Grinding Machine. Ready to Ship $111.76 130.24.

Haldi Grinding Machine

- Usage: Edible Oil

- Capacity: 5TPD

- Voltage: 220V/110V

- Dimension (L*W*H): 54.5*29*71cm

- Weight: 76 KG

- Main components: motor, gear

- Oil type: cooking oil

- Product name: Press machine multifunctional oil factory price oil extractor tool

- Function: oil extraction, oil mill

- Used for: cooking, sunflower

- Working capacity: 20 kg/h

- Material: 316 food grade stainless steel

- Juicing type: cold/hot press

- Machine color: Stainless steel

- Keep working: 12 hours

- Oil extraction: 90% oil yield

- Size: mini, small size

Model: 20 HP Turmeric Grinding Machine Without Motor Phase: Three Phase Capacity: 200 kg/hr Others: Condition : New Chamber size : 20" X 14" Automation Grade: Automatic Voltage: 220 V Purpose: Spice Grinding (Masala Grinding), Turmeric Grinding, Coriander Grinding, Chilli Grinding, Dry leaves Grinding etc. Power Consumption : 15 KW Motor rpm : 1440

Semi-automatic haldi grinding machine, impact pulverizer, de Automatic ginger & turmeric processing line- metal detector, Automatic haldi powder making machine, three phase, impact p Automatic turmeric powder processing plant, three phase, cap 7.5hp chilli grinding machine or haldi mirchi pisne ki machi

Turmeric Powder Making Machine

- Usage: Cooking Oil

- Capacity: 1tpd

- Voltage: 220v/380V

- Dimension(L*W*H): According to its capacity

- Weight : According to your capacity

- Certification: ISO9001: 2008;SGS;TUV

- Raw material: cooking

- After-sales service: technological support

- Features: High oil yield efficiency

- Advantage: Energy saving Low residue

- Character: Oil processing line

- Function: Oil pressing

- Quality: Stable quality

- Used for: Oil processing

Manufacturer of Turmeric & Ginger Processing Machinery Turmeric Powder Making Machine, Turmeric Processing plant, SS Grinding Machine and Oil Extraction System offered by Varaj Engineering, Pune, Maharashtra.

Different types of grinding machines are available depending on the fine or coarse powder requirement. For getting high-quality ground turmeric, the grinding temperature is kept very low by the mill operators. Once the grinding is complete, the powder is made to pass through a sieving machine and a magnet separating machine.

TURMERIC PROCESSING PPT SlideShare

- Usage: Cooking Oil

- Capacity: 1-2000TPD

- Voltage: 380V,440V

- Power (W): 11KW

- Dimension (L*W *H): 1360*950*1170mm

- Weight: 2000kg

- Capacity: 1-1000TPD

- Application: rice bran extract

- Function: oil extract line

- Operation mode: electric drive

- Machine name: cooking oil production/oil extract line

- Processing of residual oil into flour: ≤ 1%

- Solvent consumption: ≤ 3Kg/T

- Steam consumption: ≤ 3kg/t

- Energy consumption: ≤ 15KWh/T

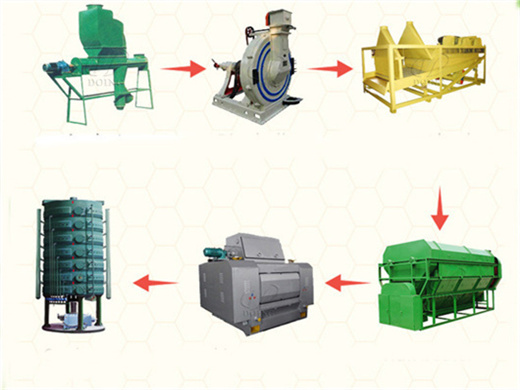

This document provides information about turmeric processing from various stages like washing, cooking, drying, polishing, grading, grinding and value addition processes like turmeric oil extraction and curcumin extraction. It includes details of machinery used in each process with specifications and capacities.

Haldi Grinding Machine Confider Industries

- Usage: Cooking Oil

- Capacity: 10T-3000T/D

- Voltage: 220V/380V/440V

- Power (W): 10-50kw

- Dimension (L*W*H): 1200*400*900mm3

- Weight: According to processing capacity

- Raw material : peanut/peanut

- Vapor pressure: ≥1.2MPa

- Volatile substance in crude oil: &le ;0.3%

- Steam consumption in refining : ≤280kg/ton of oil

- Oil residue in residual clay: ≤25% residual clay

- Solvent content in crude oil: ≤200ppm

- Oil residue in flour: <1%

- Feature: High oil yield efficiency

Confider Industries has created a haldi grinding machine that makes turmeric powder more quickly and efficiently than ever before. Call 99099-98977 to connect.

- What is techno wings turmeric grinding machine?

- Techno Wings turmeric grinding machine are mostly known as turmeric grinding plant, turmeric powder machine, turmeric grinder, turmeric processing plant supplier, mineral pulverising machines, pigment grinding system.

- What is the capacity of the turmeric grinding machine?

- The Techno Wings brand Turmeric grinding machine meets most capacity requirements. It lend themselves to a wide degree of adjustment with finesse of the finished products ranging from about 60 mesh to bulk passing through 300 mesh depending to a considerable extent on the particular materials being handled.

- How does a turmeric grinding machine work?

- The Turmeric grinding machine consists of an encased rotor carrying swing hammers, whizzer classifier for fineness regulation and pressure gradient creator mounted on a solid shaft. Raw material to be pulverized enters the crushing chamber through the hopper or the automatic rotary feeder.

- How to grind whole turmeric?

- Cleaned whole Turmeric can be collected as a product or proceed for grinding. Turmeric grinding with a capacity of more than 300 kg/hr is grounded in 2 stages: Stage 1, cleaned turmeric are grinded / crush into kibbles in the Universal Impact mill, collected in the hopper at the bottom of mill and fed to the 2 nd stage grinding.

- How is turmeric processed?

- Turmerics are pulverised in a grinder to convert them in powder form. Turmeric being solid by nature, it is taken to disintegrator and then pulverised. Then spices in powder form are passed through sieves to obtain uniform mesh size. Finally, packing is done in polythene bags and bags are sealed. Process loss is in the range of 5% to 7%.