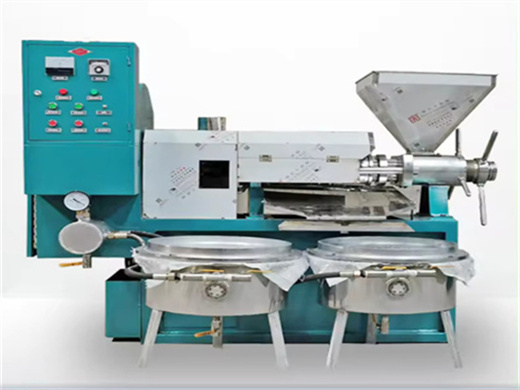

No Pollution Enterprises

- Usage: Cooking Oil

- Capacity: 1500 kg/h

- Voltage: 380v 50hz

- Dimension (L*W*H): 900 *1000*1650 mm

- Weight: 2000 KG

- Main components: Motor

- Oil type: Cooking oil

- Raw material: Oilseeds

- Function: Edible oil manufacturing

- Application: Food industry

- Advantage: Energy saving

- Feature: Cooking oil press machine

- Item: Cooking Oil Press Machine

- Quality: Excellent

- Material: 304 Stainless Steel

- Used for: Edible Oil Making

- Types of processing: Edible oil pressing line

He has led and or participated in more than 100 pollution prevention assessments and audits at large industrial complexes such as coke chemical plants, oil refineries, steel mills, copper smelting and recycling plants, wood preserving plants, machine building plants, armaments manufacturing facilities, pulp and paper mills, tanning operations

No Pollution Enterprises has experience in providing risk management evaluations, analyses of emissions inventories, and reconstructed emissions for all of the following industries and sectors: large industrial complexes such as coke chemical plants; oil refineries; steel mills; copper smelting and recycling plants; wood preserving plants

brand green tech used motor oil recycling machine in durban

- Usage: Cooking Oil

- Capacity: 10--500TPD

- Voltage: 220V, 380V

- Power (W): 11 KW

- Dimension (L*W*H): According to its capacity

- Weight: 1000kg

- Supplier Origin: Henan, China

- Texture: Stainless steel or carbon steel

- Oil rate: High oil rate

- Product level: Turn key project

- Raw material: canola seeds, rice bran, corn germ, soybeans, cotton seeds

- Consumption: low consumption

- Operation: fully automatic

- Desolventizer Item: oil pressing machine

Used Electric Motor Recycling Machines for sale. SSI. Electric Motor Recycling Machine Double Platform 240/460V. used. Seller going out of business (3) set of Double platform machines (1) 240V (2) 460V 1 platform is for cracking cast and splitting stators 1 platform is for extracting copper Processes up to a 13″ diameter stator T

If you are interested in invest in chilli seed oil processing business, subcritical oil extraction machine is what you need. It is a kind of cold oil extraction technology, best choice for extracting oil from seeds of chili or pepper. (Related Post: Spice Oleoresin Extraction) Subcritical Chilli Seed Oil Extraction Machine

Citrus Essential Oil Extracting Machine Biodiesel Machine

- Usage: Cooking Oil

- Capacity: 1tpd-30tpd

- Voltage: Design according to customer demand

- Power ( W): 11 KW

- Dimension(L*W*H) : 4935*1523*2664

- Weight: Standard

- Production Material: Stainless steel or carbon steel

- Raw material: Suitable for oil Cooking seeds and others

- Export markets: Europe, Southeast Asia, Africa, etc

- Working principle : Mechanical extrusion

- Warranty period: One year

- Used for: Cooking oil manufacturers

Citrus Essential Oil Extracting Machine. Citrus essential oil extractor is designed with ALFA technology and adapts to the characteristics of various citrus. After the citrus fruits are cleaned, they are fed into the oil extraction machine by feed scraper, where the high-speed spine needle roller prick and orange skins and extract the oil.

Pilotech YC-200 plant extraction machine consists of extraction tank, concentration tank, vacuum pump, oil-water separator, foam breaker and condenser. The extraction tank and the concentration tank feature a three-layer jacket structure. Pilotech plant extraction machine is equipped with the oil-water separator.

Oil Extraction Process Explained: 7 Steps You Need to Know

- usage: To Extract Oil From Various Oilseeds & Nuts.

- Model number: extraction plant

- Extraction Crude oil moisture and volatile matter: 0.30%

- Finished flour moisture: 10-13% (adjustable)

- Steam consumption: 280 kg/t (0.8 MPa)

- Residual oil in flour: 1% (cotton seeds)

- Solvent consumption: 3Kg/T (6 #solvent oil)

- Residual solvent in finished flour: 300PPM (qualified detonated experiment)

- Function: solvent extraction of Cooking fiber

- Minimum order quantity: 1 set/sets

Various oil extraction methods and oil extraction techniques ensure the maximum recovery of oil, making it a vital component of the global energy supply. The continuous advancement in petroleum extraction technologies promises even greater efficiency and sustainability in the future.

Best Oil Draining Solution Pneumatic Oil Extractor AUTOOL

- Usage: Edible Oil

- Capacity: 100% oil press machine

- Voltage: 220V/380V/440V

- Power (W): 5.5 ~ 18.5 KW

- Dimension (L*W* H): 1950*1300*1900, according to capacity

- Weight: 950KG

- Certification: ISO9001/CE/BV

- Raw material: Vegetable Seed

- used for: oil extraction systems

- Application: Oil pressing

- Common capacity: 80-600kg/h

- Warranty: one year

- Character: oil pressing machine

- discoloration time: 15-20 min

- Humidity: 3%

- residual oil in cake: 2%

With an all-in-one design, no tool searching is needed during replacement. The AUTOOL Pneumatic Oil Extractor uses patented vacuum technology to pump oil automatically into the measuring cup or barrel, eliminating manual oil draining. 2.What are the advantages of Pneumatic Oil Extractor? Traditional gravity oil drainage requires an oil drain