Oil Recovery Centrifuge Machine Engine Oil Centrifuge ..

- Usage: Cooking Oil

- Capacity: 1-2000TPD

- Voltage: 380V

- Power (W) : automatic oil machine

- Dimension (L*W*H): automatic oil machine

- Weight: automatic oil machine

- Raw material: mustard

- Product: oil

- Solvent name: n-hexane

- Capacity: 1-3000TPD automatic oil machine

- Oil content: 18 -22%

- Oil residue: less than 1%

- Function: automatic oil machine

- Manufacturing experience: 40 years

- Equipment material: stainless steel and carbon steel

Manufacturer of Oil Recovery Centrifuge Machine Engine Oil Centrifuge, Automatic Oil Recovery Centrifuge, Manual Oil Recovery Centrifuge Machine offered by Oilmax Systems Private Limited, Pune, Maharashtra.

Higher oil recovery is attained by selecting a microbe-nutrient combination having a higher ratio of value between biosurfactant yield and microbial yield parameters, as they combinedly influence the oil recovery by 27%. Neural Network is the best ML model for MEOR application to predict oil recovery (R 2 ≈0.99).

Application of machine learning techniques for selecting the ..

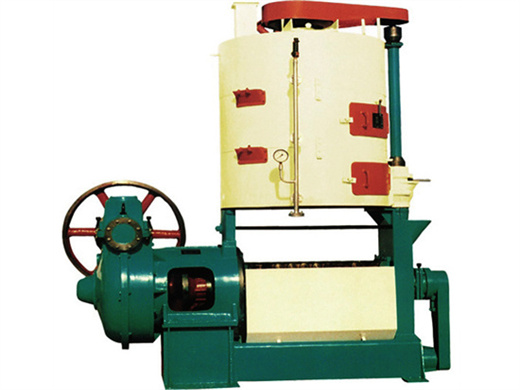

- Usage: Cooking Oil

- Capacity: 1-100T/D

- Voltage: 380V/440v

- Power (W) : 20-50KW

- Dimension (L*W*H): 1900*1200*1600mm

- Weight: 500KG

- Main export countries: Asia, Africa , Latin America, Malaysia...

- Packaging: Glass container, Plastic container

- Grade: first grade

- refined oil: 1st grade edible oil

- oil content: 35%-48%

- fat: 40~60.7

- protein: 20~37.2

- phospholipid: 1.25~1.75

- saccharides: 5~15

- Refinery type: small scale vegetable seed oil refinery

Tertiary recovery or Enhanced Oil Recovery (EOR) methods are some sophisticated procedures which target the immobile parts of hydrocarbons remaining in the reservoir (Green and Willhite, 1998). Owing to the considerable researches on EOR methods in last decades, today there are more than twenty types of different EOR methods ( Taber et al., 1997 ).

Carbon dioxide enhanced oil recovery (CO 2-EOR) projects not only extract residual oil but also sequestrate CO 2 in the depleted reservoirs. This study develops a machine-learning-based workflow to co-optimize the hydrocarbon recovery, CO 2 sequestration volume and project net present value (NPV) simultaneously.

Machine-learning-based prediction of oil recovery factor

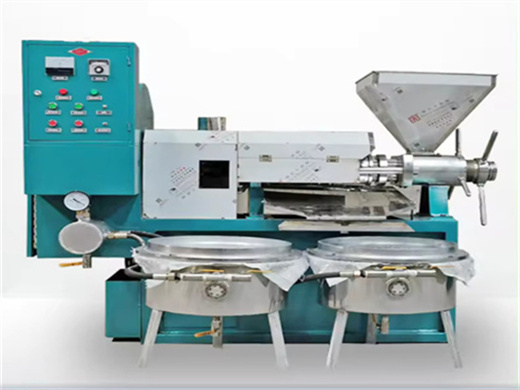

- usage: To Extract Oil From Various Oilseeds & Nuts.

- Model number: TP-70

- Purpose: cooking and others

- Description: high purity

- Material: stainless steel

- color: bright fresh

- smell: original cooking oil flavor

- original: china

- technology: 2016advantage technology

- certificates: CE/BV/ISO9001

- happy oil: 21%

Prediction oil recovery of experimental nanofluid injection: 108: Size, oil density, viscosity, porosity, permeability, salinity, nanoparticles concentration [58] LR, MLP, SVM CMIS: Prediction oil recovery of experimental low salinity flooding: 1316: Operational parameters, rock properties, oil properties, brine properties, connate water

Keywords: Classification, Machine learning, Oil recovery factor, Extreme gradient boost 1. Introduction Accurate estimation of ultimate recovery factor (RF) has broad applications to oil and gas exploration. The RF is an indicator of how feasible a reservoir would economically be produced during its lifetime (Beaumont et al., 2019).

OPERATING INSTRUCTIONS MODEL# 69360, 69365

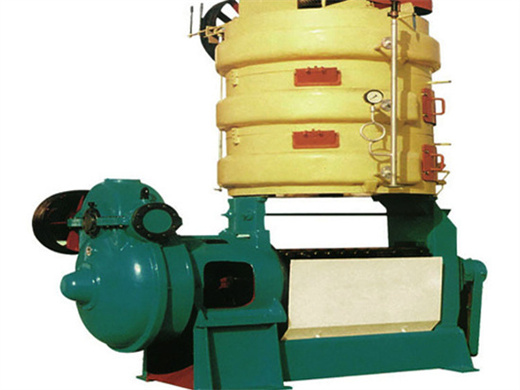

- Usage: Cooking Oil

- Capacity: 100TPD, 1t/24h

- Voltage: 220V/380V

- Dimension (L*W*H): 1128*820*1600mm

- Weight: 1700 KG

- Main components: Motor, oil extraction machine

- Oil advantage: energy saving

- Material: steel stainless and alloy steel

- Color: silver

- Features: high oil yield efficiency

- Raw material: vegetable seeds

- Capacity: 200 kg/h

- Keyword 3: Cooking oil extraction machine

B. Connect yellow hose to recovery machine outlet. Valve end of hose is connected to recovery tank. If recovery machine shuts off due to full tank, close valve in yellow hose, shut off machine, replace and connect empty recovery tank to yellow hose and restart Recovery Machine. If Recovery Machine does not start refer to Steps 8 and 9. 1.

Using Machine Learning Methods Recovery Prediction

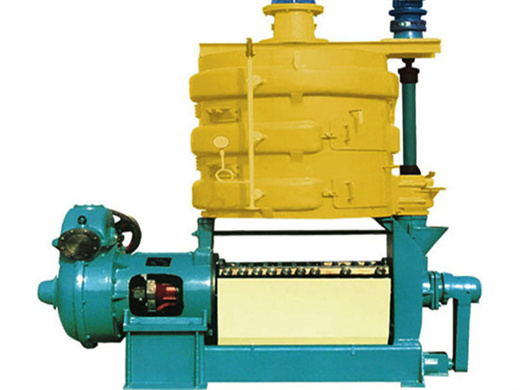

- Usage: Cooking Oil

- Main components: Q345R steel plate

- Structure: boiler inner coil

- Pressure: 1.0 mpa-2.0 mpa

- Steam production: 120kw/h--14000kw/h

- Fuel: Biomass

- Output: HOT WATER

- Dimension (L*W *H): accept customization

- Weight: accept customization

- Product name: Biomass heat conductive oil boiler

- Material: Q345R steel plate

- Terminal efficiency:>98%

- Nominal evaporation: 120kw/h--14000kw/ h

- Working pressure: 1.0mpa-2.0mpa

- Boiler structure: Boiler inner coil

- Applicable fuel: Biomass

- driving oil: 340℃

- normal steam:>350℃

- Packing size: 5600*2250*2750

Summary In recent years, machine learning methods have been widely used in various fields of science for big data processing. The application of machine learning in the oil industry is also actively expanding. To solve oil recovery problems, it is necessary to use geological models of reservoir fields. With increasing of the reservoir model complexity (size), the computing time also increases