Know about the Castor Oil Extraction Process Ambuja Solvex

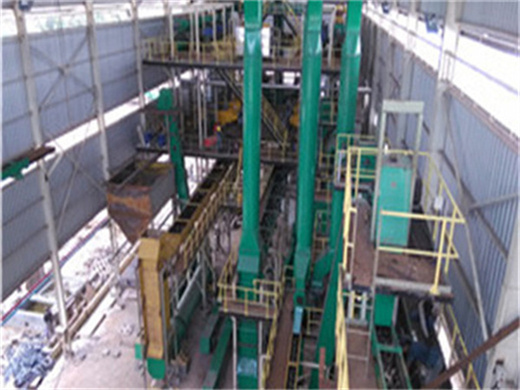

- Usage: Edible Oil

- Capacity: 150TPD(24hrs)

- Voltage: according to capacity

- Power (W) : depends on capacity

- Dimension (L*W*H): 120*100*16m

- Weight: according to capacity

- Certification: ISO9001

- Moisture of finished food: <13% (adjustable)

- Overseas installation: Yes

- Residual oil in flour: <1%

- Crude oil moisture and volatile matter: <0.3%

- Phosphoric acid: 2~3 kg/t oil Oil content of Residual bleaching earth: 25% to 35%

But have you ever wondered what goes behind making Castor Oil from Castor Seeds? Let’s find out! The Complete Castor Oil Extraction process. Castor oil seed contains about 30%?50% oil (m/m) depending on its variety. Oil can be extracted from castor beans by mechanical pressing, solvent extraction, or a combination of pressing and extraction.

Castor oil can be extracted from the castor beans through various methods, including pressing and solvent extraction. Pressing involves applying pressure to the beans to release the oil, while solvent extraction uses solvents to dissolve the oil from the beans.

Unlocking the Secrets of Castor Oil Extraction: Step-by-Step ..

- usage: To Extract Oil From Various Oilseeds & Nuts.

- Capacity: 10-2000T/D

- Voltage: Up to specification

- Power ( W): 7.5 kW

- Dimension (L*W*H): 2050*1350*2000Weight: 1000kg

- Material: Carbon Steel

- Operation : Easy to operate

- Raw material: Soybean

- Color: According to customer requirement

- Application: Oil Production Line

- Quality: Top level

- Advantage: High oil yield

Castor oil production: Castor seeds generally contain 30 to 50% oil, so in order to extract as much oil as possible, mechanical pressing (also known as pre-pressing) with an oil expeller must usually be followed by solvent extraction. Castor seeds need to go through a number of preparation stages in order to produce castor oil with a high

castor oil/polyether mixture was reacted with toluene diisocyanate (Ogunniyi et al., 1996). Sebacic acid is manufactured by heating castor oil to high temperatures (about 250 °C) with alkali. This treatment results in saponification of the castor oil to ricinoleic acid that is then cleaved to give capryl alcohol (2-octanol) and sebacic acid

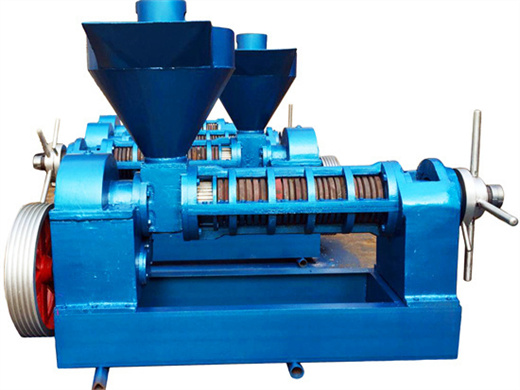

Advanced Castor Oil Extraction & Refining Machine

- Usage: Edible Oil

- Capacity: 50-100 kg/h

- Voltage: 380 V

- Dimension (L*W*H): 920*480*760 mm

- Weight: 330 KG

- Main components: Motor

- Oil name: Vegetable oil extraction machines

- Capacity: 80 -130kg/h

- Keyword 1: Black seed oil pressing machine

- Capacity: 3-5 tons/day

- color: according to your preference

- Squeezer diameter: black seed oil pressing machine

- Impurity: less than 0.2%

- residual oil rate: black seed oil pressing machine black seed

Step 2: Solvent Extraction for Castor Oil: Castor Oil Cake → Solvent Extraction → Mixed Oil → Settling → Evaporation → Vapor Extraction → Crude Castor Oil; After the harvest of the seeds, they are left to dry. This allows the seed hull to split for the release of the seeds. Castor oil extraction starts with the dehulling of the seeds.

Chemical Properties of the Crude and Refined Castor Oil Property Crude Castor Oil Refined Castor Oil Acid Value [mg NaOH/g of Oil] 1.148 0.869 Saponification Value [mg KOH/g of Oil] 185.83 181.55 Iodine Value [g I2 /100g of Oil] 87.72 84.8 Table 4.

Production of Detergent from Castor Oil

- Usage: Cooking Oil

- Capacity: 10-100TPD cooking oil plant

- Voltage: 380V

- Power (W): 3KW-15KW

- Dimension (L*W) *H): 450*230*350mm

- Weight: 700kg

- Material: Stainless steel, non-carbon steel

- Raw material: Corn germ, peanut, cotton seeds, sunflower seeds, etc

- Processing Capacity: Oil production line kitchen 10-500TPD

Leonardo Electronic Journal of Practices and Technologies Issue 9, July-December 2006 ISSN 1583-1078 p. 153-160 Production of Detergent from Castor Oil Abubakar Garba ISAH Department of Chemical Engineering, Federal University of Technology, P.M.B. 65, Minna, Nigeria, [email protected] Abstract This research work was carried out with the objective of extraction of oil from castor seeds and its

Castor Oil Extraction: Methods and Impacts Request PDF

- Usage: Cooking Oil

- Voltage: 220V/380V/440V

- Power (W): 7.5kw

- Dimension (L*W*H): 2000x1400x1850mm

- Weight: 1200kg

- Application: oil extraction machine

- Raw material: Vegetable seed

- Material: 304 stainless steel

- Function: Oil Extraction Machine

- Character: Oil Extraction Machine

- Feature: Automatic Feeding

- Quality: Top Level

- Wearing parts: Squeezable spiral

The industrial process of castor oil extraction exposes the material to chemical, thermal, and mechanical treatments that influence the properties of the proteins in the meal. This study tested