How many types of refining method are there in edible Oil Processing Machine

- Usage: Edible Oil

- Capacity: 20-250 KG/h

- Voltage: 220 V

- Dimension (L*W*H): 650*670*1125 mm

- Weight: 120 KG

- Main components: Motor

- Material: Stainless steel oil pressing machine

- Function: Oil pressing

- Power: 3650w

- Processing types: Fully automatic machine

- Advantage: Energy-saving method with low waste

- to press: Screw Press

- Press Suitable for: Oil Workshop

- Final product: Cooking Oil Production

Compared with batch type, the deodorization process of semi-continuous edible oil refinery plant is continuous. And the whole process of full-continuous edible oil refinery plant is continuous. Next, you also need to choose suitable edible oil refining method according to crude oil kind and finished oil requirement, capacity, and budget.

It is available for refining palm oil, palm kernel oil, corn germ oil, peanut oil, soybean oil, sunflower seed oil, rapeseed oil, rice bran oil, coconut oil, etc. Contact Us. Please kindly leave your requirements in detail or contact us via +86 13526627860. Our professional project manager will contact you within 24 hours.

The crucial role of refining units in edible oil extraction

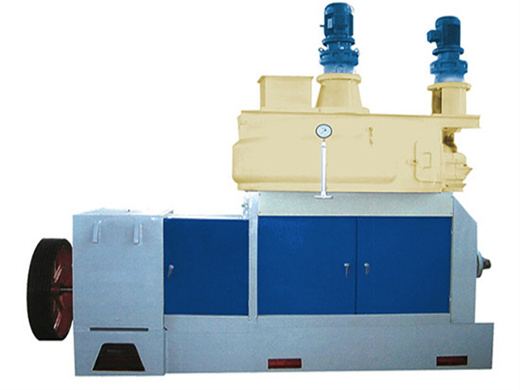

- Usage: Edible Oil

- Capacity: 10~2000T/D

- Voltage: up to specification

- Power ( W): 7.5 kW

- Dimension (L*W*H): 2050*1350*2000Weight: 1000kg

- Function: oil making oil machine

- Capacity model: 10T/D----1000T/D (daily processing capacity)

- Suitable material: rice bran

- Patented product: Yes

- Patent No.: ISO9001

- Fully automatic: Yes

- Technology: cutting-edge technology in China

- Technology support: lifetime

- Warranty: one year

- After-sales service: installation and debugging offer

The refining units play a crucial role in the edible oil extraction process. Its main function is to deeply process the crude or semi-refined oil to remove impurities, undesirable pigments, and odor substances,improving the purity, taste, and quality of t

Steam deodorized tower in continuous edible oil refinery plant. Some manufacturer’s edible oil refinery machine is very cheap. That is because they take rid of deodorization part so as to ensure more profit. See the following edible oil refining process flow chart they send to customers. Other manufacturer’s edible oil refining process flow

semi-continuous refining process?_Tech

- Usage: Edible Oil

- Capacity: 1t/day-1t/hour

- Voltage: 380V/220V

- Dimension (L*W*H)): 750*800* 1200mm

- Weight: 520KG

- Main components: Motor

- Oil type: Cooking oil

- Name: oil pressed machine cold

- Function: cold pressing of oil

- Raw material: Sunflower, cocoa, hemp seeds, cooking, etc.

- Material: 304 Stainless Steel

- Delivery time: 10 business days

- Package: Wooden Box Package

- Capacity for crude oil material: 20-30kg/h

- Press type: Hydraulic pressure

- Post-warranty service: video technical support, online support, spare parts

- Certification: CE,ISO9001

30TPD semi-continuous refining machine. Refining process mainly includes degumming, deacidification, decolorization, deodorization, dewaxing and other sections.Generally, there are three types of refining methods: intermittent refining process,semi-continuous refining process and continuous refining process.Semi-continuous refining process is a kind of mixed process which the interval

1. In batch type vegetable oil refining plant: The acid degumming process generally proceed with alkali deacidification process together. After adding phosphoric acid, stir the oil for about 30 min, and then add alkali liquid to proceed the neutralization reaction.

Edible oil refinery plant manufacturer supplies oil refining machine

- usage: To Extract Oil From Various Oilseeds & Nuts.

- Capacity: 8~10 tons/day

- Voltage: 380V/440V

- Dimension (L*W*H): Depends

- Weight: KG

- Warranty: One year warranty against manufacturing defect.

- Main components: Gearbox

- Oil type: Cooking oil

- Full Warranty Service: Video Technical Support

- After Warranty Service: Spare Parts

- Onsite Warranty Service: Field Maintenance and Repair Service

- Raw material: Sunflower

- Product name: Oil pressing machine

- Function: Edible oil production

- Application: Production of edible oil

- Keyword: Oil expeller

- Used for: Edible oil manufacturing

Edible oil refinery plant manufacturer supplies high quality edible oil refining, dewaxing and factionation machine with factory price and mature oil refining process technology and provide turn-key projects of edible oil refinery plant for you.

Edible oil refining process flow chart introduction

- Usage: Cooking Oil

- Capacity: 1-100TPH

- Voltage: 220V/380V

- Power (W) : 18.5 KW

- Dimension (L*W*H): 2000x1400x1850mm

- Weight: 15TONS

- Certification: ISO CE BV SGS

- mame equipment: fruit crushing machine for cooking

- Raw material: Vegetable seeds

- available markets: Africa, America, Asia

- rsidual: less than 0.6%

- warranty: 1 year

- Function: making cooking oil

- shipping: supplied

- safe: supplied

- advantage: lower costs, energy savings

- technology: the latest

Compared to batch type edible oil refining process, the semi-continuous edible oil refining process has better refining effect, but with high cost. 3. Full-continuous edible oil refining process flow chart. Full-continuous edible oil refining process flow chart is suitable for 30-2000tpd edible oil refinery plant.