Different methods of extraction of essential oil PPT

- Usage: Edible Oil

- Model number: vegetable oil solvent extraction machinery

- Product color: customers' choice

- Voltage: 220/380 Or other

- Residual oil in flour: ≤ 1%

- Capacity: 20-2000TPD

- Steam consumption: ≤ 280 KG/T (0.8 MPa)

- Energy consumption: ≤ 15KWh/T

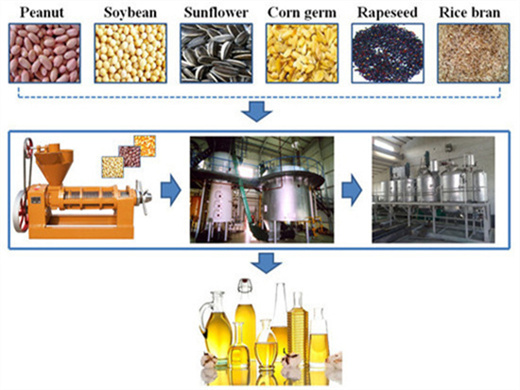

- Raw material: sunflower, peanuts, soybeans, etc.

- Material: Stainless steel and carbon steel

- Price: Negotiation

? In the Solvent-Extraction method of Essential Oils recovery, an extracting unit is loaded with perforated trays of essential oil plant material and repeatedly washed with the solvent. Solvent extraction is used on delicate plants to produce higher amounts of essential oils at a lower cost .

Solvent Extraction. The cotton seed cake solvent extracted or pre-pressed cake or full pressed cake or expanded collets. The pre-pressed cake / expanded collets / fully pressed cake from preparatory section is carried by Redler Conveyor and fed to Extractor Either through rotary valve or Plug O Seal to extractor feed hopper incorporated with high and low level arrangement to ensure proper

Solvent Extraction Edible Oil Processing Wiley Online Library

- usage: To Extract Oil From Various Oilseeds & Nuts.

- Capacity: 500-600 kg/h

- Voltage: 380 V/50 HZ

- Dimension (L x W x H): 2200 x 1400 x 1700mm Weight: 1420kg Main components: Motor, PLC, bearing

- Oil name: manual oil pressing machine

- Keyword: Cooking oil extraction machine

- Diameter (mm): 150

- Raw material: peanut, soybean, sesame, sunflower seeds, camellia seeds, corn germ, etc

- Heater: 4.5 KW

- Application: Oil production line

- Vacuum pump (Kw): 1.5

- Screw speed (r/min): 35

For oleaginous materials with more than 30% oil by weight, such as rapeseed, sunflower, ground nuts, and copra, the material is mechanically and thermally prepared, mechanically deoiled to approximately 20% oil by weight and then sent to the solvent extraction process separation.

Oil Extraction Solvent extraction to release oil from pretreated bran. Desolventization Removing residual solvent from the extracted meal. Refining Degumming, neutralizing, decolorizing, deodorizing, and dewaxing the crude oil for market-ready quality.

Coconut (Copra) Solvent Extraction Plant Oil Expeller and Oil Refinery Machine

- Usage: Cooking Oil

- Capacity: 10T-3000T/D

- Voltage:380V

- Power (W): 18.5 KW

- Dimension (L*W*H): According to your request

- Weight:30tons

- Certification:ISO9001

- Processing:oil refining

- Electricity consumption:28Kwh/T Oil

- Water softening:

- Phosphoric acid:

- Bleaching earth consumption:

- Refining rate:

- Waste Bleaching earth oil content:

- Circulating water Cooling water performance:

- Supplier ITEM: Oil Refining Machine

Solvent extraction by pre-pressing system ; Solvent extraction by full pressing system. The kernels are widely extracted with the help of mechanical expression process using screw presses and also with solvent extraction. The solvent extraction process of coconut will be carried out with the following steps. Method 1: Pre-press with solvent

Therefore, fewer operators are required in an edible oil solvent extraction facility than in an edible oil pressing plant. Lower Energy Consumption: Solvent extraction is a chemical method that does not require hydraulic machinery or an elaborate set-up.

Pragati Agri Products Pvt Ltd Manufacturer of Crude, De ..

- Usage: Cooking Oil

- Capacity: 1-2t/h

- Voltage: 220 V 380 V

- Dimension (length x width x height): 2500x1220x1100 mm

- Weight: 1000kg

- Key Selling Points: Automatic

- Outgoing Inspection Video: Provided

- Main components warranty: 2 years

- Main components: Gear oil

- Maximum oil capacity: depending on model

- Material premium: Cooking fruit

- Function: Cooking oil pressing

- Application range: Cooking fruit

- Feature: high performance efficiency

- Local service location: None

State-of-the-Art Infrastructure: We pride ourselves on our advanced infrastructure, which includes a modern Solvent Extraction Plant and an Edible Oil Refinery Plant. Equipped with cutting-edge technology, these facilities enable us to process large quantities of Rice Bran and produce superior-quality Rice Bran Oil and De-Oiled Rice Bran.

Choosing the Right Solvent: Criteria for Optimal Plant Extracts

- Usage: Edible Oil

- Voltage: 380 V

- Power (W): 5.5 ~ 11 kW

- Dimension (L*W*H): 1700 *1100*1600 mm

- Weight: 1200 kg

- Certification: CE ISO

- Name: cold pressed oil machine for cooking Price

- Advantage: Lower residual oil rates

- Item: Edible oil press

- Delivery time: 20 days

- Product name: Oli Press

- Model: 6YL

- Port: LDngdao/tianjin/ dalian

- Function: Cold/Hot Press

- After-sales service: Service engineers abroad

Selectivity in solvent extraction is important. A good solvent should be able to selectively extract the desired compounds while leaving behind unwanted ones. For example, in the extraction of essential oils from plants, a solvent should be able to dissolve the volatile oil components without extracting excessive amounts of water soluble

- What is solvent extraction?

- Solvent extraction is a continuous process that uses edible grade hexane as a solvent and non-edible grade with a non- flammable solvent. Mecpro has invested for years in research and development for improving the technology used in Solvent Extraction Plants.

- What is the market share of lubricating oil in Bangladesh?

- ant-consumption-rises-prices-stay-high-1859560]Figure 9: Lubricating oil Brand Market Share, Bangladesh 2019 They account for about 50 per cent of the total market share while the remaining half is split up betwe n other brands, according to industry insiders.Mobil leads the charts with 27 per cent market share; it is followed by British Pe

- How many lubricant processing plants are there?

- of 14 New Blending Plants came in operation Lubricant processing plants are installed at different locations of the country producing lubes from USE Way Forward in terms of Regulatory Measures Voice up for regulatory measures on locall

- What lubricants are used in lube manufacturing?

- ment, which, in turn, is a boon for the market. Typical lube manufacturers use crude oil, CBM, tight oil, and other additives to formulate all types of lubricants. Major companies, such as Royal Dutch Shell, Total SA, Chevron, ExxonMobil Corporation, British Petroleum, and Sinopec, hav

- Why is a solvent extraction plant important?

- The design and layout of the solvent extraction plant ensure the easy operation, maintenance, and lubrication of the plant by the operators. It also helps for the smooth running of the plant. Automation in the process ensures consistency in the process and quality of both product and by-product with reduced utility consumption.

- What are the different sections of solvent extraction?

- The solvent extraction is divided into various sections, preparation of raw material, extraction, Desolventization, distillation, absorption, and vent air purification. Each section is having different and advanced technologies from any conventional system prevailing in the global market.