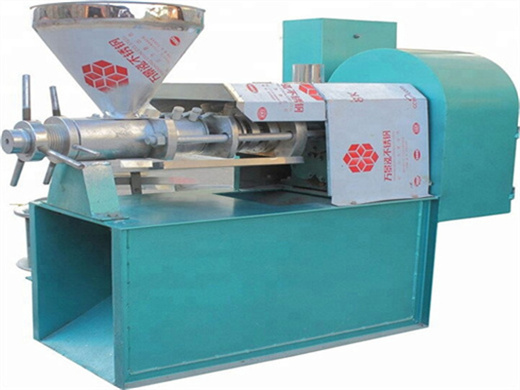

Advanced Castor Oil Extraction & Refining Machine

- Usage: Cooking Oil

- Capacity: 10-20kg/h

- Voltage: 220v

- Dimension (L*W*H): 700X700X900mm

- Weight : 126 KG

- Main components: Engine, Gearbox

- Oil type: Cooking oil

- Control box: Yes

- English manual: Yes

- Filtering system: With single filter

- Delivery time: 7 days

- Feature: Can press kinds of oilseeds

- Name: Oil Pressers

- Raw Material: Oilseeds

- Function: Oilseed Press

- Product Name: Cooking Oil

- Warranty period: 12 months

Step 2: Solvent Extraction for Castor Oil: Castor Oil Cake → Solvent Extraction → Mixed Oil → Settling → Evaporation → Vapor Extraction → Crude Castor Oil; After the harvest of the seeds, they are left to dry. This allows the seed hull to split for the release of the seeds. Castor oil extraction starts with the dehulling of the seeds.

Castor oil merely has less than 0.15% in the international oil seed trade market. For this reason Oil World, a well-known vegetable oil statistics, only note the production, trade and consumption data in the margins. The 1.3 Mt of castor oil seeds produced in total per year corresponds to about 550 kilo tons of oil.

Castor Oil Manufacturing Process Flowchart How to Start a ..

- Usage: Cooking Oil

- Capacity: 1.5-3 tons/24 hours a day

- Voltage: 380 V/50 Hz

- Dimension (L x W x H) : 3840*900*2140 mm

- Weight: 750kg, 750kg

- Color: Stainless steel color, customized

- Capacity: 1.3 ~ 3 tons for 24 hours

- Raw material: Crude oil

- Function: degumming, deacidification, drying and discoloration of crude oil

- Measurement (L*W*H) : 3840*900*2140mm

- Refining tank capacity: 300L/250L

- Suitable oil material: soybean, peanut, sunflower, Cooking, crude flax oil, etc.

- Nature of the company: manufacturer with export rights.

It connects a series of seed processing equipment to continuous oil extraction which can largely saving labor cost in production. The castor oil seeds undergoes many processes to produce castor oil. The following steps: seed cleaning, seed cooking, oil extraction, oil clarification, oil storage and filling.

But have you ever wondered what goes behind making Castor Oil from Castor Seeds? Let’s find out! The Complete Castor Oil Extraction process. Castor oil seed contains about 30%?50% oil (m/m) depending on its variety. Oil can be extracted from castor beans by mechanical pressing, solvent extraction, or a combination of pressing and extraction.

SOLVENTS AND CO-SOLVENTS SELECTION FOR THE EXTRACTION OF ..

- Usage: Cooking Oil

- Voltage: 220V/380V2

- Dimension (L*W*H): 1200*400*900mm3

- Weight: GW 51000kg

- Certification: ISO9001

- Item: Cooking oil press in Ukraine

- Raw material: Vegetable seeds

- Installation: guided by engineers

- Main motor: Y200L-6-18.5KW

- Screw speed: 30-40 r/min

- Vacuum pump: Y100L1-4-2.2KW

There has been a notable demand increase in the manufacturing market globally for castor oil and the products derived from castor oil. Castor oil consists of almost 90% of ricinoleic fatty acid, and it is nearly a pure compound. Castor oil is renewable and naturally occurring. It is known to have

Chemical Properties of the Crude and Refined Castor Oil Property Crude Castor Oil Refined Castor Oil Acid Value [mg NaOH/g of Oil] 1.148 0.869 Saponification Value [mg KOH/g of Oil] 185.83 181.55 Iodine Value [g I2 /100g of Oil] 87.72 84.8 Table 4.

High-Efficiency Castor Oil Extraction Machinery for Optimal ..

- Usage: Edible Oil

- Capacity: 10T-3000T/D

- Voltage: 220V/380V/440V

- Power (W): 10-50kw

- Dimension (L*W*H):1200*400*900mm3

- Weight:According to processing capacity

- Certification :CE ISO BV SGS

- Item: oil cake

- Raw material: peanut/peanut

- Vapor pressure:≥1.2MPa

- Volatile substance in crude oil:≤0.3%

- Steam consumption in refining:≤280kg/ton of oil

- Oil residue in residual clay:&le ;25% residual clay

- Solvent content in crude oil:≤200 ppm

- Oil residue in flour:<1%

- Warranty: 2 years

- Feature:High oil performance efficiency

Castor oil extraction machinery is a special equipment used to extract oil from castor seeds, usually including equipment for multiple links such as pretreatment, pressing, filtering and refining. Castor seeds have a high oil content, but their shells are hard and rich in fiber, so specific mechanical equipment is required to process them.

Castor Oil Extraction, Castor Oil Refining Processes ..

- Usage: Cooking Oil

- Capacity: 100kg-700kg/h

- Voltage: 220V/380V

- Dimension (length x width x height). ): 1500*580*1250mm

- Weight: 150KG

- Main components: motor, pressure vessel, gear, motor, others

- Oil type: cooking oil

- Product name: cooking oil double refining machine

- Keyword: cooking oil double refining machine

- Raw material: cooking soybean

- Power: 2.2-4kw

- Function: all kinds of crude oil

- Capacity: 150kg -1000kg/hour

- Final product:: cooking oil

- Advantage: high oil output rate, low oil loss

- Residual oil: less than 1%

- Service After-sales provided: 1 Year

This section of CastorOil.in provides details and web resources on castor oil extraction. Castor Oil Production. Castor seed is grown commercially on plantations but also harvested from wild plants. The seed must be hulled after harvesting. This can be done laboriously by hand or, more commonly, by machine.