Everything You Need To Know About Cold Pressed Flax Seed Oil

- Usage: Cooking Oil

- Capacity: 20~2000T/D

- Voltage: 380v/50Hz

- Power (W) : up to specification

- Dimension (L*W*H): 1360*950*1170mm

- Weight: up to specification

- Function: oil refining plant

- Capacity model: 10T/H, 30T/H, 45T/H, 60T/H, 80T/H, 100T/H

- Suitable material: soybeans, peanuts and other materials oil derivatives

- Patented product: Yes

- Patent number: ZL2007 20092291.7;

- Fully automatic: Yes

- Technology: Cutting-edge technology in China

- Technology support: lifetime

- Warranty: one year

- After-sales service: offer installation and debugging

While cold pressed flax seed oil doesn’t have exactly the same nutritional benefits as whole flax seeds, it’s still an excellent way to improve your overall well-being. Alongside boosting your Omega-3 levels, you’ll find that adding one or two servings of cold pressed flax seed oil to your daily routine can help fight the following common

Introducing Flax Seed Oil, Cold Pressed, a golden oil extracted from the seeds of the flax plant. It is a rich source of omega-3 and omega-6 fatty acids, which are essential for healthy skin and hair. Flax Seed Oil is known for its ability to deeply nourish and hydrate the skin, leaving it feeling soft, smooth, and plump.

GreenIVe Flax Seed Oil Organically Grown100% Pure Cold ..

- Usage: Cooking Oil

- Capacity: 200TPD cooking oil manufacturing plant

- Voltage: 220V/380V/440 V

- Power (W): depends on capacity

- Dimension (L*W*H): 5432*2636*2345

- Weight: 850 KG

- Certification: ISO9001

- After-sales service provided: Overseas service center available

- Keywords: cooking oil manufacturing plant

- Name: cooking oil manufacturing

- Material: stainless steel

- Request for engineers: 1-2 engineers

- Oil grade: 1st, 2nd, 3rd

- Environmentally friendly: yes

- Business type: manufacturer

- Methods: hot and cold press machine

- rate of oil: 20%-98%

NUTRITIOUS: GreenIVe Flax Seed Oil is loaded with Omegas 3-6-9! 9g Omega-3, 2g Omega-6, 2.5g Omega-9 ; QUALITY: Only the best quality Flax is used when sourcing our Flax Seed Oil. 100% all pure Virgin Cold Pressed Flax Seed Oil. PURITY: GreenIVe products are always Pure and Fresh.

Cal's Flax Oil, Cold-Pressed Flaxseed, High in Omega-3 Fatty Acid, Unrefined Flaxseed Oil, Essential Flaxseed Oil Liquid Supplement for Joint, Skin, and Heart Health Support 16 oz 16 Fl Oz (Pack of 1)

Organic Gold Flax Seed Oil Cold-Pressed, Best Taste

- Usage: Edible Oil

- Capacity: 30T/H

- Voltage: 380v/415v

- Power (W) : As per capacity

- Dimension (L*W*H): According to capacity

- Weight: According to capacity

- Certification: ISO9001, CE, BV

- Project name: 60mt cooking oil mill price

- Phosphoric acid: 2~3kg/T oil

- Residual bleaching earth oil content: <35 %

- Electric consumption: 28kwh/T of oil

- Deodorization loss consumption: ≤0.5%

- Crude oil: Vegetable oil

- Steam consumption: 450kg/T of oil

- Bleaching earth consumption: 5~50Kg/Work

- Cooling water performance by circulating water: 150m3/H

- >cooling water: 13~28℃

Golden flax oil is a rich source of heart-healthy omega-3 fatty acids and nutrient-rich lignans. Providing a fresh and buttery flavored oil, our small batch process starts with sampling golden flax seeds grown in mineral-rich soil from certified organic farmers.

Barlean's Organic Lignan Flaxseed Oil Liquid Supplement from Cold Pressed Flax Seeds, 7,230 mg ALA Omega-3 Fatty Acids, Cold Press Flax Seeds for Joint & Heart Health, 32 oz Oil 32 Fl Oz (Pack of 1)

Flax Seed Oil Caps Biotics Research

- Usage: Edible Oil

- Capacity: 30 tons to 1000 tons per day

- Voltage: 380V

- Dimension (L*W*H): According to production capacity

- Weight: 10000 KG

- Main components: motor, pressure vessel, pump, bearing, motor

- Oil type: cooking oil

- Raw material: carbon steel, stainless steel

- Product name: Oil press machine

- Range of application: cooking oil production

- Advantage: High oil yield

- Residual oil rate in the cake: 1%

- Certificate: CE, ISO, BV...

- Post-warranty service: video technical support, online support, spare parts, Fie

Flax Seed Oil Caps supplies pure, cold pressed flax seed oil, from certified organically grown flax seeds. Flax seed oil is a natural source of essential fatty acids, especially omega-3 fatty acids (ALA).

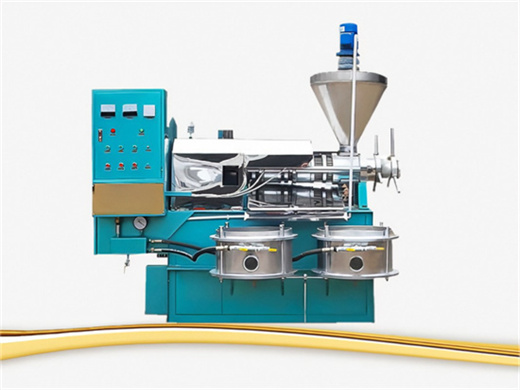

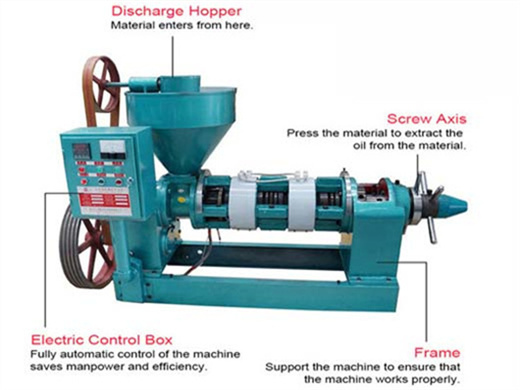

VEVOR Oil Press Machine 750W Cold / Hot Press Automatic Oil Processing Machine

- Usage: Cooking Oil

- Capacity: 5TPD

- Voltage: 220V/380V

- Dimension (length x width x height): 800*650*1100mm

- Weight: 530 kg

- Main components: PLC

- Oil name: Hot oil presser for Neem oil making

- Application: Line of oil production

- Advantage: Energy-saving hydraulic oil pressing machine for cooking oil extraction

- Material: 304 stainless steel

- Color: Vegetable Silver Seed Oil Extraction Machine

- Capacity: Small Home Cooking Oil Making Philippine Virgin Oil Extraction

- Local Service Location: Vietnam, Nigeria

VEVOR Oil Press Machine 750W offers 95% oil yield with hot, cold, and frying press options, featuring durable stainless steel and 24-hour continuous operation.

- How is flaxseed oil processed?

- The Best Flaxseed Oil Processing Method Flaxseed oil contains an adequate amount of linolenic acid and the oil is usually extracted by low-temperature physical squeezing in the flaxseed oil production line.

- Why is flaxseed oil pressed?

- The pressing production process keeps the most effective ingredients in flaxseed, such as polyunsaturated fatty acids, protein, dietary fiber, vitamins, trace elements and so on. The pressed oil is more suitable for a special supplement for human health.

- Why is pressed flaxseed oil better than pressed wax?

- Second, the physical pressing temperature is lower than the melting point temperature of the wax, so that the pressed flaxseed oil is free from the “dewaxing” procedure and avoids the damage caused by the dewaxing process.

- How to make flax seed oil?

- Therefore, when making flax seed oil, it is necessary to choose the physical pressing method at low temperature without any heating treatment. Low-temperature physical squeezing retains the activity of linolenic acid, and no additives in the whole process to maintain the natural quality of raw materials.