Processing canola seed into oil and meal in Canada

- Usage: Cooking Oil

- Capacity: 98%

- Voltage: 220V/380V/440V

- Power (W): 11KW

- Dimension (L*W*H): 1.5*2.6*3.6M

- Weight: 0.5-10T

- Certification: ISO9001,CE, BV

- Product name: cooking oil production mill

- Raw material: Vegetable seed

- Application: all kinds of oil seeds

- Function: get grade 1 cooking oil

- Warranty: 365 days

- Feature: High efficiency multifunction

- Model: LD88

- Quality: 15 years of service

- Advantage: 35 years of experience

- Color: Nippon

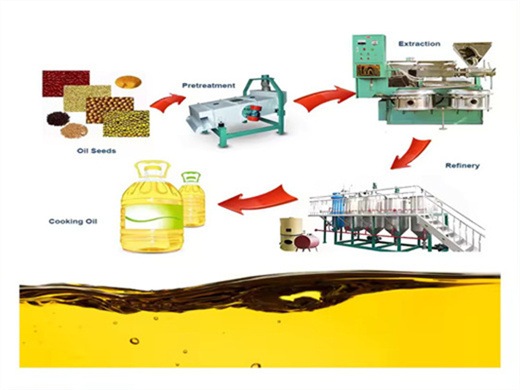

How canola seed becomes oil and meal products. The process for turning canola seed into oil and meal is similar to how other oilseeds are processed. Seed is preconditioned and pressed to separate the oil from the solids. Further refining and processing create finished canola products, ready for the market or further processing. Learn more about:

canola oil refining making machine manufacturer in qatar. Machine Type: canola oil refining machine; Production Capacity: 4.5 TPD; Dimension(L*W*H): 700*550*800mm; Power: 141kw; Plant Phosphoric acid:0.1-1 kg/T oil

Commercial Processing of Canola and Rapeseed: Crushing

- Usage: Cooking Oil

- Capacity: 5TPD

- Voltage: 220V/380V

- Dimension (L*W*H): 900*750*1400mm

- Weight: 880kg

- Name: Cooking Oil Extraction Cooking Pressing Cocoa Butter Pressing Machine

- Nominal pressure: 2200KN

- Working pressure: 55Mpa

- Power of electric heating coil: 1KW

- Control temperature of heating coil: 70-100℃

- Each feeding time: 2-7kg/ 8min

- Function: cocoa butter pressing machine

- Certification: CE

The canola seed is obtained from Brassica campestris and Brassica napus species. Seed should be well matured and contain less than 3.0% damaged seeds including not more than 2.0% distinctly green seeds and not more than 0.1 % heated seeds. In order to qualify as canola, the oil from the seed must contain less than 2.0%

qatar; saudi Arabia ; somalia; rwanda; sudan one grade oil level canola oil processing machine in saudi Arabia vegetable seed oil press machine vegetable seed

canola oil processing machine

- Usage: Cooking Oil

- Voltage: standard

- Power (W): standard

- Dimension (L*W*H): standard

- Weight: standard

- Certification: ISO and CE

- FOB Price:

- Shipping:

- Minimum order quantity: 1 set/sets Minimum order quantity 1 set

- Payment terms:

- rotation speed: 36 r/min

- diameter of juicer chest: 132 mm

- Materials:

- Oil quality:

- cooking oil machinery:

one grade oil level canola oil processing machine in saudi Arabia. Machine Type: canola oil processing machine; Production Capacity: 100~150TPD(24hrs)

Niger Seed Oil Processing. The most convenient and economical way to extract oil from niger seed is using a niger seed oil extraction mill. The oil extraction mill produced by us is easy to operate and repair. It can not only process niger seeds, but also many other

Improving Oil Extraction from Canola Seeds by Conventional ..

- Usage: Cooking Oil

- Capacity: 1-100T/D

- Voltage: 380V/440v

- Power (W) : 20-50KW

- Dimension (L*W*H): 2050*1350*2000mm

- Weight: 800kg

- Main exporting countries: Asia, Africa, Latin America, Malaysia...

- Packaging: Glass container, Plastic container

- Grade: first grade

- refined oil: 1st grade

- oil content: 35%-48%

- fat: 40~60.7

- protein: 20~37.2

- phospholipid: 1 .25~1.75

- saccharides: 5~15

- Refiney type: cooking oil equipment

PDF On Nov 23, 2018, Mohamed Ahmed Fouad Mohamed Mohamed Gaber published Improving Oil Extraction from Canola Seeds by Conventional and Advanced Methods Find, read and cite all the research

Exploring More Efficient Canola Processing Machine

- Usage: Cooking Oil

- Capacity: 100 tons/day

- Voltage: 0

- Dimension (length x width x height): 36*15.5*31 cm

- Weight: 8 kg, 800 kg

- Main components: others

- Oil Raw material: Cooking/coconut/peanut/linseed/soybean

- Material: stainless steel

- Capacity: 3~600 kg/hour

- Function: Making edible oil

- Advantage: Energy saving

- Automatic: Manual

Although canola oil is a common ingredient today in grocery stores, restaurants, and home kitchens, the popular commodity has a relatively short history compared to other oilseeds. Since canola oil first hit the market in the 1970s, canola processing has quickly advanced as crop varieties and pressing methods have evolved.

- What is a Canola Oil Processing Plant?

- A Canola Oil Processing Plant is a small scale facility for extracting canola oil using a pressing method. The rapeseeds are cleaned, roasted, screw pressed, and refined using the canola oil processing equipment. The rapeseed oil press machine used in this process has the functions of automatic barrel heating, pressing, and oil filtering.

- What is a canola oil press machine?

- The rapeseed oil press machine is a piece of equipment used in the canola oil processing plant. It performs the functions of automatic barrel heating, pressing, and oil filtering. The feeder equipped helps increase production efficiency and save labor.

- What is the process for canola seed processing?

- To process canola seeds, we need basic equipment including a Seed Cleaner, Seed Cooker/Kettle, Oil Press, Filter Press, Steam Boiler, Screw Conveyors, and Bucket Elevators. The process begins with seed cleaning, where canola seeds are separated and cleaned to remove impurities such as dust, metal, and plant stalks.

- How is canola oil extracted?

- Canola oil is extracted using two main methods: Mechanical Press and Solvent Extraction. In the Mechanical Press method, Canola oilseeds are pressed in a series of Screw Presses / Expellers. This process does not use chemicals and leaves approximately 5-7% oil in the residual Cake/Meal.

- Which countries produce canola oil seeds?

- The major producers of canola oil seeds are the European Union, Canada, China, and India. The European Union and Canada are among the leading producers, and the Canola (and Rapeseed) oil is the 3rd leading source of vegetable oil, after soybean and palm oil.

- How is canola oil filtered?

- Canola oil is filtered through a two-step process. First, the extracted oil is transferred to a Vibro Separator or Screening Tank for preliminary separation of suspended solids, known as 'foots'. Then, the pre-cleaned oil undergoes final filtration in a filter press or vertical pressure leaf filter to obtain filtered canola oil.