Enhanced castor seed oil extraction assisted by the ..

- usage: To Extract Oil From Various Oilseeds & Nuts.

- Voltage: 220V/380V or local voltage

- Power (W): According to capacity

- Dimension (L*W*H): 1610x615x1260mm

- Weight: 1050 KG

- Certification: BV/CE/ISO

- Name: cooking oil press equipment

- Model: QI E

- Certifications: BV/CE/ISO

- Turnkey project: YES

- Overseas engineering service: YES

- Guide installation service: YES

- Warranty: 5 years

- Port: Qingdao or the nearest port

Recently, Naveenkumar & Baskar [41] reported optimum conditions of 16:1 solvent (isopropanol + methanol)-to-seed ratio, 9 min extraction time, 50 °C temperature for castor oil extraction under the influence of ultrasounds to obtain maximum extraction yield of 70.08%. Castor oil extraction yield of up to 35% was reported by Mosquera-Artamonov

But have you ever wondered what goes behind making Castor Oil from Castor Seeds? Let’s find out! The Complete Castor Oil Extraction process. Castor oil seed contains about 30%?50% oil (m/m) depending on its variety. Oil can be extracted from castor beans by mechanical pressing, solvent extraction, or a combination of pressing and extraction.

Castor Oil Manufacturing Process Flowchart How to Start a ..

- Usage: Edible Oil

- Voltage: 380V

- Power (W): according to capacity

- Dimension (L*W*H): according to capacity

- Weight: various

- Certification: CE and ISO

- After-sale service provided: Overseas service center available

- Raw material: Vegetable seeds

- Capacity : 5-600T

- Function: crude cooking oil biodiesel

- Manufacturing experience: 20 years experience

- Equipment material: stainless steel and carbon steel

- Oil yield rate: 85%

- Market: more and more countries are asking for biodiesel

Here are the basic steps to extract the castor oil. Step 1: Castor Seed Dehulling. Step 2: Castor Seed Cleaning. Step 3: Castor Seed Cooking. Step 4: Castor Seed Pressing. Step 5: Castor Oil Clarification. Step 1: Castor Seed Dehulling. Castor seed contains about 30%?35% oil. The extraction process begins with the removal of the hull from the

We are a Family Owned Company and Pioneer in Planning, Engineering, Manufacturing and Installation & Commissioning for Automatic Oil Mill Plant, Palm Kernel Oil Extraction Plant, Solvent Extraction Plant, Edible Oil Refinery Plant, Fish, Poultry & Animal Feed Plant, Oleochemical Plant Flour Mill Plant, Rice Mill Machinery, EFB, MSW, Plastic

Oil Extraction Machines Complete Guide

- Usage: Cooking Oil

- Capacity: 1-100T/DAY

- Voltage: 220V/380V

- Dimension (L*W*H): 1500*1200* 1700 mm

- Weight: 780 KG

- Main components: Motor

- Oil type: Cooking oil

- Product name: Expelle screw press of oil

- Raw material: Stainless steel

- Function: Edible oil manufacturing

- Application: Edible oil processing plant

- Advantage : High efficiency

- Feature: High oil pressing rate

- Capacity: 80-1800 kg/h

- Quality: Excellent

- Package: Standard wooden box

- After-sales service provided: Online support

The cold press oil machine is an oil extraction machine with a mechanical working principle, which ensures the extraction of oil by putting the seeds under high pressure. Cold press oil machines extract oil at a much lower temperature than hot press oil machines. The oil pressing process at low temperatures ensures that the oil is produced of

This paper carried out experimental study, through extraction and characterization of both crude and refined castor oil. Normal hexane was used as solvent for the extraction process. The oil produced was refined through degumming, neutralization and

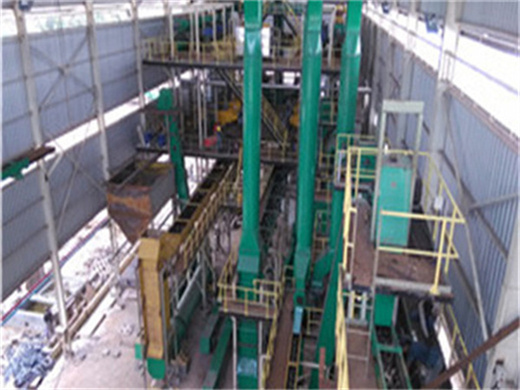

Complete Castor Seed Oil Extraction Plant, Oil Mill Machinery ..

- Usage: Cooking Oil

- Voltage: 380v

- Main components: motor, gear, bearing

- Oil type: cooking oil

- Function: make edible oil

- Advantage: High oil yield

- Character: 100% physical press

- After-sales service provided: video technical support, online support

In Reaction Vessel, the castor oil is heated by steam heating coils up to 60 70oC followed by open steam injection to increase moisture content with continuous Agitation allowing the temperature to reach 100 110 oC.

Commercial Expeller Castor Seed Oil Press Machine

- Usage: Cooking Oil

- Capacity: 30 kg/h

- Voltage: 220 V, 380 V

- Dimension (L*W*H): 850*750*1450 mm

- Weight: 580 KG

- Main components: Motor

- Raw material: Cooking

- Function: Oil pressing

- Working pressure: 60MPa

- Piston stroke: 300

- Pressing time: 7-8min/times

- Heating temperature: 0-150 ℃

- Application: Oil production line

- Oilseed extraction: 98% oil yield

- Quality: Top level

Goyum Screw Press Offering Commercial Expeller Castor Seed Oil Press Machine at 10375000 in Ludhiana, Punjab. Also find Oil Expellers price list ID: 24324289488

- How does a castor seed extraction machine work?

- Due to cooking, the oil droplets in the seeds come together and also the cell wall is broken, this results in improved oil yield and low power consumption. A continuous screw press is used to extract the oil. The castor seed passes through the machine where the screw shaft is rotated in the parallel direction and crushing the seeds.

- Where is castor seed oil extracted?

- We are experienced in turnkey Castor Seed Oil Extraction Plants. Our machines are working successfully in over 55 countries. Major Castor Seed producing countries are Brazil, India and Argentina. Other countries growing Castor include Indonesia, Indo-China, Madagascar, Angola and Mozambique.

- What is castor oil extraction machine?

- To extract the oil they must be crushed and pressed with screw pressing at high or low temperature. The castor oil extraction machine is an advanced vegetable oil press machine, characterized by its simple design, easy operation, wide suitability and continuous operation, high productivity and high oil output rate.

- How is castor oil extracted?

- The initial phase of oil extraction is done through pre-pressure. It is usually done using a high pressure, which uses continuous screw press with the help of a seed oil press machine. The extracted castor oil is sprinkled. The material that is extracted from the press is called castor cake.

- Who is the best seed cleaner manufacturer in India?

- We are well reckoned as the most preeminent seed cleaner manufacturer and one of the supreme seed cleaning machine suppliers from India. Castor Seeds obtained after the Cleaning process can be used as a raw material for Castor Oil Press. Castor seeds contain 45 – 50 % oil content.

- How Castor seed oil mill works?

- In the castor seed oil mill, the seed undergoes the following steps: seed cleaning, seed cooking, oil extraction, oil clarification, oil storage and filling. After the hull is removed from the seed. The castor seeds had some foreign materials and dirt which was separated by Seed Cleaner.