Dry mortar manufacturing and wall putty production line ..

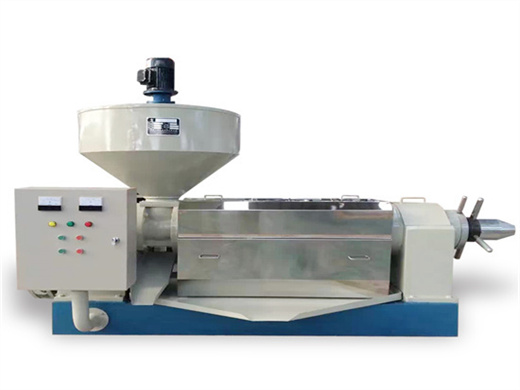

- Usage: Edible Oil

- Capacity: 200-300 Kg/h

- Voltage: 380V/50HZ/Three-phase

- Dimension (L*W*H): 2150*770* 1800mm

- Weight: 900KG

- Raw material: Seeds

- Function: Making edible oil

- Advantage: Energy saving, simple operation

- Price: Factory Price

- Material: Stainless Steel

- Application: Edible Oil Production

- Color: Customer Made

Home; About; Dry Mortar Production Line. Dry Mortar Mixing Plant(stepped Type + Sand Dryer + Loading Spouts + Bagging 80T/H) Dry Mortar Plant (Tower energy-saving + + Loading Spouts + Bagging 80-120T/H)

Asphalt Mixing Plants (Batch/Drum Type) The asphalt mixing plant has a capacity of 20-400 t/h .We mainly provide different types of asphalt mixing plants: ALQ Stationary Asphalt Batch Mix Plant, ALT Asphalt Drum Mix Plant, ALYT Mobile Asphalt Drum Mix Plant for various asphalt hot mixing situations.

Dry Mortar Production Line Dry mortar production line|Wall ..

- Usage: Cooking Oil

- Capacity: 5TPD-100TPD

- Voltage: 220V/380V

- Power (W): 3kw

- Dimension (L*W*H): 1260*1300* 850 mm

- Weight: 28800 kg

- capacity: 40-60 kg/hour

- Heating power: 1.5 kw

- Rotation speed: 63r/min

- Raw material: Oilseeds

- >Application: Line of oil production

- Material: Stainless steel

- Function: Oil press + Drum filter

- Advantage: Energy saving

80T/H dry mortar mixing plant and dry mortar production line stepped layout unit: river sand dryer, pulse dust collector, bucket conveyor, cement silo, probability vibrating screen, automatic batching system, auxiliary raw material weighing and batching system, mixing center (Dual Axis Gravity Free Mixer or Plough Shear Mixer ), finished dry

These dry mortar plants can add configurate with a crushing machine, screen machine, and drying machine, in the area of lack of dried sand. Components of a Dry Powder Mortar Mixing Plant: Storage Silos: The plant typically includes storage silos or bins where different dry powder materials, such as cement, sand, additives, and fillers, are stored.

Basic components of a commercial dry mortar mixing plant

- usage: To Extract Oil From Various Oilseeds & Nuts.

- Voltage: 220V, 380V

- Power (W): according to your capacity

- Dimension (L*W*H): Our engineer will design it according to your capacity

- Weight: According to processing capacity

- Certification: CE,BV,ISO9001

- Supplier type: cooking ejectors

- Features: baking machine high quality cooking oil extraction

- Main fatty acid: in cooking oil

- Free fatty acid: 20%

- Caproic acid: 2%

- Sunflower acid: 9%

- Caprylic acid: 9%

- Oleic acid: 2%

- Capric acid: 2%

- Processing capacity: 5-1000TPD

Home; About; Dry Mortar Production Line. Dry Mortar Mixing Plant(stepped Type + Sand Dryer + Loading Spouts + Bagging 80T/H) Dry Mortar Plant (Tower energy-saving + + Loading Spouts + Bagging 80-120T/H)

As a critical component in dry mortar production, pre-mix hoppers play an essential role in ensuring the efficiency and consistency of the manufacturing process. This article provides a detailed overview of what pre-mix hoppers are, their functions, and how they contribute to the overall effectiveness of dry mortar plants.

Dry Mix Plant / Wall Putty Making Machine Dry mortar ..

- Usage: Cooking Oil

- Dimension (L*W*H): 1750*1150*1720mm

- Weight: 600 KG

- Warranty: 3 years

- Components main: motor, pressure vessel

- Oil type: cooking oil

- Product name: cooking oil making machine

- oil type: oil kitchen, sunflower

- item: cooking oil press machine

- function: Oil pressing

- oil cake: the oil left in the cake is less than 6%

- Raw material: vegetable seeds, cooking,

- Key word: save labor and save cost

- Used for: Commercial oil expeller

- Application range: cooking, etc.

- Pressing method: Screw squeezed press.

Dry Mix Plant / Wall Putty Making Machine (Mini Simple Unit) Wall putty production line,Wall Putty Manufacturing Plant, wall putty powder mixer, dry mortar production line, tile adhesive production line,Tile Adhesive Manufacturing Plant:The unit adopts ladder type layout, the unit includes: bucket elevator,Dual Axis Gravity Free Mixer, pulse jet bag house, valve bag powder packaging […]

Asphalt Mixing Plant in the Philippines Have Branch in Manila!

- Usage: Cooking Oil

- Capacity: 1TPD-1000TPD

- Voltage: 220V/380V440V

- Power (W): 10 -50kw

- Dimension (L*W*H): 1610x615x1260mm

- Weight: 1050 KG

- Certification: ISO9001/CE/BV

- Item: Selected materials Cooking oil pretreatment equipment

- Volatile substance in crude oil: &le ;0.3%

- Main process: measuring, cleaning, crushing, softening, flake

- Solvent content in crude oil: ≤200 ppm

- Control system: electric interlock control system

- Material: stainless steel

- Capacity: 60-200T/D

- Consumption: Low consumption

- , long-term technical support

- Structure: Tower structure

ALT Asphalt Drum Mix Plant. Hot Model 40t/h, 80t/h, 120t/h, etc. Production Capacity: 40-120 t/h; Finished Asphalt Storage Bin: 3-9 tons;