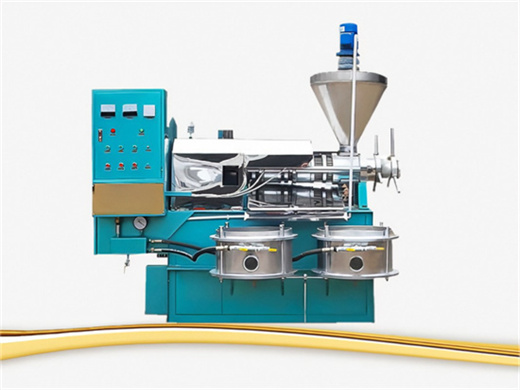

Small Edible Oil Solvent Extraction Plant. Affordable Tank ..

- usage: To Extract Oil From Various Oilseeds & Nuts.

- Board model number: JC-7B

- Color and page: Multicolor

- Voltage: 220/110 V

- Dimensions (length *width*height): 1000 mm x 810 mm x 1320 mm

- Weight: 140 KG

- Main components: Motor-driven

- Product name: Machine hot pressing for t-shirts

- Function: Multi-surface sublimation

- Color: Blue

- Use on: T-shirt.fabric. Fabric

- MOQ: 1 set

- Features: Customized

- Temperature range: 0-399 degrees

- Time range: 0- 999s

The tank extractor is a small-scale batch-type edible oil solvent extraction equipment. It has both the function of extraction and meal desolventizing. It is ideal equipment for a small-scale edible oil mill plant. The capacity is 3 TPD, 5 TPD, and 10 TPD.

Edible oil extractor is the main equipment in the solvent extraction process. The pretreated oilseeds or pre-pressed oil cake are sent to the edible oil extractor by the conveyor, after solvent extraction, miscella and the wet meal are obtained.

Small Edible Oil Extraction Machine

- Usage: Edible Oil

- Capacity: 10tpd-100%

- Voltage: 220V/380V

- Weight: 80 KG

- Main components: PLC

- Oil type: Plant Cooking oil

- Raw material: flowers, herbs, etc.

- Function: Cooking oil distiller

- Application: flowers, herbs, etc.

- Material: 304 Stainless Steel

- Advantage: Energy Saving

- Item: Cooking Oil Extractor

- Name: Stainless Steel Cooking Oil Distiller

- Color: Sliver

The cake feeding, meal discharging, fresh solvent feeding and thick miscella discharging are all completed in batch.Usually, a battery of two or more extraction tanks is used to form a concentration gradient. The small oil extractor is an ideal edible oil extraction equipment for small-scale oil factory. The capacity of mini solvent extraction

Edible Oil Extraction Equipment. Overview. Edible oil extraction equipment or tank extractor is a small-scale batch-type edible oil solvent extraction equipment. Tank extractor has both the function of extraction and meal desolventizing.It extracts oil by immersing the pre-pressed cake in solvent or miscella of various concentrations. Features

Edible cooking oil making machine manufacturer customize ..

- Usage: Edible Oil

- Weight (KG): 500

- Main components: motor, pressure vessel, pump

- Product name: used oil purification plant made in China, used oil refining machine

- Application: used diesel oil filtering

- br>Material:Q235

- Filter media: silica gel or mineral sand

- Size: 0.8 mm

- Length: 1300 mm

- color: blue / gray /white

- power: 7.5 kw or 11 kw

Type 1: Batch Type Cooking Oil Refining Machine 30-2000tpd cooking oil solvent extraction plant; 1-1000tpd crude edible oil refinery plant;

Batch-type edible oil refining equipment offers a practical solution for small-scale edible oil production, combining flexibility, efficiency, and high-quality output. Its modular design, ease of operation, and cost-effectiveness make it an excellent choice for the small-scale oil mill plant, ideal for producing high-quality refined edible oil

kg per day solvent oil extraction plant in lesotho

- Usage: Cooking Oil

- Capacity: according to capacity

- Voltage:380V or 440V

- Power (W): according to capacity

- Dimension (L*W* H): according to capacity

- Weight: according to capacity

- Certification: BV and CE

- solvent:

- residual oil in cake:1%

- extraction capacity: new style Sale of machinery for oil refining

- Material equipment:Stainless steel or carbon steel

- Raw material: corn oil, oil cake, sunflower seed, etc.

- Extractor system:Roasting system

- Use:

- Solvent:

kg per day solvent oil extraction plant in lesotho . Use: cooking oil; Product Name: cooking oil extraction plant; Machine Type: oil extraction plant; Oilseeds: cooking; Production Capacity: 50T~150T/D(Capacity can customized) Voltage:220V, 380V, or other; Dimension(L*W*H):1400*600*600mm

Edible Oil Solvent Extraction Plant Oil Refinery Plant ..

- Usage: Cooking Oil

- Capacity: high

- Voltage: 220V/380V

- Dimension (L*W*H): customization

- Weight: 1100 KG

- Main components: motor, pressure vessel, PLC, gear, bearing, motor, gearbox

- Oil type: cooking oil

- Material premium: sunflower

- Function: oil pressing

- Application: Edible oil press

- Name: Automatic edible oil machine

- Capacity: Large

- Feature: High oil yield efficiency

- Keyword: Seed Oil Press Machine

- Certification: ISO Package

- : Wooden box

- Keyword 2: Cold press oil extractor machine

The solvent extraction plant is part of vegetable oil processing plant which is designed to extract oil directly from oil seed containing less than 20% oil like soyabean fter flaking or it extracts oils from prepressed or fully pressed cake of seeds containing more than 20% oil like sunflower, peanuts, cotton seed, palm kernel, canola, copra

- What is solvent extraction?

- Solvent extraction is a chemical oil extraction method to process oil out from vegetables, oilseeds and nuts by solvent, and Hexane is the preferred choice. Industrial oil processing for the edible oil generally involves the solvent extraction step which may or may not be preceded by pressing.

- What is a batch type solvent extraction plant?

- In batch type solvent extraction plants, a diffusion process takes place. Due to their high steam and labor requirements, such plants are being steadily replaced with continuous solvent extraction plants, whose main component is the extractor which can be either of the immersion or percolation type.

- How much oil can be extracted using solvent extraction method?

- For such processes, it is possible to achieve oil yields in excess of 95% with a solvent recovery of over 95% which in compare to 60 to 70% oil yield by mechanical expeller pressing method. The solvent extraction method will remove all but about ½% of residual oil, uses less hp, and requires less maintenance.

- Which oil extraction process is best?

- This combination combines the best of each system: the pressing operation removes the higher percentages of oil which are by far the easiest to squeeze out of the solids, and the solvent extraction process is best at removing oil from about 20% down to near 0.5%.

- How do you extract solvent from a cake?

- Solvent extraction is achieved through the grinding of seed. The ground seed or cake is then purged or washed with a petroleum distillate (the most common chemical used is hexane) which releases the oil in the seed. The solvent is then “flashed off” by heating the oil in a sealed chamber.

- Does solvent extraction remove oil from protein meal?

- The solvent extraction method will remove all but about ½% of residual oil, uses less hp, and requires less maintenance. It is relatively efficient and reliable, and this is one reason why solvent extraction is the primary means of separating large tonnages of oil from protein meal.