Solvent Extraction Method for Edible Oil Processing

- Usage: Cooking Oil

- Capacity: 1-100T/D

- Voltage: 380V/440v

- Power (W) : 20-50KW

- Dimension(L*W*H): depends on capacity

- Weight: depends on capacity

- Certification: ISO9001/BV/ CE

- Main exporting countries: Asia, Africa, Latin America, Malaysia. ..

- Packaging: Glass container, Plastic container

- Grade: first grade

- refined oil: 1st grade

- content of oil: 35%-48%

- fat: 40~ 60.7

- protein: 20~37.2

- phospholipid: 1.25~1, 75

- saccharides: 5~15

- Refinery type: cooking oil filtering machinery

It is worth noting that a plant to process rapeseed with prepressing followed by extraction will often reduce the oil content from about 40% to 20% in the presses and from 20% to 0.8% in extraction, and that (after adjustments for moisture changes during the process) the press oil produced may be roughly 25.8% of the raw seed, while the

Hot solvent, sprayed on top, percolates through the material, extracting the oil. The solvent is then removed from the oil and the solid residue. Solvent extraction can reduce oil levels below 1%. Oil volume above 300, 000 kg/day are solvent extracted. 23/2/2020 Dr. Mohammed Danish 4

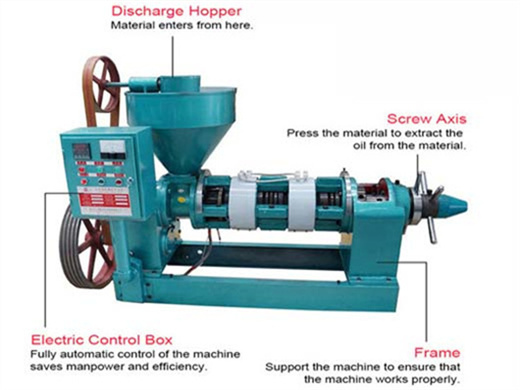

Solvent Oil Extraction Plant for Edible Oil

- Usage: Cooking Oil

- Capacity: up to 4500 kg/h

- Voltage: 220 V

- Dimensions (L*W*H): 84X24X54

- Weight: 67 KG

- Main components: motor, pressure vessel, PLC, bearing, motor, gearbox

- Oil type: cooking oil, black cumin oil, oil from argan, hemp oil

- Advantage: easy to use and easy to use. clean

- Used for: More than 100 seeds and nuts

- Material: Stainless steel and hardened steel, chrome plated

- Features: Speed adjustment

- li>Oilseed extraction: Yes

- Processing types: Screw pressing

- Post-warranty service: Spare parts

- Certification: CE

The basic process is to immerse oil flakes (or pre-pressed cakes) in selected solvents, dissolve oil in solvents (composing mixed oil), then separate the mixed oil from solid residues (meal), evaporate and strip the mixed oil according to different boiling points, so that the solvent vaporizes into vapor and oil separates, thus obtaining oil (extracted crude oil).

The oil milling process involves a variety of steps that take place within an oil processing plant which eventually produce edible or crude oil. One of the most important steps in the processing of oil is the solvent extraction stage which involves the removal of majority of the oil within the seed.

Oilseeds crushing Vegetable oil extraction De Smet ..

- Usage: Cooking Oil

- Capacity: 55 l/hour

- Voltage: x

- Dimension (length x width x height): 37.5 x 37.5 x 65. 8 cm

- Weight: 11 kg

- Main components: volume

- Oil capacity: 55L

- Material: 304 stainless steel

- Net weight: 9.5 kg

- Packaging weight: 11 kg

- Advantage: Energy saving

- Feature: Eco- Friendly

- Function: drawing machine

- Quality: Excellent

- Operation: Easy

- MOQ: 1 Set

Oilseeds crushing and Vegetable oil extraction are pillars of DSEC’s expertise in the construction of Vegetables Oils and Fats Production factories; this guarantees the process and performances to optimize your production.

oil refining plant manufacturing machines in kabwe. Type:Oil Extraction Machine; Production Capacity:1-5T/DAY; Model Number:Edible oil refinery; Voltage:220V; Power:35200; Dimension(L*W*H):15*6*6M; Weight:4000KG; Certification:ISO; Waste bleaching earth oil content: 35%Edible oil refinery:for coooking oil; Bleaching earth consumption:3~5Kg/T oil

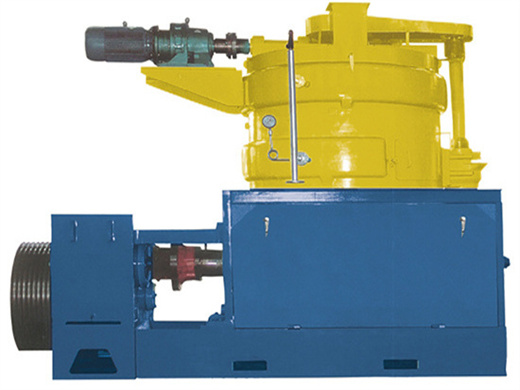

Solvent Extraction Process edible edible oil extraction

- Usage: Cooking Oil

- Capacity: 80-800kg/h-99%

- Voltage: 1.1kw

- Dimension (L*W) *H): 710*950* 1560mm

- Weight: 950kg

- Name: Hydraulic Biodiesel Black Oil Pressing Machine Price

- Model: 6YY-250

- Material Premium: Cooking, camellia, Cooking, avocado

- Function: Oil press

- Power (W): 1.1KW

- Advantage: Simple operation

- Range of application: Oil expeller machine

- Price: Factory price

- Quality: CE ISO Certification

- HS code: 8479200000

- Post-warranty service: video technical support, online support, spare parts, field repair and maintenance service

This process involves extraction of oil from materials that produce oil using a solvent. The most commonly used solvent is hexane, a petroleum byproduct. This process is made possible with the help of solvent extraction plants. The particular oil in question is extracted using chemicals through a series of processes.

Buy and Sell Used Edible Oil Plants Perry Process

- Usage: Edible Oil

- Capacity: 100%, 5T-200T per hour

- Voltage: 380V/50HZ, 380V /440V or local voltage

- Power (W): 15KW, According to capacity

- Dimension (L*W*H): 1700 *1100*1600mm, According to capacity

- Weight: 1200kg, According to capacity

- Certification: ISO

- Keyword: cooking oil processing machine

- Supplier Type: Factory (more than 35 years of experience)

- Capacity: 5T-200T per hour

Oil Extraction Plant, 400 Tons/Day. Stock #RG9680. Used oil extraction plant previously used to produce edible pomace oil, lampante oil and dry biomass from olive and seed pomace (waste from first oil extraction). Plant was built in 1990 and shut down in 2017, with capacity reported to Location: Europe. View Details

- What is edible oil manufacturing plant project report 2025?

- IMARC Group’s report, titled “Edible Oil Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue” provides a complete roadmap for setting up an edible oil manufacturing plant.

- What is edible oil processing?

- The edible oil processing industry revolves around the production, processing and packaging of oils derived from vegetable sources, specifically seeds or nuts. These companies operate at various stages of the oil cycle, including cultivation, extraction, refining and distribution.

- What has been covered in the edible oil manufacturing plant report?

- The following aspects have been covered in the edible oil manufacturing plant report: The report provides insights into the landscape of the edible oil industry at the global level. The report also provides a segment-wise and region-wise breakup of the global edible oil industry.

- How does edible oil refinery work?

- The edible oil refinery plant receives crude oil after it has been obtained. This stage is critical for refining the oil to meet food-grade standards. Equipment for refining includes deacidifies, deodorizers, and bleaching machines. These remove impurities, free fatty acids, and undesirable flavors from the oil, ensuring it is safe for consumption.

- How is the edible oil market shaped?

- The edible oil market is shaped by a combination of market drivers and evolving trends that reflect changing consumer preferences, health consciousness, and global economic dynamics. The ever-increasing global population drives consistent demand for edible oils as they are a dietary staple in most cuisines.

- What is an Oil Expeller Plant?

- An oil expeller plant specifically presses or expels the oil from seeds, delivering an unrefined product ready for purification. The edible oil refinery plant receives crude oil after it has been obtained. This stage is critical for refining the oil to meet food-grade standards.