Used lubricating oil recovery process and treatment ..

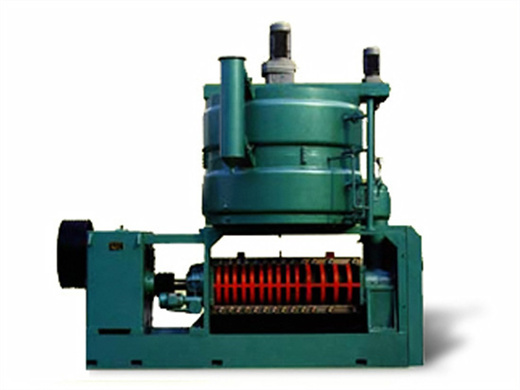

- Usage: Cooking Oil

- Capacity: 80-600 KG/H

- Voltage: 110V, 280V, 380V, 440V

- Power (W): according to capacity

- Dimension (L*W*H): 1610x615x1260mm

- Weight: 1050 KG

- Certification: CE,BV,ISO

- name: edible Cooking oil press

- texture: carbon steel and stainless steel

- workmanship: 1 person per shift

- motors: special for Cooking oil expeller plant

- package: wood special cases for Cooking oil expeller plant

- land area: according to capacity

- color: according to client

- materials: Cooking, all edible materials

- final products: edible oil, oil cake for animal feed

- filter: with vacuum filters

Refining Used Lubricating Oils describes the properties of used lubricating oils and presents ways these materials can be re-refined and converted into useful lubricants as well as other products.

Pour point, density, viscosity index, and total acid number of used engine oil and re-refined oils were measured in order to evaluate the two re-refining processes used and assess whether it is

Analysis and comparison of used lubricants, regenerative ..

- Usage: Cooking Oil

- Model number: TN-100L

- Application: Liquid, hemp, herb, Cooking oil, vegetable oil extraction

- Weight (KG): 1580 KG

- Main components: Motor

- Material: Stainless Steel 304 316

- Working pressure: Atm., vacuum, positive pressure

- Solvent: Water, ethanol or others

- Capacity: 50L-500L

- Composition: Extractor, concentrator, precipitation tank, storage tank

- Local service location: States United

The re-refining of used lubricants is used when they contain high concentrations of contaminants. This process yields by-products that find their use as fuel. Thus, the re-refining processes used for the treatment of used lubricants have a marked influence on the pollutants concentration and the applied product quality ( Guerin, 2008 ).

Waste lubricating oil is considered to be a hazardous waste and has tremendous impact on human health and environment. The present review elaborates on the lubricant demand and market share.

Ivory Coast’s SIR Oil Refinery receives $660 million loan ..

- Usage: Edible Oil

- Capacity: 30-40 kg/h

- Voltage: 380 V

- Dimension (L*W*H): 1000*750*1200 mm

- Weight: 230 KG

- Main components: motor, pressure vessel, pump, others, gears, bearings, motor, gearbox

- Oil type: cooking oil

- Machine name: Thailand oil press machine small virgin cooking oil extractor machine

- Residual oil ratio: 6%

- Material: carbon steel and stainless steel

- squeezer diameter: 125mm

- Function: kitchen price rapeseed oil extractor machine oil press expeller

- Post-warranty service: video technical support

By Anine Kilian, Contributing Editor. The development finance institution Africa Finance Corporation has closed a $660 million debt financing loan for Société Ivoirienne de Raffinage of C?te d’Ivoire (SIR), the largest in French-speaking oil refinery in West Africa.

The product produced after the re-refining of used oil is known as re-refined base oil (RRBO), which has similar properties to virgin base oils (VBO) and hence can be blended with VBO in certain proportions, say a minimum of 25%. The re-refining of used lubricants results in environmental and economic benefits.

Overview on globally applied used engine oil recycling ..

- Usage: Edible Oil

- Capacity: 60-400 kg/h

- Voltage: Customizable

- Dimension (L*W*H): 1800*1200*1550 mm

- Weight: 1100 KG

- Warranty: 1 year, 12 months

- Main components: engine, motor

- Oil type: cooking oil

- Advantage: energy saving and simple operation

- Material: 304 stainless steel

- Function: Making edible oil

- Color: Blue

- Application: Oil pressing

- Raw material: Sunflower

- Product name: Kitchen oil presser oil cold press machine

- Feature: High oil performance efficiency

- Quality: Top level

In the developed country, where strict rules against illegal disposal are adopted, recycling and re-refining of used engine oil are common phenomena (Ra?iu et al., 2022).

Advancing sustainable lubricating oil management: Re-refining ..

- Usage: Edible Oil

- Capacity: 5-600 kg/h

- Voltage: 220 V/380 V

- Dimension (L*W*H): 420*200* 360mm

- Weight: 35KG

- Warranty: 1 year, 1 year oil press machine with backing

- Main components: motor, pressure vessel, pump , gear, bearing, motor

- Oil type: Cooking Oil

- Total power: 4000W

- Raw material: Cooking, pine, Cooking

- Name: Oil press processing equipment

- Capacity: 150kg/hour

- Used for: Extrusion oil

- Oil rate: 96%

- Package: Wooden box

- Voltage: 220v

The primary aim of this paper is to elucidate various techniques for re-refining used lubricating oil, including the acid/clay method with and without clay activation, solvent extraction, hydrotreating, and pyrolysis, while comparing the physical and chemical properties of the treated samples to those of fresh lubricant oil samples.

- What is lubricating oil re-fining?

- Re-fining is the use of distilling or refining processes on used lubrication oil to produce high quality base stock for lubricants or other petroleum products. The use of this method has increased tremendously in developed countries, some countries reaching up to 50% of the country’s need for lubricating oil .

- What are lubricants used for?

- One of its important applications includes gasoline and diesel engine oils . Typically lubricants contain 90% base oil (most often petroleum fractions, called mineral oils) and less than 10% additives. A large number of additives are used to impart performance characteristics to the lubricants. The main families of additives are:

- What is used lubricating oil?

- Used lubricating oil Used lube oil is defined as the petroleum derived or synthetic oil which remains after applications in lubrications, cutting purposes, etc. After a certain period of useful life, the lubricating oil loses its properties and cannot be used as such in machinery.

- How can lubricating oil be recycled?

- The recycling of waste lubricating oils can be accomplished through three basic methods, which are reprocessing, re-refining and destruction. Re-fining is the use of distilling or refining processes on used lubrication oil to produce high quality base stock for lubricants or other petroleum products.

- Does used lubricating oil pollute water?

- Re-refining of used lubricating oil. Abstract - Small amount pure lubricating oil can pollute major amounts of water eg: groundwater as well as the land on which it is spilled. Used engine oil itself contains a number of additives and is contaminated by impurities and residues resulting from the combustion process.

- What is waste lubricating oil?

- Waste lubricating oil is a resource that cannot be disposed of randomly due to the presence of pollutants. In response to economic problems and environmental protection, there is a growing trend to regenerate and reuse waste lubricants. By proper recovery and refinement of it, a lot of valuable product can be obtained.