Ideal extruder temperature to produce best full fat soybean meal

- Usage: Cooking Oil

- Capacity: 5TPD-100TPD, 1-1000t/d

- Voltage: 220V/380V

- Dimension (L*W*H): 1700*1300 *1600

- Weight: 700kg

- Certification: ISO CE

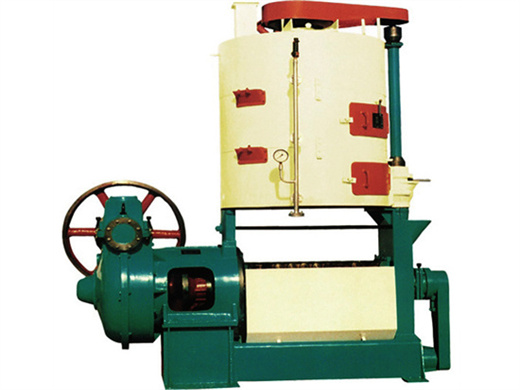

- Name: Good prices of Cooking oil mill machinery for cooking Oil mill

- Proportion of residual oil: 1%

- Advantage: high oil yield

- Machine color: Blue Customized

- Machine material: Carbon Steel; Stainless steel

- Keyword 2: Good prices for oil mill machinery

In addition, there is a lack of clarity amongst many extruder operators on the optimum processing conditions for obtaining the best quality of this potential feed ingredient. BENEFITS OF FULL FAT SOYBEAN MEAL According to Ramos (2021), FFSBM is an excellent source of energy with high stability on fat.

We can see a few things right away. Dry extruded whole soybeans, with all of the oil still in the meal, have a lower total protein content. Despite having a slightly higher overall amino acid digestibility value (all averaged together), the amino acid supply from dry extruded whole soybeans will always be lower than other partially- or fully-deoiled soy meals, like solvent-extracted.

Why Extrude Soybeans? l Benefits of Soybean Extrusion Insta-Pro

- Usage: Edible Oil

- Model number: GLZL-200

- Voltage: 220v

- Power (W): 0.75k

- Weight: 260kg

- Dimension (length x width x height): 1100*400*1100 mm

- material: stainless steel

- used for: peeling red skin of peanuts

- peanut skin peeling machine method: dry peanut skin peeling machine effective: peanut skin peeling machine capacity

- in whole grain: Peanut skin peeling machine 200kg /time

- suitable for: roasted peanuts

Insta-Pro developed and patented high shear extrusion in the late 1960’s to provide farmers with the opportunity to obtain the full value of feeding their home grown soybeans to their animals. Based on animal performance data, the benefit of our dry extrusion technique has proven to be the most effective way of processing soybeans to reduce

Capacity from 500 Kg to 2000 Kg per hour. Used to extrude full fat soya. Heat up the raw material before pressing the oil. Increases the amount of oil during pressing in presses.

Full Fat Soya Extruder Efficient Animal Feed Processing

- Usage: Cooking Oil

- Capacity: 400kg/h

- Voltage: 220v

- Dimension (L*W*H): 320*150*350mm

- Weight: 6,600kg

- Function: Edible oil manufacturing

- Raw material: soybeans, sesame, peanuts

- Application: Oil production line

- Heating type: Heating tube

- Temperature control: Temperature sensor keeps machine cool

- Material: 304 stainless steel

- Feature: High oil performance efficiency

Full Fat Soya Bean Extruder Machine/Extruder soybean soya production line floating fish feed pellet extruder. $1,300.00-1,380.00. Min. Order: 1 unit. Previous slide

MS 3000 Extruder. The MS3000, Medium Shear Extruder, is designed for processing textured and shaped products, like textured soy protein. The extruder combined with proper preconditioning allows for flow conditions within the barrel that enhances the final product shape. Features: Ideal for small- to medium-volume applications

Extruders & Oil Presses For Feed Ingredient Processing

- Usage: Edible Oil

- Capacity: 5t/d to 1000t/d

- Voltage: 220V/380V/440V

- Power (W): According to different capacities

- Dimension (L*W*H): 1200*400*900mm3

- Weight: According to different capacities

- Certification: CE

- application: all kinds of seeds can produce oil

- color: blue/green and others

- capacity: 3t to 800t /d

- warranty: one year

- durability: 20 years

- main market: Asia/Europe/Africa/South America

- After-sales service: workshop design/installation/worker training

- functions: mainly used to make cooking oil

- payment: T/TL/ C and west junction construction design: available

Insta-Pro International uses precision engineering & groundbreaking nutritional research to develop precision-crafted extrusion systems. The result: chemical-free, nutrient-dense feed & food products.

Full Fat Soya Extruder Machine Soybean Extruder

- Usage: Cooking Oil

- Capacity: 100% cooking shelling machine

- Voltage: 220V/380V/440V

- li> Power (W): Depends on its capacity

- Dimension (L*W* H): Depends on its capacity

- Weight: Depends on its capacity

- Certification: CE/BV/ISO9001

- Raw material: Vegetable seed

- Name: cooking hulling machine

- Application: cooking oil pressing

- Common capacity: 1-2000TPD

- Character: semi-automaticAfter-sales service: installation, debugging, training and service

- Certificate: CE /BV/ISO9001

- Advantage: energy saving/high oil yield

- Flow chat: cold pressing/hot pressing/pre-pressing

Product Show. Our Services. Packaging & Shipping. Company Information. Henan Double Elephants Machinery I/E CO.,LTD. A professional collection of research, design, production and sales of Oil making machine,animal food machine, extruder machine for pet and snacks,and many other kind of food machine.

- What is soybean extrusion?

- Extrusion with humidity up to 12%. The raw material is processed in the extruder for no more than 30 seconds. Therefore, both proteins and fats in soybeans retain their nutritional qualities. Raw material is fed into the working body of the extruder by a screw feeder (with frequency control of speed)

- Does solvent extruded soybean meal have a lower protein content?

- Values for samples of commodity, solvent-extracted soybean meal, which were recently analyzed, are shown for comparison. We can see a few things right away. Dry extruded whole soybeans, with all of the oil still in the meal, have a lower total protein content.

- How is soybean oil extracted?

- Prior to the mechanical extraction of oil, soybean is processed inside the extrude barrel, the soybeans are being compressed, ground and heated that frees the oil by rupturing oil seed cell walls. Due to dry extrusion the fat cells open and as a result fats are easily digested by domestic animal. Steel Fabricated Base & Bodies. Low Maintenance.

- Can you use dry extruded whole soy in a broiler formulation?

- I put together some estimations for a colleague in another part of the world regarding how to think about using dry extruded whole soy in an example broiler formulation. Dry extruded soy meal adds $51 per metric ton to a formulation over the cost of solvent-extracted soybean meal.

- Does dry extruded whole soybean have a lower protein content?

- Dry extruded whole soybeans, with all of the oil still in the meal, have a lower total protein content. Despite having a slightly higher overall amino acid digestibility value (all averaged together), the amino acid supply from dry extruded whole soybeans will always be lower than other partially- or fully-deoiled soy meals, like solvent-extracted.

- What are lab tests for raw soybeans & extruded ffsbm?

- Common lab tests for raw soybeans and extruded FFSBM included crude protein (CP) content analysis and other tests for measuring FFSBM quality. These included official methods (Palic et al., 2008) – urease index (UI) and protein dispersibility index (PDI) and unofficial methods like KOH protein solubility (PS) and trypsin inhibitor (TI) activity.