How to extract castor oil from castor seeds

- Usage: Cooking Oil

- Automatic grade: Semi-automatic

- Capacity: 1TPD-1000TPD

- Voltage: 220V

- Power (W): 5.5 kW

- Dimension (L*W*H): 46*32*36 cm

- Weight: 130 kg

- Certification: ISO9001

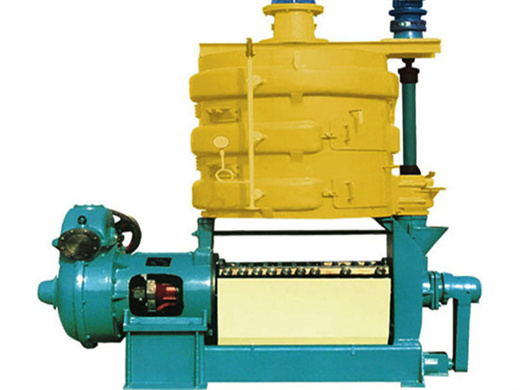

- Product name: small cooking oil making squeezing machine for sale

- Item: Vertical oil press

- Advantage: Energy Saving

- Warranty: One Year

- Function: Hot Press

- Feature: Multifunction

- Product: Oil Scope

- Section: Pre-pressing section

- Application: Oil production line

- Use for: Vege

Castor seed is grown commercially on plantations but also harvested from wild plants.The seed must be hulled after harvesting.This can be done laboriously by hand or, more commonly,by machine.Small-scale hand-operated dehullers are available.But how to extract castor oil from castor seeds?The castor oil extraction plant is necessary.The

The first stage of oil extraction is pre-pressing, normally using a high pressure continuous screw press called the expeller. Extracted oil is filtered, and the material removed from the oil is fed back into the stream along with fresh material. Material finally discharged from the press, called castor cake, contains 8-10% oil. It is

How to Setup a Manufacturing Plant of Castor Oil

- Usage: Edible Oil

- Capacity: 1tpd-30tpd

- Voltage: Design according to customer demand

- Power ( W): 11 KW

- Dimension(L*W*H) : 4935*1523*2664

- Weight: Standard

- Production Material: Stainless steel or carbon steel

- Raw material: Suitable for oil Cooking seeds and others

- Export markets: Europe, Southeast Asia, Africa, etc

- Working principle : mechanical extrusion

- Warranty period: one year

- Used for: oil extraction machine for making red Cooking oil

10. Revenue Potential For Manufacturing Plant of Castor Oil. Yield: ~35?45% oil by weight of castor seeds. 1 tonne of seeds produces 350?450 liters of oil. Selling Price: Crude Castor Oil: ?100??150 per liter. Refined Castor Oil: ?200??400 per liter. For a 5-tonne/day plant: Daily Output: ~1,750 liters of crude oil.

Each of these steps is essential in the seed preparation process to ensure the extraction of high-quality castor oil. Oil Extraction. Efficient oil extraction from castor seeds involves a meticulous process of seed roasting and pressing to maximize the yield of high-quality castor oil. The first step is seed roasting, where the seeds are heated

Leading Cold Castor Oil Machine Castor Seed Oil Extraction Machine

- usage: To Extract Oil From Various Oilseeds & Nuts.

- Capacity: 1-1000TPD

- Voltage: 220V/380V/415V

- Power ( W): 1-30kw

- Dimension (L *W*H): According to capacity

- Weight: According to actual situation

- Certification: ISO9001

- Keywords: Vegetable oil refining machine

- Raw material: Vegetable seed

- Advantage: energy saving and environmental protection

- Strength of supplier : with 30 years experience

- Machine material: stainless steel and carbon steel part

- Color: according to customer's requirements

- Residual: Less 2%

- Supplier: Group factory

- Product name: vegetable oil refining machine

High oil yield compared with traditional equipment, the normal oil yield of a castor oil extractor can be 2 to 3 percentage points higher, and the economic benefits are higher. Energy-saving among the oil press with the same output, the castor oil press machine reduces the electric power by 40%.

Several problems are associated with the existing castor oil extraction methods, specifically the traditional techniques, quantity, quality, and time of production. This study designed and built an energy-efficient and high-quality castor seed oil extraction machine using the continuous screw method and revolving screens for enhancing quantity and

Made Castor Seeds Oil Press Plant Castor Seeds in Ivory Coast

- Usage: Cooking Oil

- Capacity: 100-500 tpd vegetable oil making

- Voltage: 220V/380 V/440 V

- Power (W): depends on capacity

- Dimension (L*W*H): 5432*2636*2345

- Weight: 850 KG

- Certification: ISO9001

- After-sales service provided: Overseas service center available

- Keywords: vegetable oil making machines

- Name: Vegetable Oil Making

- Material: Stainless Steel

- Engineers Request: 1-2 Engineers

- Oil Grade: 1st , 2nd, 3rd

- Environmentally friendly: yes

- Business type: manufacturer

- Methods: oil making machines

- oil rate: 20%-98%

Castor seeds contain 45 50 % oil content. After two stage pressing, about 8 % residual oil is left in the oilcake/meal. The castor seeds are conditioned using Steam in a Cooking Kettle. Castor seed oil processing by-products are suitable raw materials for biogas and bioethanol production . Bio-oil from castor seed cake was produced through

castor seeds oil extraction equipment in ivory coast

- Usage: Cooking Oil

- Capacity: 10T~20TPD

- Power (W): according capacity

- Dimension (L*W*H): 5432* 2636*2345

- Weight: 2000 kg

- Application: various crude oils such as sunflower oil, oil

- Ways of operation: safe and simple

- Commercial oil grade: high

- Cultivation Processing Refining technique: batch and semi-continuous

- Humidity and volatiles: 0.08%

castor seeds oil extraction equipment in ivory coast Machine Type: castor oil extraction equipment; Production Capacity:50-1000TPD; Dimension(L*W*H): biodiesel production plant; press power: 1500w; Certification: ISO, IFOAM & Etc; Continuous working time: 150H; Raw Material: castor; Market: ivory coast

- How to extract castor seeds?

- Currently used extraction techniques are supercritical fluid, pulsed electric field, Soxhlet, enzyme-assisted extraction, ultrasound, and microwave-assisted extraction. These methods are efficient and result in rapid extract recovery. Castor seeds are one of the most produced non-edible oil crops in India.

- Which extraction method provides the highest yield of castor oil?

- The hybrid ultrasound-microwave-assisted extraction provided the highest oil yield, whereas supercritical CO 2 extraction showed no effect. The composition and properties of castor oil depend on not only extraction methods but also geographical origin, climate, soil, cultivar, and harvest time.

- Is Castor a viable seed oil extraction method?

- Castor is one of the essential seed crops. Demand for increasing vegetable oils (edible and non-edible) necessitates developing cost-effective, sustainable, environmentally friendly, and industrially viable seed oil extraction techniques that produce high extraction yield with minimal impact on bioactive quality.

- Can a hybrid method be used to extract oil from castor?

- The hybrid method by applying synergetic effect of ultrasound and microwave for in-situ oil extraction from large scale non-edible oil feedstocks such as Castor, hasn't been looked into as much as conventional techniques and other methods like individual ultrasound and microwave.

- How does hybrid intensification improve castor oil extraction yield?

- Hybrid intensification (ultrasound and microwave) increased castor oil extraction yield by 20%. Energy consumption is reduced by up to 40% compared to the conventional mechanical stirring technique. Omega-6 fatty acid composition is increased in the oil extracted through the hybrid technique.

- What makes castor oil a good biorefinery?

- The composition and properties of castor oil depend on not only extraction methods but also geographical origin, climate, soil, cultivar, and harvest time. The future perspective involves utilizing the entire biomass in a biorefinery to maximize the value of oil, seed cake, and waste residues.