Soybean Milling RMS Roller-Grinder

- Usage: Edible Oil

- Capacity: 800 KG/H

- Voltage: 380 V/50 HZ

- Dimension (L*W*H): 2670 *1000*1726mm

- Weight: 1800kg

- Main components warranty: 3 years

- Main components: pressure vessel, motor, gearbox

- Material: stainless steel, carbon steel and iron

- Color: Green, blue, gold, gray, can be customized

- Advantage: High efficiency

- Point Sale: Healthy and high performance

- Application range: Cooking, dry oil seed

- Character: large capacity

- Simultaneous application: oil processing line edible

- Post-warranty service: Spare parts

- Certification: ISO

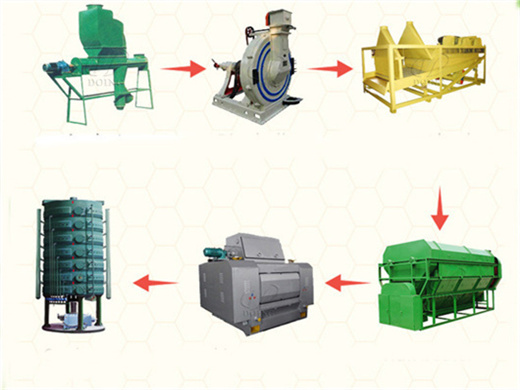

Many companies in the soybean processing industry struggle to meet demand while reducing waste and producing the best possible product. Types of Soybean Processing. There are a few types of soybean processing. The two primary aspects of soybean processing include removing the hull and extracting protein from the inside of the bean.

The main products include screw oil presses, solvent extraction equipment, refining equipment, etc., covering the complete production chain from soybean pretreatment, oil pressing to oil refining. The equipment design adopts advanced automatic control system, which is easy to operate and has the characteristics of high output, low energy

SOYBEAN PROCESSING EQUIPMENT bronto

- Usage: Cooking Oil

- Capacity: 1-2000TPH

- Voltage: 220V/380V

- Power (W) : 18.5 KW

- Dimension (L*W*H): 2000x1400x1850mm

- Weight: 1200kg

- available material: machinery for grinding oil from fruit clusters Cooking

- texture: stainless steel, carbon steel, alloy steel

- projects carried out: complete oil lines 1-2000TPD

- >markets: America, Europe , Africa, Asia, Australia

- services: engineering, production, installation, construction

- Advantage: energy saving, environmentally friendly

production of soybean oil . The processing line copes with the following processes: soybeans dehulling or decortication, soy grinding, mixing and heating up due to high pressure, high shear and temperature, decreasing of trypsin inhibitor and urease activity, pressing out the oil from the full fat soybean.

The extrusion and cooking of beans are essential in soybean processing facilities. Yemmak’s soybean extruder helps cook soybeans without affecting their protein quality and improve their digestibility. "We produce turnkey solutions for soybean processing facilities with our extensive experience and high quality standards."

project for production of soybean oil in jakarta

- Usage: Cooking Oil

- Capacity: 1t/day-1t/hour-100%

- Voltage: 220V/50HZ three-phase

- Dimension (L *W*H): 1055 *805*345mm

- Weight: 27.1 KG

- Main components: motor, motor

- Oil type: cooking oil

- Name: cooking oil milling machine production line

- Advantage: High oil yield

- Character: Easy to move

- Function: Oil pressing

- Color: Customer Required

- Quality: High Level

- Operation: Easily

- Keyword: Oil Solvent Extraction Equipment kitchen

- Model: TS-BXG-128

project for production of soybean oil in jakarta . Automatic Grade: Semi-automatic; Production Capacity: 30kg/h; Voltage: 220V; Dimension(L*W*H): 420*200*360mm

IMARC Group’s report titled “Soya Bean Processing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue” provides a complete roadmap for setting up a soya bean processing plant. It covers a comprehensive market overview to micro-level information such as unit

Bean processing equipment, soybean processing machine ..

- usage: To Extract Oil From Various Oilseeds & Nuts.

- Capacity: 50T~100T/D

- Voltage: 220V/380V

- Power ( W): According to capacity

- Dimension (L*W*H): 430*230*350

- Weight: 1050 KG

- After-sales service: Yes

- Mixed oil concentration: 18-25%

- Commercial solvent residual: < 0.07%

- Market: all countries

- Crude oil index: 50-500ppm

- Main equipment: rotocel extractor, conveyor, desolventizer

- Material: Stainless steel and carbon steel

- >Extraction method: solvent extraction method

Win Tone provides bean processing enterprises with complete sets of bean processing equipment and technology, with complete equipment models and favorable prices. Grain and Pulses Cleaning Plant Capacity: Processing 5-20 tons of raw beans Finished Product: Various clean beans and grains

Soybean Rice Grinding & Separating Machine (Soya Grinder ..

- Usage: Edible Oil

- Capacity: 5TPD-100TPD

- Voltage: 380v

- Dimension (L*W*H): 2100*1500*1800mm

- Weight: 1200 KG

- Warranty: 1 year, 12 months

- Main components: motor, cooking oil making machine

- Oil type: cooking oil kitchen

- Material: Alloy steel, stainless steel

- Name: Cooking oil processing machine

- Features: High efficiency, low cost

- Capacity: 300~500 kg/h

- Used for: Commercial oil expeller

- Advantage: High oil yield

- Range Application: Prickly pear oil pressing machine

- Raw material: Vegetable seed

- Keyword 1: Pressing machine for oil production

Soybean and Rice Grinding and Separating Machine. 1. The major difference in various types of the Soybean Rice Grinding & Separating Machine Series Type M-18 is a mini Tofu and soy milk making machine.

- What is the process of processing soybeans?

- Processing soybeans can include crushing, milling, or de-hulling. Crushing soybeans is typically used to produce oil, while milling is used to make soybean meal as a protein source. Dehulling soybeans is necessary for the processing of soybeans in any form, and is needed to create a consistent particle size during the milling process.

- What are the two main aspects of soybean processing?

- The two primary aspects of soybean processing include removing the hull and extracting protein from the inside of the bean. The protein can then be used to make a wide range of soy products and agricultural feeds for various industries. Processing soybeans can include crushing, milling, or de-hulling.

- What is soybean milling?

- Soybean milling is the process of taking whole soybeans and processing them into a usable product: soybean meal. Processing soybeans typically involves de-hulling soybeans and then crushing or cracking them so they can be used for a wide range of applications. Although soybean milling is a common practice, not every milling method is optimal.

- Why should you choose RMS for your soybean milling process?

- With RMS, you have a partner to support your soybean milling processes with systems tailored to your unique needs. Let our experienced team and industry-leading equipment help your company grow just as the soybean industry is growing!