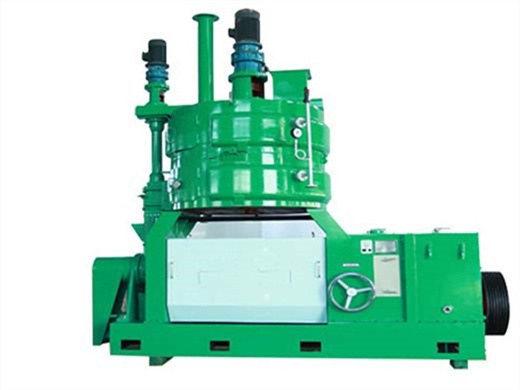

High-Efficiency Sunflower Oil Making Machine QI'E Group

- Usage: Edible Oil

- Model number: GL

- Application: roti

- Voltage: 220V/380V

- Power (W): 1.6 -16 kw

- Weight: 90-180 kg, 90-180 kg

- Dimension (L*W*H): 520*620*1350

- Material : Stainless Steel

- Model: GL

- Capacity: 400-800pieces/h

- Power: 1.6-16kw

- Dimension: Depending on model

- Production time: 10-15 working days

- Warranty: 1 year, excluding wearing parts

- Delivery: By sea transport

The sunflower oil making machine launched by QI'E Group is perfectly suitable for small and medium-sized oil processing enterprises. It has the advantages of high efficiency, energy saving and multi-function, which can take your oil processing to a higher level.

Including Oil Pressing Machinery oil production equipment, complete sets of edible oil refining equipment, etc., it has an efficient and environmentally friendly product line and has long enjoyed a high reputation in the domestic and foreign markets.Our products are exported to more than 120 countries.

Setup Edible Cooking Oil Production Plant with QIYI Machinery ..

- Usage: Cooking Oil

- Voltage: 220 V/380 V

- Power (W): according to capacity

- Dimension (L*W* H): 100*100*12m

- Weight: related to capacity

- Certification: ISO9001

- Production Business type: Manufacturer

- Accepted delivery terms: FOB, CFR, CIF, EXW

- Guarantee:

- Packaging: Wooden package

- Suitable objects: Girasoletc.

- After-sales service: Yes

15TPD Sunflower Oil Manufacturing Plant Setup in Uzbekistan 50TPD Corn Oil Extraction Plant and 15TPD Oil Refinery Line in Iran Small Soybean Oil Production Machine & Plant Installed in Nigeria >20TPD Oil Refinery Plant Project Coconut Oil Refining Process Expert Tips for smart investment High-Effect Rice Bran Oil Refining Process Low-Cost

Plant & Machinery We filter the world excellent We are specialized in the manufacturing installation erection and commissioning of edible oil project from seed preparation to final quality of cooking oil with the bay product of meal extracted from seed either canola or soybean.

Set Up Edible Oil Plant in Pakistan- Great Market Potential

- Usage: Edible Oil

- Capacity: 1TPD-1000TPD

- Voltage: 380V

- Power (W ): according to capacity

- Dimension (L*W*H): various with capacity

- Weight: changed with capacity

- Certification: CE and ISO

- Raw material: Vegetable seed

- Product: Miller crude cooking oil machine extractor

- Solvent name: n-hexane

- Capacity: 1-3000TPD cooking oil extraction machine

- Oil content in sunflower: 18-22%

- Oil residue: less than 1%

- Function: cooking oil extractor machine

- Manufacturing experience: 40 years

- Equipment material: stainless steel and carbon steel

Requirements for Small oil Mills: There are many oil processing machinery in the market, based on the seed specifications the type of equipment are n in the process. But without the oil press machine, the extraction of the oil from the machine is impossible. Other notable machineries: Screw Oil Expeller: Main equipment in mini oil mills. It

We can provide edible oil refining plant equipment with capacity ranging from 50 t/d to 4,000 t/d for soybean oil, rapeseed oil, sunflower seed oil, cottonseed oil, rice bran oil, palm oil, corn oil, peanut oil, linseed oil, animal fats and oils, chicken fat, butter, fish oil and etc. Refining is the last step in edible oil processing.

Oil Extraction Machines Complete Guide

- usage: To Extract Oil From Various Oilseeds & Nuts.

- Capacity: 50 -3000TPD

- Voltage: 380v 440v

- Power (W): As production daily sunflower oil machine for cooking

- Dimension (L*W*H)): According to your daily production

- Weight: Depends on the production

- Material: stainless steel

- Application: for extraction of all seeds

- Residual oil in flour: less than 1%

- Solvent consumption: less than 2 kg/t

- Energy consumption: no more than 15 KWh/T

- Refining process: degumming, discoloration

- Sunflower extraction rate: 38% -42 %

- Payment: l/ct/t

Apr. 24, 2022. Screw oil press machine advantage. High degree of automation, Oil press and oil filter integration. Qifeng brand 6yl series new oil press machine is the earliest fully automatic oil press developed in China, integrating oil pressing and oil filtration, fully automated and easy operation, reducing labor intensity and improving work efficiency.

Oil processing equipments of oil mill plant

- Usage: Cooking Oil

- Capacity: 150-200 kg/h

- Voltage: 220 V/380 V

- Dimension (L*W*H): 1675*1000 * 1610mm3

- Weight: 730 KG

- Main components: motor, pressure vessel, pump, PLC, gear, bearing, motor

- Oil type: oil Cooking

- Color: blue, customize

- Material: Carbon

- Raw material: Cooking,Cotton,Tea

- Advantage: Automatic temperature control

- pressing power: (7.5-11kw)-6p

- Main shaft heating power: 1.8kw-220v

- pressing cage heating power: 0.8kw-220v

- After warranty service: video technical support, online support, spare parts

- Local service location: India

- Certification: CE

Here in the oil milling plant, hot pressing means cooking the oil seeds with a hot pressing machine before pressing in order to extract more oil. All main parts of hot pressing machine such as the worm shaft, pressing worms, cage bars and gears are made of high-grade alloy steel that have undergone hardening treatment.

- Can Papua New Guinea still produce oil and gas?

- Papua New Guinea can still be successful in producing oil and gas well into the future, but it has to learn that it takes more than oil and gas reserves to create a viable and sustainable production industry. A review of its past successes should indicate what it needs to do.

- Why did Papua New Guinea explorers invest in oil?

- With diminishing oil production and the absence of new oil finds, Papua New Guinea’s explorers needed to capitalise on prior exploration investments that failed to find oil. Gas in the new century was no longer a hindrance and could be profitably developed even extending the life of the oil fields.

- Why did Chevron leave Papua New Guinea?

- With Kutubu oil production declining, Chevron departed the venture, selling its Papua New Guinea interests to Oil Search and over the course of several years, the schemes waxed and waned.

- How did Exxon & BP develop LNG in Papua New Guinea?

- With the foundations for the gas development defined by the revised gas regulatory and fiscal regime, Exxon and BP pursued their LNG development plans based on the large Hides gas field with notions of taking the gas to the Papua New Guinea north-coast and a deep water plant site at Madang.

- Why did Papua New Guinea become an LNG exporter?

- And so, in May 2014, Papua New Guinea became an LNG exporter, and is now producing about 8+ mta LNG per annum to customers in China, Japan and Taiwan - well above the original nameplate capacity of the LNG Plant. It got there because of fine operatorship on the part of ExxonMobil of a coherent joint venture.

- How much LNG can Papua produce a year?

- With the combined processing capacity of the ExxonMobil-led PNG LNG Project (8.3 million tonnes per year) and the TotalEnergies-led Papua LNG Project (4 million tonnes per year), there will be an aggregate capacity to process 13.7 million tonnes of LNG per year (equivalent to about 300,000 barrels of oil per day).