Choosing the Right Press Brake: Here’s What You Need to Know

- Usage: Cooking Oil

- Capacity: 1tpd

- Voltage: 380v

- Dimension (L*W*H): according to capacity

- Weight: 300000 KG

- Main components: motor, pump

- Oil type: cooking oil

- Product name: animal fat melting machines

- Raw material: carbon steel and stainless steel

- Function: melting animal fat

- Application: food oil plants and food industry

- Advantage: Energy saving Low waste

- Character: Professional manufacturer

Pneumatic Press Brakes replace oil cylinders with compressed air, which can provide a high bending force necessary for most materials (no risk of fluid leakage, lower bending prowess) Press Brake Configurations. As for press brake configurations, there are two specialized configurations that can be useful for niche applications.

Press brakes are essential tools in metalworking, allowing for precise bending and shaping of various materials. To ensure the smooth operation of press brakes, it is crucial to use the right hydraulic oil. Hydraulic oil plays a vital role in lubricating and cooling the hydraulic system, preventing wear and tear, and maximizing the efficiency of the press brake. In this article, I'll discuss the i

Press Brake Hydraulic Oil Understanding ADH Machine Tool

- Usage: Cooking Oil

- Capacity: 5TPD-100TPD

- Voltage: 220V/50HZ three-phase

- Dimension (L*W*H)): 1055*805*345mm

- Weight: 27.1 KG

- Warranty: 1 year, 1 year

- Main components: Engine, Engine

- Oil type: Oil kitchen

- Name: oilseed extruder

- Advantage: High oil yield

- Character: Easy to move

- Function: Pressing of oil

- Color: Customer required

- Quality: High level

- Operation: Easily

- Keyword: Oil solvent extraction equipment kitchen

- Model: TS-BXG-128

II. The Role of Hydraulic Oil in Press Brakes. Hydraulic oil plays an essential role in CNC press brakes. The hydraulic system is the core of the CNC press brake. It transforms the power via hydraulic oil, thus driving the various parts of the machine. The main function of hydraulic oil is to pass through the power, lubricate, and seal.

Locate the hydraulic oil filling port on the hydraulic press brake. Typically, the filling port is located above the hydraulic oil tank of the equipment. Refer to the press brake user manual or the service personnel's guidance to ensure that the correct filling port is found.

7 Types Of Industrial Metal Bending Machine MYT CNC

- Usage: Cooking Oil

- Capacity: 500

- Voltage: 380

- Dimension (L*W*H): 6000X5000X5000

- Weight: 12000 KG

- Warranty: 3 years

- Main components: Pressure container, Pump

- Oil type: Cooking oil

- Product name: extraction machine

- Name: Oil Extraction Machine

- Function: Oil Extraction Machine

- Extraction Type: Super Critical CO2 Fluid Extraction

- Material: SUS304

- Capacity: 50-1000 kg/h

- Process: Co2

The sheet metal press brake is one of the most well-known types of metal bending machines and is therefore sometimes simply referred to as a bending machine. The machine works by clamping a metal sheet between an upper die (punch) and a lower die, applying pressure to deform the sheet into the desired shape.

On the other hand, it is not suitable for bending thick plates or high-precision bending. Torque Press brake torque is the bending force applied between the punch and die. Torque varies depending on the thickness and hardness of the plate to be bent, the bending angle, the bending width, etc. Press brake torque is generally classified as follows.

Hydraulic Press Brake Safety & Maintenance: Expert Tips

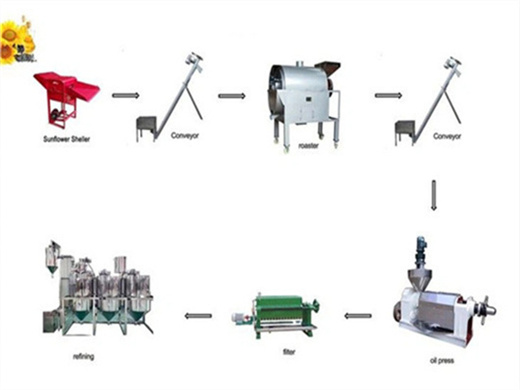

- usage: To Extract Oil From Various Oilseeds & Nuts.

- Product name: Flower oil extraction machine

- Advantage: Easy operation

- Can be customized: Yes

- Quality: International upper

- Weight: Its capacity will tarnish

- Material: Stainless Steel

- Capacity: 10L-55L

- Certification: ISO, CE

- Function: Distillation of Cooking Oils

- Transport Package: by Express

- Specification: 90 *50*65 CM (depends on capacity)

- HS code: 8419409090

- Capacity: 10000

How do you ensure a hydraulic press brake remains safe and efficient? This article covers essential safety protocols and maintenance tips, including pre-operation checks, proper handling during use, and routine upkeep of hydraulic systems. By following these guidelines, you can prevent accidents and extend the lifespan of your equipment.

Ensuring Bending Precision: The Role of Press Brake ..

- Usage: Cooking Oil

- Capacity: 500-800 kg/h

- Voltage: 380V440V

- Dimension (L*W*H): 1750*1150*1720mm

- Weight: 650 KG

- Main components warranty: 2 years

- Main components: motor, pressure vessel

- Oil cake: oil left in the cake is less than 6%

- Used for: Commercial oil expeller

- Pressing method: Screw squeezed Press

- Application range: Cotton seed, etc.

- Function: Oil pressing

- Application: Edible oil production

- Oilseed extraction: 90% oil yield

- Raw material: Sunflower seed

The Importance of Press Brake Maintenance for Precision. Press brakes are essential in the metal fabrication industry for their ability to bend and shape metal with high precision. However, without regular maintenance, even the most advanced press brakes can fall short of delivering the desired accuracy.