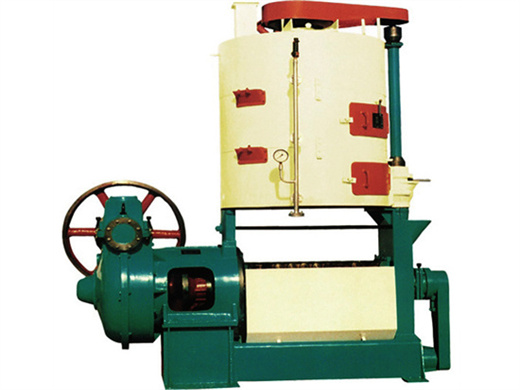

Screw Peanut Groundnut Oil Extraction Machine for Factory Use

- Usage: Peanut , Peanut oil, Peanut

- Type: Peanut , Peanut oil, Peanut oil

- Production Capacity: 30kg-30t/day

- Voltage: 380V or designed by your needs

- Power(W): Depend on the machine you choose

- Dimension(L*W*H): Depend on the machine you choose

- Weight: Depend on the machine you choose

- Item: Peanut oil pressing machines/hot pressed Peanut oil

- Supplier type: Manufacturer

- Manufacturing experience: 20 years

- Steel type: MiId steel and SS

- Raw materials: Peanut

- Fina product: Salad oil

- Processing method: Machanical press

- Handling capacity: according to custoemer design

- Model type: Continuous

This screw peanut oil extraction machine is an efficient and energy-saving oil processing equipment, which is widely used in the pressing of various oil crops such as peanuts, peanuts, sunflower seeds, etc. The equipment adopts advanced screw extrusion technology to extract oil from oil by physical pressing, which not only improves the oil

Step 4: Pressing. The peanuts are transfer by conveyor and fed through the hopper of screw press machine. Continuous transport of material by the screw shaft causes pressure to increase to a level needed, which increases friction inside the screw press and generates heat which lowers viscosity of the oil in the crushed seeds thereby increasing the oil flow rate.

3-5 Years Working Time Combined Oil Press Machine Auto Peanut Oil Press Mashin

- Usage: Peanut Oil

- Production Capacity: 150-250kg/h

- Voltage: 380v

- Power(W): 7.5kw

- Dimension(L*W*H): 1950*1300*1900

- Weight: 950kg

- Item: Peanut Oil Making Machine

- Color: Light yellow

- Productivity: 150-250kg/h

- Screw speed: 30-40 r/min

- Vacuum pump: Y90S-4-1.1Kw

- Weight(KG): 950

- Production cendtion: Staff1-2, plant 30m2-50m2

- Model: 6YL-100R

GOYUM GROUP is the largest groundnut oil extraction machine manufacturer and supplier in India. We are focused on providing the most advanced oil processing machines to help our customers reduce costs and improve oil production. We are offering groundnut oil extraction machine with different capacities.

Features of Groundnut Oil Processing Machine. The groundnut oil processing machines with multi-use, can be used to process both 1st press and Pre-press. From material feeding, cooking to produced oil, cake, all of processes are continuous working, easy management and labor saving. The groundnut oil processing machine is composed of main axes

Fully Automatic Groundnut/Peanut Oil Production Line

- Type: Melting furnace

- Usage: Melting Furnace

- Core Components: Engine, Motor

- Voltage: 380v

- Dimension(L*W*H): custom, customization

- Weight (T): 10 T

- Power (kW): 220

- Warranty: 1 Year, 1 year

- Product Name: gas fired rotary furnace

- Melting Material: metal scrap

- Function: melting metal scrap

- Material: copper scrap

- Raw material: brass, copper, pure aluminum

What parts are included in a peanut oil screw press? Peanut oil screw press mainly consists of five parts: hopper, gear box, press chamber, press screw and frame. Among them, the press screw is the key of the whole peanut oil screw press, and the choice of its material will affect the quality and service life of the press. 2024-08-26

However, the crude peanut oil usually contains a number of impurities. So for edible oil, the pressed groundnut oil needs to be extracted in the oil extraction plant before the extracted oils are sent to the oil refining plant for further processing. Groundnut oil pressing process:

Groundnut Oil Extraction Plant Peanut Oil Processing

- Usage: Peanut Oil, Peanut Oil seed

- Type: Oil Extraction Machine

- Production Capacity: More than 95%

- Voltage: 380V

- Dimension(L*W*H): 120*60*90CM

- Weight: 325 KG

- Core Components: Motor, PLC, Gearbox

- Oil type: Peanut Oil

- Product: Single oil press machine

- Production: 60-800 kg/h

- Motor power: 5.5 kw

- Advantage: single press, cold press

- Material: Iron+stainless Steel

- Package: Plywood box package

- Option: Oil pan, oil cover and hopper are all stainless steel

- Application: Peanut oil production line/Peanut oil production line

Groundnut decorticator machine is used to remove the hard shell of peanuts and get red skin peanut kernels automatically. The shelled peanut kernel can be applied to the peanut oil production line. Groundnut decorticator is versatile in shelling not only peanuts but other oil seeds like almonds, sunflower seeds.

Small Groundnut Oil Extraction Equipment Hot Cold Oil Press

- Usage: Peanut Oil, Cooking Oil

- Type: Peanut Oil Press Machine

- Production Capacity: 50-500kg/h

- Voltage: 220v/110V

- Dimension(L*W*H): 430*290*220mm

- Weight: 7.8 KG

- Core Components: Motor, PLC, Bearing

- Oil type: Peanut Oil

- Raw material: Peanut

- Product name: Home Small Oil Presser

- Function: Oil Mill Making Pressing Extracting Machine

- Application: Edible Oil Press

- Advantage: Automatic Temperature Control

- Feature: High Oil Yield Efficiency

Pretreatment and pressing section workflow of groundnut oil processing plant. Groundnut oil solvent extraction section. The groundnut oil solvent extraction plant is one of the most important equipment in the groundnut oil mill plant. Generally, by using the extraction way, the oil residue will be lower than 1%.

- What is groundnut oil manufacturing process?

- Groundnut oil manufacturing process is divided into two methods, the first is mechanical pressing and the second is solvent extraction. Mechanical pressing can extract 85% oil and the remaining oil is extracted by the solvent extraction method.

- How to make peanut oil from groundnuts?

- According to mechanical pressing technology, you can divide the peanut oil production process into three phases. These are peanuts preparation, pressing and crude oil refining. Step 1: Cleaning Step 2: Dehulling Step 3: Cooking Step 4: Pressing Step 5: Filtration After harvesting groundnut are received at processing facilities.

- What is peanut oil production process?

- The peanut oil production process involves peanut preparation, pressing and crude oil refining.

- How is peanut oil extracted?

- Mechanical pressing can extract 85% oil and the remaining oil is extracted by the solvent extraction method. According to mechanical pressing technology, you can divide the peanut oil production process into three phases. These are peanuts preparation, pressing and crude oil refining. Step 1: Cleaning Step 2: Dehulling Step 3: Cooking

- Why do we use a cleaning machine for peanut extraction?

- Batches of harvested peanuts will contain whole peanuts in the shell, some shelled peanuts, and foreign objects (e.g., leaves, nodes, weed seed, etc.). The peanuts are then cleaned using cleaning machine so that oil is not contaminated with foreign materials. Therefore, it helps to preform the extraction process as efficiently as possible.