Wholesale Groundnut Oil Processing Machines in Tanzania

- Usage: machine for Peanut oil producing

- Type: machine for Peanut oil producing

- Production Capacity: 1-2000TPD

- Voltage: 220V/380V/440V

- Power(W): 7.5kw

- Dimension(L*W*H): 2000x1400x1850mm

- Weight: 1200kg

- Application: machine for Peanut oil producing

- Raw material: Peanut

- Material: Stainless Steel 304

- Function: machine for Peanut oil producing

- Character: machine for Peanut oil producing

- Warranty: 2 Years

- Feature: Feeding Automatically

- Quality: Top Level

- Wearing parts: Squeeze Spiral

Groundnut Oil Extraction Process, Peanut M. The extraction of oil can be divided into one pressing and prepressing. A press called full press, press process requirements will peanut oil press material as much as possible to squeeze the oil in cake 3% ~ 5%. The pre press press process requires only about 70% of the oil press material is pressed

After pressing, crude peanut oil still remain impurities in the extracted oil. To aid in the removal of the remaining impurities, oil filter press machines are usually employed. The filtration systems are able to remove large and small size particulates, and even water from the oil. Read more : Groundnut Oil Refinery Process

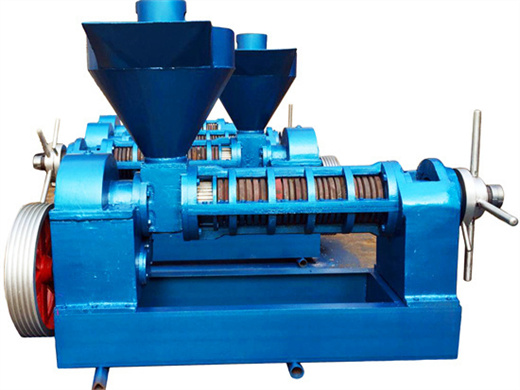

New Design Peanut Oil Press Machine Mini Peanut Oil Press Peanut Oil Press Machine With Low Price

- Usage: beans/Peanut etc

- Type: Peanut Oil Press Machine

- Production Capacity: 3-500 kg/h

- Voltage: 180V-240V/50-60HZ

- Power: 350w/400w

- Dimension(L*W*H): 47.5*25*41cm

- Weight: 12kg/14kg

- Used for: Peanut/ Peanut/ nuts/ Peanut/ vegetable seeds/flaxseeds

- Keep working: 24 hours

- Color: Stainless steel

- Feature: Cold/hot pressing

- Advantage: Easy use,energy saving

- Advantage: : Simple operation

- Packaging Detail: Bubble foam

- Carton size: : 47.5*25*41cm

3, And then preheat the oil press, after the oil press preheat, while hot pour the fried peanuts into the oil press feed hopper. Start the oil extraction switch and carry out oil extraction. Generally need to be squeezed two to three times, generally use the screw oil press, there are automatic machine processing, as long as the prior setting

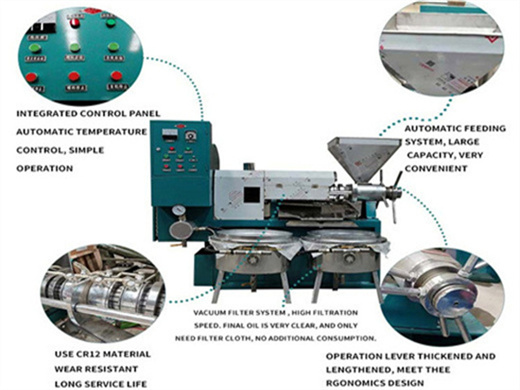

The pressure breaks down the cellular structure of the peanuts, allowing the peanut oil to be extracted. Next, the peanut oil moves through the vacuum filtering section, where any oil residue is separated and collected on top of the filter cloth. In the end, we obtain clean peanut oil. This outlines the complete process of extracting groundnut oil.

peanut oil processing and basic principle and method of

- Usage: rbd Peanut oil

- Type: rbd Peanut oil machinery, rbd Peanut oil machinery

- Production Capacity: 1TPD-100TPD

- Voltage: According to customer demand

- Power(W): According to project

- Dimension(L*W*H): According to project

- Weight: According to customer demand

- Color: Silver

- Production Material: Carbon steel, stainless steel

- Raw material: Peanut

- Export markets: Europe, Southeast Asia, Africa, etc

- Work principle: Mechanical principle

- Warranty period: One year

- English manual: Yes

- Factory visiting: Yes

Highly efficient centrifugal oil filtering equipment suitable for a great deal of crude oils, including rapeseed oil, cotton seed oil, peanut oil, peanut oil, flax seed oil, sunflower seed oil, corn germ oil, Peanut kernel oil, etc. 5. The type of centrifugal oil filter is perfect to match with various screw oil press machines.

The peanuts are then placed in a conditioning tank, where the pressing temperature and moisture are adjusted to maximize the oil yield. To commercially extract cold-pressed peanut oil, a twin-screw press is used, and the pressing is performed at specific temperatures that do not exceed 60 °C.

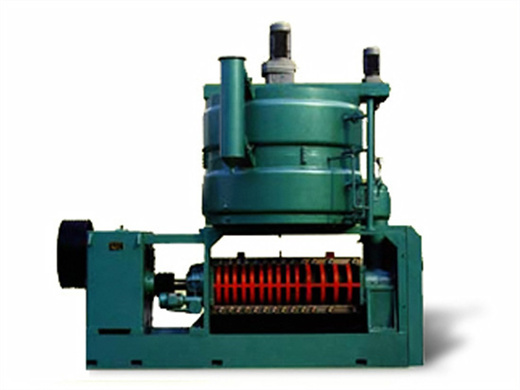

Peanut oil press production line Oil press machine

- Usage: Peanut Oil

- Production Capacity: 200~2000T/D(daily processing capacity)

- Voltage: 380

- Power(W): Standard

- Dimension(L*W*H): Standard

- Weight: Standard

- Product name: 200-300t/d Peanut oil pressing machines

- Expanding,Extraction,Refinery: Color: Silver

- Raw material: Peanut

- Advantage: Energy Saving

- Feature: Multifunction

The oil extraction quality is also related to the operating proficiency of the operators. People who are not skilled in equipment operation may over-roast peanuts. The peanut oil squeezed with over-roasted peanuts will have a bitter taste, and the color of the peanut oil is not bright. Select good oil press and oil filtering equipment.

Advanced nut processing with the peanut oil press machine

- Usage: Peanut Oil

- Type: Cold & Hot Pressing Machine, food grade oil filter/Peanut mill

- Production Capacity: 10-5000T/D

- Voltage: 220V/380V/415V

- Power: 2.2KW

- Dimension(L*W*H): 1910*550*765 mm

- Weight: 420 KG

- Raw material: Peanut

- Function: Peanut oil

- Suitable for: Peanut,etc

A peanut oil press machine is your gateway to a more efficient and cost-effective peanut oil production process. It’s a business production powerhouse that does more than just squeeze oil out of peanuts. It streamlines the entire process and results in a high-quality, accurate product The automatic peanut oil Press is a popular model.

- How is peanut oil extracted?

- Mechanical pressing can extract 85% oil and the remaining oil is extracted by the solvent extraction method. According to mechanical pressing technology, you can divide the peanut oil production process into three phases. These are peanuts preparation, pressing and crude oil refining. Step 1: Cleaning Step 2: Dehulling Step 3: Cooking

- How to make peanut oil from groundnuts?

- According to mechanical pressing technology, you can divide the peanut oil production process into three phases. These are peanuts preparation, pressing and crude oil refining. Step 1: Cleaning Step 2: Dehulling Step 3: Cooking Step 4: Pressing Step 5: Filtration After harvesting groundnut are received at processing facilities.

- What is peanut oil production process?

- The peanut oil production process involves peanut preparation, pressing and crude oil refining.

- Why do we use a cleaning machine for peanut extraction?

- Batches of harvested peanuts will contain whole peanuts in the shell, some shelled peanuts, and foreign objects (e.g., leaves, nodes, weed seed, etc.). The peanuts are then cleaned using cleaning machine so that oil is not contaminated with foreign materials. Therefore, it helps to preform the extraction process as efficiently as possible.

- What is groundnut oil manufacturing process?

- Groundnut oil manufacturing process is divided into two methods, the first is mechanical pressing and the second is solvent extraction. Mechanical pressing can extract 85% oil and the remaining oil is extracted by the solvent extraction method.

- Why do we dehull peanut oil before oil pressing?

- The purpose of dehulling before oil pressing is to reduce the absorption of oil by the shell, increase the yield of oil, improve the processing efficiency of the peanut oil processing machine and reduce equipment wear and tear. This oil can also improve cake quality and added value.