Groundnut Oil Manufacturing Machine

- Usage: Peanut oil project egypt

- Production Capacity: 100%

- Voltage: 380V/50HZ

- Power(W): 15KW

- Dimension(L*W*H): 1700*1100*1600mm

- Weight: 1200kg

- Raw material: Peanut

- Color: processing Peanuts

- Material: Peanut

- Application: Peanut oil press

- Advantage: high quality best price

- Warranty: 12 month

- Feature: Peanut oil project egypt

- Character: engineer service

- Use: Peanut oil pressing

After pressing, crude peanut oil still remain impurities in the extracted oil. To aid in the removal of the remaining impurities, oil filter press machines are usually employed. The filtration systems are able to remove large and small size particulates, and even water from the oil. Read more : Groundnut Oil Refinery Process

A step by step guide for Groundnut oil making process, business plan: Today, let us discuss the groundnut oil production process, extraction methods, and business plant including groundnut oil plant (machine) cost in India. Groundnut oil is also known as peanut oil or Arachis oil, is a mild-tasting vegetable oil expressed from groundnut kernels

2024 Wholesale Price Supply Oil Press Small Manual Oil Press For Sale

- Usage: home small oil presser

- Type: Peanut Oil Press Machine

- Production Capacity: 5TPD-100TPD, 98%-100%

- Voltage: 220V/50HZ, 220V/50HZ

- Dimension(L*W*H): 450*180*310mm

- Weight: 11kg, 11kg

- Core Components: Motor

- Oil type: Peanut Oil

- Function: Making Edible Oil

- Advantage: Energy Saving

- Material: Stainless Steel

- Capacity: 40-600kg/H

- Oil yield: 2-3kg/H

- Raw material: Peanut,ect

- After-sales Service Provided: Video technical support, Online support

Organic groundnut oil or peanut oil has a lot of health benefits. In this video, we explore the production process of organic groundnut oil in northern Ghana

Peanut Oil Production Line. Peanut is a kind of oilseed with high oil content. The oil can be obtained from peanuts by pressing process. Groundnut oil contains more than 80% unsaturated fatty acids (including 41.2% oleic acid and 37.6% linoleic acid). Besides, there are also Peanutitic acid, stearic acid, and other saturated fatty acids which

AS145 groundnut oil cooking oil process line home use

- Usage: Peanut Oil Processing

- Type: Peanut Oil Press Machine

- Production Capacity: 50-1000kg/h

- Voltage: 220V/380V/440V

- Dimension(L*W*H): 1700*1100*900cm

- Weight: 1200 KG

- Warranty: 1 Year, 12 Months Peanut oil machine prices in sri lanka

- Core Components: Motor, Pressure vessel, Pump, Gear, Bearing, Engine, Gearbox

- Oil type: Peanut Oil

- Raw material: Peanut ,etc

- Application: Oil Production Line

- Advantage: Energy Saving

- Function: Making Edible Oil

- Product name: Peanut oil machine prices in sri lanka

- Material: Stainess Steel

- Color: Clients' Requirements Peanut oil machine prices in sri lanka

- Capacity: Large Peanut oil machine prices in sri lanka

Leader Edible Oil Refining Processes developed a new kind of AS145 groundnut oil cooking oil process line home use set (capacity 1~30 ton per day).Peanut Oil Processing Machines, Wholesale Various High Quality Peanut Oil Processing Machine Products from Global Peanut Oil Processing Machine Suppliers and Peanut Oil Processing Machine Factory,Importer,Exporter at Leader Edible Oil Refining Processes

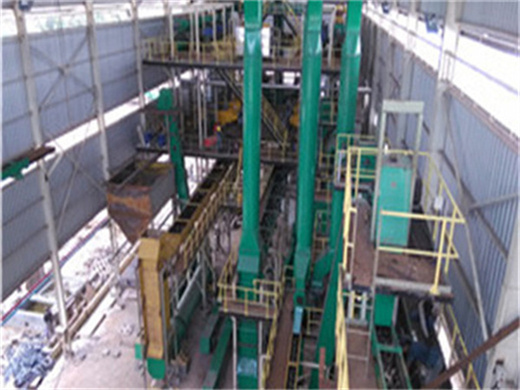

Large oil mill usually use a pre-squeezing leaching process to produce groundnut oil. Pre-squeezing leaching process is first squeezing the most of oil, and the groundnut cakes are performed for solvent extraction, further extract the oil left in the oil cake, and increase the oil output rate of the oil.

AS145 groundnut oil cooking oil process line home use

- Usage: Peanut Oil

- Type: Peanut oil extraction machine

- Production Capacity: 100%

- Voltage: 380V

- Power(W): according to capacity

- Dimension(L*W*H): various with capacity

- Weight: changed with capacity

- Raw material: Peanut

- Product: Automatic Crude Peanut oil decolorization line

- Capacity: 1-3000TPD Peanut oil extraction machine

- Oil content: from 18-22%

- Oil residues: less than 1%

- Function: Peanut oil extraction machine

- Manufacturing experience: 40 years

- Material of equipment: stainless steel and carbon steel

Expeller Pressed Machine developed a new kind of AS145 groundnut oil cooking oil process line home use set (capacity 1~130 ton per day).It can process various kinds of Oil Fractionation Equipment, including all kinds of vegetable oil, seeds oil and Peanut oil.manufacture of Oil fractionation equipment,Oil is a compound of many kinds of glycerol triester.

Affordable Peanut Oil Production Line Groundnut Oil Processing Machine

- Usage: Solvent extraction oil from various raw material seeds

- Type: Oil solvent extraction

- Production Capacity: 100%

- Voltage: 220V/380V/440V

- Power(W): According to the capacity

- Dimension(L*W*H): 1610x615x1260mm

- Weight: 1050 KG

- Item: Have A Long Standing Reputation Peanut Oil Extracting Mill

- Feature: High output

- Performance: Perfect

- Application: Oil Production Line

- Manufacturing experience: Edible Oil Field

- Advantage: Professional engineer team in oil extraction plant design

- Capacity: 10--3000TPD

- Type of extractor: Rotocel extractor, Loop type extractor,Chain Extractor,

The groundnut oil squeezed by an automated peanut oil processing machine is clean, free of impurities, and of good quality. The peanut oil pressing line mainly includes a peanut shelling machine, roasting machine, oil press, vacuum oil filter, and oil filling machine. The peanut oil pressing process mainly includes hot pressing and cold pressing.

- How to make peanut oil from groundnuts?

- According to mechanical pressing technology, you can divide the peanut oil production process into three phases. These are peanuts preparation, pressing and crude oil refining. Step 1: Cleaning Step 2: Dehulling Step 3: Cooking Step 4: Pressing Step 5: Filtration After harvesting groundnut are received at processing facilities.

- What is peanut oil production process?

- The peanut oil production process involves peanut preparation, pressing and crude oil refining.

- What is groundnut oil manufacturing process?

- Groundnut oil manufacturing process is divided into two methods, the first is mechanical pressing and the second is solvent extraction. Mechanical pressing can extract 85% oil and the remaining oil is extracted by the solvent extraction method.

- How is peanut oil extracted?

- Mechanical pressing can extract 85% oil and the remaining oil is extracted by the solvent extraction method. According to mechanical pressing technology, you can divide the peanut oil production process into three phases. These are peanuts preparation, pressing and crude oil refining. Step 1: Cleaning Step 2: Dehulling Step 3: Cooking

- Why do we dehull peanut oil before oil pressing?

- The purpose of dehulling before oil pressing is to reduce the absorption of oil by the shell, increase the yield of oil, improve the processing efficiency of the peanut oil processing machine and reduce equipment wear and tear. This oil can also improve cake quality and added value.

- Why do we use a cleaning machine for peanut extraction?

- Batches of harvested peanuts will contain whole peanuts in the shell, some shelled peanuts, and foreign objects (e.g., leaves, nodes, weed seed, etc.). The peanuts are then cleaned using cleaning machine so that oil is not contaminated with foreign materials. Therefore, it helps to preform the extraction process as efficiently as possible.