Small Scale Sunflower Seed Oil Press Machine

- Size: 67*24*42cm

- Pressed: Sunflowers

- Raw material: Sunflower

- Advantage: Easy Operation, Energy Saving

- Oil Stage: Food Stage

- Packing: International Packing Standard, Wooden Packing

- Usage: Making Edible Oil

- Operate: Cold & Hot Pressing Machine

- Type: Spiral Oil Press

- Application: All, Beans, Sunflower

- Appearance: Horizontal

- Customized: Customized

- Press Materials: Fruit Sunflower Oil, Sunflower etc.

- Transport Package: Poly Wood Package for Sea Freight

- Specification: 67*24*42cm

- Production Capacity: 10000

Typically, the conventional screw small scale oil press machine is composed of a feeder, a gearbox, pressing cage, a screw shaft, and the extraction stand. All these are combined to realize continuous sunflower seed oil extraction with easier operations.

The above steps outline the process of making sunflower oil. Some steps can be customized based on specific requirements. This process also applies to other vegetable seeds and nuts, such as cottonseeds, peanuts, and palm kernels. The equipment and machinery needed for a sunflower oil processing plant vary based on the scale of production.

COOKING OIL PROCESSING MACHINE LIST cooking oil making machine

- Usage: Other

- Type: Sunflower Oil Press Machine

- Production Capacity: 1-50 Kg / H

- Voltage: 220 - 240 Volt

- Dimension(L*W*H): 840*240*540 mm

- Weight: 65 KG

- Warranty: 2 years

- Warranty of core components: 2 years

- Core Components: Motor, Bearing, Gearbox, motor driver

- Oil type: Sunflower Oil

- Thermostat: Temperature Control 600 Watt

- Gear Box: Helical Shaft Gear

- Energy Consumption: 400- 1500 Watt/Hour

- Motor Power: 1.5 kW

- Raw material: STEEL

| COOKING OIL PROCESSING MACHINE LIST OIL PRESS MACHINE Type 1: Hydraulic oil Press Machine Capacity:25-30kg/h, 40-50kg/h,50-60kg/h, 70-80kg/h Suitable for: peanuts, flax seed, sesame, rapeseed, sunflower Suitable for:seed, cottonseed, soybean and more than 30 kinds Suitable for:of oil seeds

Ideal for large-scale oil processing plants, this innovative machine combines advanced pressing technology with low-temperature processing to maximize oil yield and produce superior-quality oil. The embryo temperature is about 70℃, it is not only to ensure the low denaturation of protein in the cake but also to ensure a high oil yield.

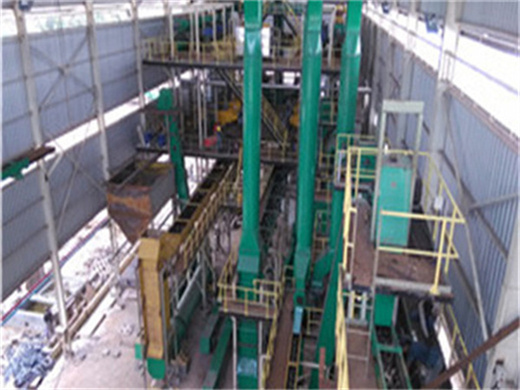

Sunflower Oil Processing Oil Mill Plant

- Type: Hot Press

- Application: press wood waste into wood pallet/wood tray for transportation

- Pressure: 1000T

- Voltage: 380V,50Hz,3phases

- Power(W): 18500W

- Weight: 25T

- Color: green,also can be designed

- Structure: four-column-oriented

- Pallet mold: can be designed

- wood pallet making machine pallet size: 1200*1000*10-20mm

- Pallet stastic load: 12T

- Pallet dynamic load: 3-5T

- Glue: needed,had better UF glue

- Materials needed: thermal oil, hydraulic oil

- wood pallet making machine line: can be equipped

- Max working pressure: 25MPA

? Grading the seeds into large, medium and small sizes Seeds to be marketed as in-shell are bagged Seeds to be sold as kernel are hulled and then bagged Storage. Sunflower Oil Processing Plants. There types of sunflower oil available are mid-oleic linoleic and high oleic sunflower oil. All are developed with standard breeding

Small Scale Sunflower Oil Processing Line. Sunflower oil processing involves many process that will decide the equipment and machinery for a sunflower oil processing plant. For small scale sunflower oil processing line, the equipment may be relatively simple and easy to operate. Of course, the investment cost for small scale oil factory is low

PJSC ?Zaporozhien OEP

- Usage: Sunflower Oil

- Type: For home Sunflower oil press machine usage

- Production Capacity: 10-5000 ton

- Voltage: 380V 440V

- Power(W): As home Sunflower oil press machine output every day

- Dimension(L*W*H): Depend on home Sunflower oil press machine capacity

- Weight: As home Sunflower oil press machine output

- Item: home Sunflower oil press machine

- Material: Stainless steel

- Rate of Sunflower oil extraction: 40-53%

- Grades of Sunflower oil: one grade ,two grade ,three grade ,

- Method of extracting Sunflower: Pre-press then leaching

- Oil in the cake after press: 12-13%

- Oil in the cake after extraction: 1%

- Solvent residual after desolventizer: <300ppm

- Distillation range: 68-75℃

- Payment: l/c t/t

Since the 60’s a period of large-scale development of the plant, increasing of its production capacity and equipment started. 1961 installation for cooling and shaping of soap 1962-1964гг reconstruction of the oil extraction plant. 1966-1967гг installation for continuous deodorization of “DeSmet” hydrogenated fat.

Setup Cooking Oil Production Line Business in Zambia

- Usage: Press oil

- Type: Sunflower oil Processing Equipment

- Production Capacity: 60%

- Voltage: 380V

- Dimension(L*W*H): 2200*1400*1700mm

- Weight: 1420 KG

- Core Components: Motor

- Oil type: Sunflower Oil

- Product name: MX-150 hot and cold pressing automatic cooking oil press machine

- Feature: Automatic Machine

- Color: Customizable Color

- Use for: Seed Oil Press

- Package: Wooden Case

- Quality: Top Level

- Raw material: Sunflower

- Capacity: 70~500kg/h

Small Oil Mill Plant for Cooking Oil Business. However, large scale cooking oil processing plant will be designed completely with all necessary cooking oil manufacturing machines. Large Oil Mill Plant for Cooking Oil Business. Small Scale Cooking Oil Press Machines for Sales. Cooking Oil Making Machines at Factory Price

- What is a sunflower oil extraction plant?

- This sunflower oil extraction plant contains sunflower seeds pretreatment machines and sunflower oil pressing machines, which can efficiently extract sunflower oil from sunflower seeds.

- Which countries produce sunflower seeds for oil?

- Our oil mill machinery and equipment deserve praise for their excellent quality. The countries producing sunflower seeds for oil include Ukraine, Russia, Argentina, China, Romania, Bulgaria, Turkey, Hungary, USA, and Tanzania. We undertake turnkey project solutions for the complete sunflower seed oil extraction plant.

- How to start a sunflower oil mill plant?

- To start a sunflower oil mill plant, there are several basic machinery requirements that need to be met. These include machinery for seed cleaning, seed conditioning, oil extraction, oil filtration, steam generation, and oil filling. There are various processes involved in Sunflower Oil Mill Plants.

- What are the processes involved in sunflower oil mill plants?

- In a Sunflower Oil Mill Plant, several processes are involved: Seed Cleaning, Seed Conditioning, Oil Extraction, Oil Filtration, Steam Generation, and Oil Filling. Before oil extraction, oilseed is passed through the seeds cleaner to remove impurities such as dust, leaves, and metals.

- How are sunflower seeds conditioned?

- Before oil extraction, sunflower seeds are conditioned using steam in a Vertical Cooking Kettle. This process is essential to prepare the seeds for optimal oil extraction. The conditioned sunflower seeds are then fed into the chamber for oil extraction. The sunflower seeds contain 35 – 40 % oil content and double pressing is required to extract maximum oil, leaving 9 – 11 % residual oil in the sunflower meal which is an excellent source of Animal Feed.

- How is sunflower oil filtered?

- After extraction, crude sunflower oil is filtered to remove the 'foots'. The filtration process removes impurities, resulting in clear Filtered Sunflower Oil. We have been engaged in manufacturing and exporting a wide array of Plate type, Plate and Frame Filter Presses.