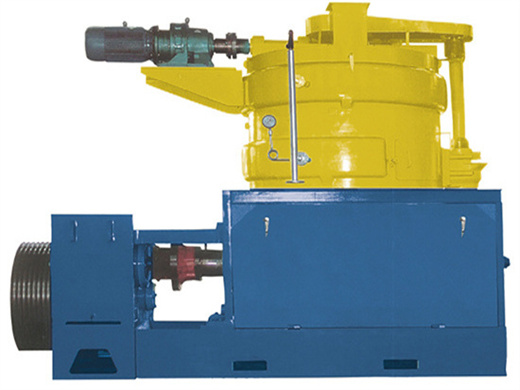

Sunflower oil processing plant cooking oil making machine

- Usage: Sunflower Oil, Sunflower EDIBLE OIL

- Production Capacity: 30~60 ton/day

- Voltage: Depend

- Dimension(L*W*H): Depend

- Weight: KG

- Core Components: Gearbox

- Oil type: Sunflower Oil

- complete Warranty Service: Video technical support

- On Site Warranty Service: Field maintenance and repair service

- Raw material: Sunflower

- Product name: Oli Press Machine

- Function: Making Edible Oil

- Application: Edible Oil Production

It is usually suitable for large capacity sunflower oil processing plant above 20tpd. The processing flow chart of sunflower oil solvent extraction plant. 3. Sunflower oil refining section: Sunflower oil refinery plant is to remove harmful impuries and useless substance, such as protein, phospholipid, pigment, moisture, wax and other impurities.

Market Trends in Sunflower Oil: Since sunflower seeds being grown using traditional breeding techniques and not containing genetically modified (GM) components, the consumption of sunflower oil will be continuously increase as consumers worldwide are increasingly seeking non-GMO and low-saturated fat food options that comply with dietary restrictions.

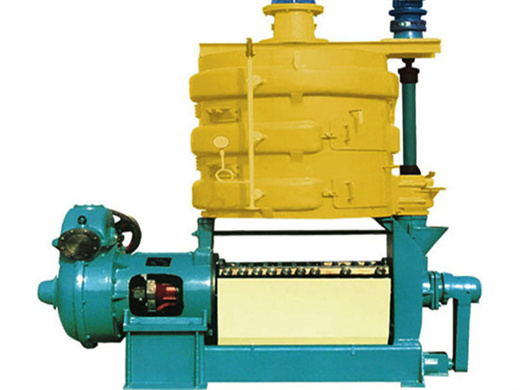

Complete Sunflower Oil Processing Plant Sunflower Oil Press Extract Machine

- Usage: black cumin seed oil press machine

- Production Capacity: 10tpd-100%

- Voltage: 220V/380V/440V

- Power: 3kw

- Dimension(L*W*H): 1400x860x1260mm

- Weight: 280kg

- Raw material: steel

- Application range: Sunflower

- Function: Oil Press + One Drum Filter

- Advantage: Energy Saving

- Feature: Flexiable

- Model: 6YL-70

- Quality: Top Level

- Capacity: 50-80kg/h

3 percent annually. About half of the oil consumed is imported, i.e., nearly 170,000 tons in 2009. Investment in sunflower oil production locally could therefore provide competition against imported oil. One reason for encouraging the greater production and processing of sunflower oil in Tanzania is thus its potential for import substitution,

agribusiness handbook Food and Agriculture Organization. 2.5 World production of sunflower oil and main producing countries21 2.6 Sunflower oil prices 24 2.7 Sunflower oil domestic use 25 2.8 International trade in sunflower oil 26 3.

Screw Type Sunflower Oil Milling Machine Sunflower Oil Press Machine

- Usage: Cooking Oil

- Type: Sunflower Oil Press Machine

- Voltage: 220v,50hz

- Dimension(L*W*H): 43*20*55 cm

- Weight: 250KG

- Raw material: Sunflower,Avocado

- Function: Press Oil Seeds

- Material: 304 Stainless Steel

- Color: Silver

- Feature: High Oil Yield Efficiency

- Application range: Kinds Seeds

- Item: Edible Oil Press

- Extraction of Oilseeds: 90% Oil Yield

Small Scale Sunflower Oil Processing Line. Sunflower oil processing involves many process that will decide the equipment and machinery for a sunflower oil processing plant. For small scale sunflower oil processing line, the equipment may be relatively simple and easy to operate. Of course, the investment cost for small scale oil factory is low

Filtering and Processing Sunflower Oil. Once the sunflower oil is extracted from the seeds, it needs to be filtered and processed to remove any impurities. This is done to ensure the oil is high-quality and nutritious. The process of filtering and processing sunflower oil is relatively straightforward.

Cooking Oil Processing from Various Raw Materials

- Usage: turkey Sunflower oil extraction machine

- Production Capacity: 20tpd-100%

- Voltage: 220V/380V/440V

- Power: 2.2KW

- Dimension(L*W*H): 1200x780x1100mm

- Weight: 220kg

- Product name: turkey Sunflower oil extraction machine

- screw diameter: 55mm

- rotary speed: 52r/min

- motor power: 2.2kw

- heater power: 0.9kw

- capacity: 50kg/h

- weight: 220kw

- Application: all kinds of vegetable seeds and nuts

- Advantage: Energy Saving

Customers sometimes express the desire to produce multiple types of cooking oil using a single machine. In response, it should be noted that high oil-content raw materials typically undergo pretreatment, pre-pressing, and solvent extraction methods, whereas low oil-content raw materials are directly used in the refining method after the pretreatment.

Sunflower seed oil production manufacturing process analysis

- Usage: Sunflower oil production plant

- Production Capacity: 20TPD-1000TPD

- Voltage: 380V,440V

- Dimension(L*W*H): 48m*12M*15M(30TPD)

- Weight: 6000 KG

- Core Components: Motor, Engine

- Oil type: Sunflower Oil

- Product name: Oil Refining Production Line

- Raw material: Sunflower Oil

- Advantage 1: High oil output

- Material: carbon steel or stainless steel

- oil meal residue: <6%

- production capacity: 20TPD-1000TPD

- Application: Oil Production Line

- Advantage 2: for refining various crude oil

- Advantage 3: automatic with big capacity

Sunflower oil production contains the following manufacturing processes:1.Sunflower seeds cleaning,dehulling,flaking,cooking,pressing;2.Using solvent to extract crude sunflower oil from sunflower seeds;3.Refining the crude sunflower oil into refined oil.

- What is a sunflower oil manufacturing machine?

- A sunflower oil manufacturing machine is designed to process sunflower seeds into oil through a series of steps that involve cleaning, pressing, and refining. These machines are used in small-scale operations, medium-sized businesses, and large industrial facilities to produce edible sunflower oil efficiently. 1. Seed Cleaning Machines:

- What are the different types of sunflower oil extraction machines?

- Sunflower Oil Expeller/Pressing Machine: - Cold Pressing: Seeds are pressed at a low temperature to retain nutrients and produce high-quality oil. - Hot Pressing: Seeds are preheated before pressing to extract more oil. Common in larger-scale production to maximize yield. 4. Oil Filtration Machine:

- What is oil refining machine?

- Oil Refining Machine (Optional): - Used for refining crude sunflower oil to remove unwanted components such as free fatty acids, phospholipids, and pigments. - Results in clearer, higher-quality oil that has a longer shelf life and better taste. - Typically includes neutralization, degumming, decolorization, and deodorization stages.

- Who is CV Sumber aromatik Indonesia?

- CV Sumber Aromatik Indonesia wasfounded in 2011with the aim to developessentialoil industry business,over journey time dueto thereputation and performance aswell as agood network, CV SumberAromatik ...