Sunflower Oil Extraction Process, Methods A Full Guide

- Usage: oil press machine

- Production Capacity: 5TPD-100TPD

- Voltage: 110V,220V

- Dimension(L*W*H): 75*83*122 cm

- Weight: 125 KG

- Warranty: 3 years

- Warranty of core components: 2 years

- Core Components: Motor, Bearing, Engine

- Oil type: Sunflower Oil

- Product name: oil press machine

- capacity: 30kg/h raw materials

- output: 150kg/h oil

- control mode: cold&hot pressing

- Material: stainless steel

- Packing size: 99*86*102 cm

- Packing quantity: 1 piece in a carton

- Gross weight: 150 kg

- Work time: keep working 24 hours

- Raw materials: Sunflower etc..

The solvent extraction procedure uses hexane or other solvents to wash the sunflower oil from the prepared flakes. The design of the equipment varies so that Crown can optimize the amount of solvent and bed depth required to efficiently wash the flakes, the contact time of the solvent and flakes and the power and utilities desirable to run the

A sunflower solvent extraction plant is designed to extract oil from sunflower seeds using solvent-based extraction methods,SHFT Exported sunflower oil processing machines,Sunflower seed oil extraction process, Sunflower seed oil production plant to many countries of african continent.

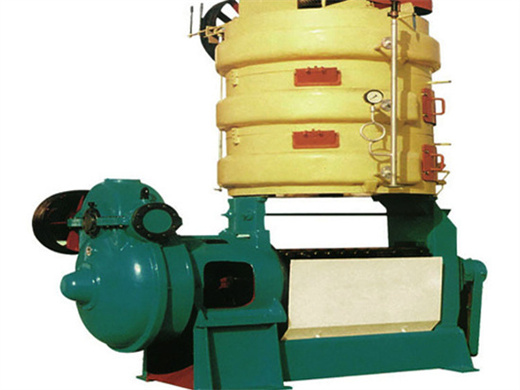

Different extraction methods of sunflower oil: pressing

- Usage: Sunflower Oil, Cooking Oil

- Voltage: 380v

- Dimension(L*W*H): 3100*1500*2800mm

- Weight: 6000 KG

- Core Components: Gearbox

- Oil type: Sunflower Oil

- Product name: HNX220

- Application: oil production line

- Capacity: 10-12T/D

- Oil rate: 5~8%

- Machinery type: Automatic Screw Oil Press

- Power: 18.5kw

- Use for: oil press

- Press type: screw cold hot oil press

- Application range: edible oil press

The sunflower oil solvent extraction method is a chemical method that uses a chemical solvent to extract oil from the raw material. Compared with the sunflower oil pressing method, the sunflower oil solvent extraction method has a higher oil yield but also higher cost. In addition, the sunflower oil solvent extraction method requires the use of

Hexane is passed through the expeller oil cake or meal to obtain a mixture of oil and solvent called miscella. Solvent is removed from the oil and the remaining meal in separate equipments to obtain desolventized sunflower oil and meal. Large capacity solvent extraction plants are used to produce solvent-extracted sunflower oil on commercial scale.

methods and equipment for sunflower oil solvent

- Usage: Sunflower Oil Making Machine Price

- Type: Cold & Hot Pressing Machine, Sunflower Oil Making Machine

- Production Capacity: 35-550kg/h

- Voltage: 380V,220V

- Power: 2.2KW

- Dimension(L*W*H): 900*850*1550 mm

- Weight: 420 KG

- After-sales Service Provided: Overseas service center available

- Size: 900*850*1550 mm

- Processing capacity: 35-550kg/h

- Raw material: Sunflower

- Material: Stainless Steel 304

- Color: Custom-made

- Advantage: Energy Saving

- Function: Press Oil Seeds

However, the use of the sunflower oil solvent extraction method for processing sunflower oil is usually suitable for sunflower oil producers with a raw material processing capacity of more than 20 tons per day. If the processing capacity is relatively small, it is recommended to use the sunflower oil pressing method for processing sunflower oil.

1. What is the best extraction method for sunflower oil? Mechanical pressing and solvent extraction are the most common methods used for sunflower oil extraction. Both methods have their advantages and disadvantages. The choice depends on several factors, such as the quality of the seeds, the yield required, and the desired quality of the oil. 2.

List of Solvent Plants in Pakistan 4 PDF Papua New Guinea congo

- Usage: soyabean oil machine

- Production Capacity: 80kg/h, 500kg/h, 100kg/h

- Voltage: 220V/380V/440V

- Power(W): 22kw

- Dimension(L*W*H): 48m*12M*15M(30TPD)

- Weight: 30tons

- Item: Sunflower

- Raw material: Sunflower

- Machine Color: Silver/Green/Yellow

- Application: Oil Production Line

- Production period: 45-90 days

- Installation period: 60-90 days

- Supplier Type: manufacturer

- Character: Continuous

- Advantage: Zero Pollution

This document lists 26 solvent extraction plants in Pakistan with their contact information including name, contact person, address, phone numbers and email addresses. The plants are grouped by location including Bahawalpur, Faisalabad, Hyderabad, Jhang, Jamshoro and Papua New Guinea. For each plant, key contact details are provided for easy communication.

Sunflower Oil Mill Machinery In Kerala Sunflower Seed Oil Press Complete Set For Oil Pressing

- Usage: extraction

- Production Capacity: 60%

- Voltage: 220V

- Dimension(L*W*H): 64*29*71CM

- Weight: 70 KG

- Core Components: Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Engine, Gearbox

- Oil type: Sunflower Oil

- Product name: automatic oil press machine Sunflower Oil Sunflower oil Sunflower oil

- Function: Press Oil Seeds

- Application: Food Industry

- Machine Material: Customized SUS304

- Feature: High Oil Yield Efficiency

- Advantage: Long Service Life

- Raw materials suitable: Food Crude Oil

- MOQ: 1 Set

- After-sales Service Provided: Online Video Technical Support

The quality of the oil depends on the quality of the seeds and the method of extraction used. Cold-pressed sunflower oil is generally regarded as the highest quality, as it retains all of its beneficial compounds. On the other hand, solvent-extracted sunflower oil is usually lower in quality, as the solvents can affect the oils beneficial

- How is sunflower crushed for oil recovery?

- Sunflower is crushed for oil recovery via one of two process methods, hard pressing or prepress solvent extraction. Hard pressing relies upon exerting high pressure on the prepared seed to separate oil from the solids fraction, historically recovering about 25% oil from the seed.

- Why is prepress solvent extraction better than sunflower meal?

- Because sunflower oil has a substantially higher economic value than sunflower meal, process economics improve significantly as the oil recovery yield increases. Therefore, prepress solvent extraction, with the highest oil recovery yield, is the process method utilized today for the majority of the sunflower seed that is crushed globally.

- What are the different methods of sunflower oil extraction?

- Mechanical pressing and solvent extraction are the most common methods used for sunflower oil extraction. Both methods have their advantages and disadvantages. The choice depends on several factors, such as the quality of the seeds, the yield required, and the desired quality of the oil.

- How to extract sunflower oil?

- The process of extracting sunflower oil involves various steps, such as: The extraction method used depends on the desired quality and yield of the oil: Mechanical pressing is a popular method that involves squeezing the seeds using a machine to extract the oil.

- What is a prepress solvent extraction method in a sunflower crushing plant?

- In a typical sunflower crushing plant using the prepress solvent extraction method, the initial steps of seed pre-cleaning and seed drying are located in the seed receiving section of the facility, prior to seed storage.

- How does a sunflower extractor recover the solvent pumped to the extractor?

- The solvent evaporated from the sunflower meal and the miscella are both recovered in the solvent recovery system within the solvent extraction process area. A typical sunflower plant will recover 99.8–99.9% of the solvent pumped to the extractor.