How Much Does a Sunflower Oil Refinery Plant Cost

- Usage: Sunflower Oil

- Production Capacity: 100-500kg/h

- Weight: 0 KG

- Warranty: One Year warranty against manufacturer defect.

- Warranty of core components: Other

- Core Components: Other

- Oil type: Sunflower Oil

- Raw material: Oil Seeds

- complete Warranty Service: Video technical support

- On Site Warranty Service: Field maintenance and repair service

- Function: Making Edible Oil

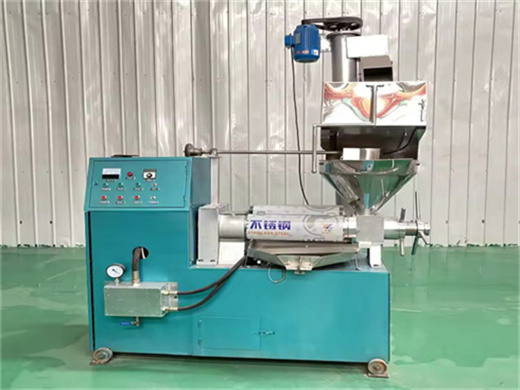

- Product name: Oli Press Machine

- Application: Edible Oil Production

- Keyword 1: Oil Making Press Machine

The cost of setting up a sunflower oil refining plant involves a number of aspects, including raw material costs, processing equipment, human resources, infrastructure, transportation and storage. The first step in starting a sunflower oil refinery plant is investment in oil refinery machines. These sunflower oil making machines not only

Start Your Own Profitable Sunflower Oil Milling Factory Business. Sunflower seed oil is the raw material for sunflower oil pressing/extraction, with an oil content of about 30-48%, which is a high oil content oil-bearing crop. Whenever you want to start a sunflower oil factory, the project cost must be your biggest concern.

Invest in Affordable Small Sunflower Oil Production Line

- Usage: Sunflower Oil

- Production Capacity: 90T~130T/D

- Voltage: 220V/380V

- Power(W): According to capacity

- Dimension(L*W*H): 1200*400*900mm3

- Crude protein: 43%

- Waste bleaching earth oil content: <35%

- Deodorization loss consumption: ≤0.5%

- Steam consumption: 450kg/T oil

- Bleaching earth consumption: 5~50Kg/T oil

- Business type: manufacturer

- Raw material: Sunflower

- Materials: Carbon steel Q235 and stainless steel

- Brand: Qi'e

The cost of setting up a sunflower seed oil factory is closely related with many factors such as oil mill capacity, process design, equipment selection, factory layout, automation degree of the production line. Here we can give your some references on equipment cost of sunflower cooking oil production line: The cost of 5ton/day oil pressing

1~30TPD Small Scale Sunflower Oil Refining Machine at Factory Price. Small scale sunflower oil refinery machine is designed for small and medium scale Sunflower Oil Processing Plant. It is the batch type oil refining equipment, but has all the functions of continuous oil refinery plant. (Related Machine: Mini Oil Refinery Plant Cost >>) 1TPD

cost to establish a sunflower oil refinery plant

- Usage: Sunflower Oil, Cooking Oil

- Production Capacity: High

- Voltage: 380V/50HZ

- Dimension(L*W*H): 2900*1850*3640 mm

- Weight: 5500 KG

- Warranty: 1 Year, Long Term Technical Support

- Core Components: Pressure vessel

- Oil type: Sunflower Oil

- Advantage: Final are more flavor and pure

- Raw material: Sunflower

- Function: Making Edible Oil

- Application: Edible Oil Production Line

- Product name: Screw Press Oil Expelle

- Material: Stainess Steel/Carbon Steel

If you don't want to cost too much or don't have large quantities of crude sunflower oil, you can consider the batch type sunflower oil refinery plant. It is low cost, small footprint and easy to operate. But it's worth noting that the raw material used to manufacture the refining tanks will influence the quality of sunflower oil refinery machine.

Fourth, pre-pressing sunflower seeds, here only pre-press part of sunflower oil, oil residue inside cake (about 12-16%) will be extracted in oil solvent extraction process. After pre-pressed, the crude sunflower oil will be delivered directly to sunflower oil refining workshop, and pressed cake to oil solvent extraction workshop.

What costs need to be considered to produce profitable

- Usage: Sunflower Oil

- Production Capacity: 150-200kg/h

- Voltage: 220V/380V

- Dimension(L*W*H): 1690*840*1370mm3

- Weight: 720 KG

- Warranty: 1 Year, 12 Months

- Core Components: machine

- Oil type: Sunflower Oil

- Color: Blue,customise

- Material: Carbon

- Raw material: Sunflower,Cottton seed,Teaseed

- Advantage: Automatic temperature control

- pressing power: 11kw-6p

- Main shaft heating power: 1.8kw-220v

- pressing cage heating power: 0.8kw-220v

Effective sunflower seed purchasing management can greatly affect profits. In addition to the raw material purchasing cost, the cost of sunflower seed processing, such as seed treatment to prevent diseases and pests, is also included. Sunflower seeds and sunflower oil. 2. Sunflower oil production machine investment cost. Modern sunflower oil

Sunflower Oil Manufacturing Plant Report 2025 Setup Cost

- Usage: Sunflower oil screw press

- Type: Sunflower oil screw press

- Production Capacity: 100%Sunflower oil screw press

- Voltage: 220V/380V/440V

- Power(W): 10-50kw

- Dimension(L*W*H): 1200*400*900mm3

- Weight: According to processing capacity

- Item: Sunflower oil screw press

- Raw material: Sunflower

- Steam pressure: ≥1.2MPa

- Voltatile substance in crude oil: ≤0.3%

- Steam consumption in refining: ≤280kg/ton of oil

- Oil residue in waste clay: ≤25% of waste clay

- Solvent contain in crude oil: ≤200ppm

- Oil residue in meal: <1%

- Warranty: 2years

- Feature: High Oil Yield Efficiency

IMARC Group’s report titled “Sunflower Oil Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue” provides a complete roadmap for setting up a sunflower oil manufacturing plant. It covers a comprehensive market overview to micro-level information such as

- What is the equipment cost of sunflower cooking oil production line?

- Here we can give your some references on equipment cost of sunflower cooking oil production line: The cost of 5ton/day oil pressing line is about $5500. The cost of 1ton/day oil refinery plant is about $19800. For 1ton/day sunflower oil dewaxing machine, the price is about $13000.

- What is a sunflower oil manufacturing machine?

- A sunflower oil manufacturing machine is designed to process sunflower seeds into oil through a series of steps that involve cleaning, pressing, and refining. These machines are used in small-scale operations, medium-sized businesses, and large industrial facilities to produce edible sunflower oil efficiently. 1. Seed Cleaning Machines:

- What is the process of sunflower seed dehulling machine?

- For industrial scale edible oil mill plant with daily capacity more than 20 tons, sunflower seed dehulling machine is necessary. The main process of fully scale sunflower oil processing plant is shelling, pre-pressing, solvent extraction, oil refining and oil filling. (Extract oil after dehulling can reduce the wax content of final oil.)

- What is the main equipment of sunflower oil manufacturing unit?

- Main Equipment: Cleaning/screening machine, seeds cooker, oil expeller, oil filter press and conveyors. This sunflower oil manufacturing unit is effective, automated and affordable which makes it ideal choice for small scale sunflower oil factory. It is capable of continuous cooking oil processing plant.

- What are the different types of sunflower oil processing machines?

- Packaging: The refined or filtered oil is then packaged for sale. - Small-Scale Machines: Can process 50 kg to 500 kg per hour of sunflower seeds, suitable for small farmers, home-based setups, or small-scale businesses. - Medium-Scale Machines: Can process 1 to 10 tons per day, suitable for medium-sized oil mills or commercial operations.

- What is the shelling process for small scale sunflower oil production line?

- For small scale sunflower oil production line with capacity less than 20T/D, the seeds can be expelled in oil press with shell. This process is very common in small scale oil extraction workshop or family oil milling business. Surely, the shelling process can be included for small scale production line if the customer request.