sunflower oil plant manufacturer in gwadar

- Usage: edible oil

- Type: Cold & Hot Pressing Machine, rajkumar oil expeller

- Production Capacity: 100%

- Voltage: 220V/380V

- Power(W): 7.5kw

- Dimension(L*W*H): 1950*1300*1900mm

- Weight: 950 kg

- Screw speed: 30-40 r/min

- gear ratio: 15/40x15/55=1

- Dimension: 1950*1300*1900mm

- Output: 150-250kg/h

- Power: Y160M-6-7.5KW

- Vacuum pump: Y90S-4-1.1KW

- Heater: 3KW

- Package: wooden case

- Quality: Top Level

Model Number: sunflower oil processing machine; Voltage: 230V-380V-430v or others; Power(W): ≤20kw/h; Dimension(L*W*H): according to capacity; Weight: according to the capacity; Certification: ISO9001; After-sales Service Provided: Engineers available to service machinery overseas; Product name: Sunflower oil machine price vegetable oil

Machine Type: sunflower oil making machine, Production Capacity: 8 to 10 Tons/Day, Dimension(L*W*H): Depend on cooking processing equipment capacity, Depend on the capacity, Voltage: 380/3/50, Specification: 15 m2, Core Components: Motor, Pump, Engine, Raw Material: sunflower, Market: gwadar

small sunflower oil processing plant setup in gwadar

- Usage: oil press machine

- Production Capacity: 50kg/h

- Voltage: 380V/50HZ/Triple phase

- Dimension(L*W*H): 1050*1100*1550mm

- Weight: 1250 KG

- Core Components: Pressure vessel

- Oil type: Sunflower Oil

- Product name: hydraulic oil press machine

- Function: Making Edible Oil

- Application: Oil Production Line

- Advantage: High Oil Yield

- Raw material: Sunflower cocoa butter

- Material: Carbon Steel Stainless Steel

- Color: Silver

- Item: Edible Oil Press

- Character: Professional Manufactuer

Product Using: Producing Sunflower Oil; Type: Sunflower Oil Processing Plant; Main Machinery: Sunflower Oil Processing Plant Machine; Automatic Grade: Automatic; Production Capacity: according to the specification of blackseed oil extraction machine; Model Number: according to specification of walnut oil extraction machine; Voltage: 220V/380V

Machine Type: sunflower oil processing plant, Production Capacity: 400 kg/h, Dimension(L*W*H): 297*85*194cm, Power: 7.5 or 11kw, Advantage: High Oil Yield cooking oil making machine, Core Components: other, Filter Press Polypropylene Filter Cloth, Raw Material: sunflower, Market: gwadar

Efficient Sunflower Oil Production Machines

- Type: Roasting Machine

- Application: Beans

- Voltage: 220V

- Appearance: Vertical

- Press Materials: Sunflower, Soyabeans, Sunflower, Grape Seeds

- Press Series: Second

- Customized: Customized

- Raw material: Sunflower

- Heating Method: Gas Electric

- Product Name: Seed Beans Roasting Machine

- Capacity: 4-7.5kg/Time

- Application1: Food Industry

- Function: Heating

- Transport Package1: Export Wooden Cases

- Function1: Roasting Sunflowers

- Item Name: Cooker

- Package: Wooden Case Package

- Breaking Rate (%): Less Than 1%

- Item: Fob

- After-Sales Service Provided: Online Support

- Transport Package: 1. Wooden Package 2. Container

- Specification: 97*48*107cm

- Production Capacity: 600sets/Month

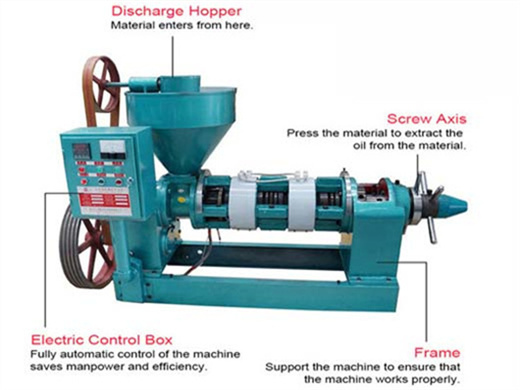

Key Components of a Sunflower Oil Making Machine: 1. Seed Cleaning System: Removes impurities (stones, dust, plant debris) from the sunflower seeds before the oil extraction process. Ensures better oil quality and a more efficient extraction process. 2. Seed Dehuller (optional): Removes the outer shells of sunflower seeds to increase the

The oil is extracted directly from the sunflower seeds by a screw type oil press machine. Sunflower seeds are cold-pressed (or hot pressed) at a certain temperatures, and the protein-rich cake that remains after the seeds are processed into oil is used as animal feed, retaining 99% of the nutrients in sunflower oil without the use of chemical solvents.

sunflower oil refined plant in gwadar

- Usage: Sunflower Oil

- Production Capacity: 100TPD

- Voltage: 230-380-430

- Power(W): 40kw/h

- Dimension(L*W*H): 1000m*800m*30m

- Weight: 100tons

- After-sales Service Provided: Overseas third-party support available

- Machinery type: Sunflower processing oil equipment

- Capacity: 5t/h-100t/h

- Residue in cake: less than 6%

- Sterilizer type: horizontal or vertical

- Vacuum degree: high vacuum

- Function: phsical oil press

- oil press type: screw oil press

- Power generation: back up turbine

- Oil color: red

- warranty period: 1year

sunflower oil refined plant in gwadar Machine Type: sunflower oil refinery machine; Production Capacity: 80-400kg/n; Weight (kg): 25, 25; Voltage: AC220

Oil processing equipments of oil mill plant

- Usage: Sunflower Oil, Cooking Oil

- Production Capacity: 1tpd

- Voltage: 220V/380V/440V

- Dimension(L*W*H): 1700*1100*1600mm

- Weight: 200 KG

- Core Components: Motor, Pressure vessel, Pump, Gear, Bearing, Engine, Gearbox

- Oil type: Sunflower Oil

- Dimension (mm): 2500x1600x2500

- Screw Speed (r/min): 28-40

- Certificate: ISO9001

- Color: Silver

- Production Power: 380V, 6 level, 18.5KW

- Capacity (kg/h): 400~600

- Raw Material: Sunflower

- Application: Screw Oil Expeller

Here in the oil milling plant, hot pressing means cooking the oil seeds with a hot pressing machine before pressing in order to extract more oil. All main parts of hot pressing machine such as the worm shaft, pressing worms, cage bars and gears are made of high-grade alloy steel that have undergone hardening treatment.

- What is sunflower oil & how to make sunflower oil?

- Sunflower seeds is a common oilseeds, in which there are 45-54% oil content. Sunflower oil, with golden color, clear and transparent, fragrance oil, is a kind of popular edible oil among people. How to make sunflower oil using sunflower oil production machine? There is the main process of sunflower oil production line.

- What are the steps of sunflower oil refining?

- The steps of sunflower oil refining mainly include degumming, decolorization, deodorization and dewaxing. The refined oil has light color, high nutritional value and good taste.

- What happens to sunflower oil after deodorization process?

- Dewaxing in the refining process: The sunflower oil after deodorization process also contains a small amount of wax, which is pumped into the pre-cooled crystallization tank and cooled at a certain cooling rate within 8 hours.