nigeria soybean oil production plants

- Usage: Soybean oil

- Type: Soybean Oil Press Machine

- Production Capacity: 50-500kg/h

- Voltage: 220V/380V/as your demand

- Dimension(L*W*H): 900*1000*1400mm

- Weight: 950 KG

- Core Components: Motor

- Oil type: Soybean Oil

- Raw material: Soybean

- Function: Oil Mill Making Pressing Extracting Machine

- Capacity: 50kg-1000kg/hour

- Feature: Multifunction High Efficient

- Processing Types: Hydraulic Pressing Cold Press

- Oil rate: Oil Yield 99%

- Power: 1.5kw

- Package: 900*1000*1400mm

- Material: Carbon Steel Stainless Steel

More than anything, the production of soybeans is destined for industrialization: 84% is used for the production of oil, flour and pellets. Export rights for soybeans, flours and oils. The soybean oil production plants belong to 31 companies, with an installed milling capacity of about 60 million tons per year (2018). Soybean oil

Explore the step-by-step process of extracting nutritious soybean oil from seeds, including crushing, solvent extraction, and mechanical pressing methods.

Improvement of Soybean Oil Solvent Extraction through

- Usage: Cooking Oil

- Production Capacity: 15~20 ton/day

- Dimension(L*W*H): 8.8*4.7*12.2 ft

- Weight: 0 KG

- Warranty: 1 Year against manufacturing defects

- Warranty of core components: Other

- Core Components: Other

- Oil type: Soybean Oil

- Application: Soybean oil Processing

- Raw material: Oilseeds

- Advantage: High Effieciency

hydrolysis as a pretreatment option to improve soybean oil solvent extraction and, on the basis of the results obtained, to de?ne a preparation stage adapted to existing industrial

Currently, industries adopt a continuous-countercurrent-multistage extractor extraction from vegetable oilseeds. In this configuration, at the last stage, the solid matrix, almost exhausted in oil (oil-poor), is put in contact with the pure (oil-free) solvent (hexane), whereas at the first stage, the new raw material is put in contact with the oil-rich extract, which has already gone

nigeria GLOBAL SKY BUSINESS

- Usage: Soybean Oil, Cooking Oil

- Type: Soybean Oil Press Machine

- Production Capacity: 30-60KG/H

- Voltage: 220V/110V/380V

- Dimension(L*W*H): 1200*780*1100MM

- Weight: 220 KG

- Core Components: Motor

- Oil type: Soybean Oil

- Product name: Soybean oil press

- Capacity: 30-60kg/h

- Raw material: Stainless Steel

- Bowl diameter: 55mm

- Screw speed: 52r/min

- Oil output rate: 10-30%

- Application: Soybean, Cactus seeds, Tomato seeds, Macadamias, Soybean fruit

- Working life: 20 years

- Package: Export wooden case

nigeria nigeria again the main supplier of soybean meal and oil worldwide nigeria was once again the main supplier of soybean meal and oil globally in 2021, exporting 26.6 and 5.4 million tons, respectively. According to data released by the US Department of Agriculture (USDA) and the Rosario Stock Exchange (BCR), nigeria ranks first in

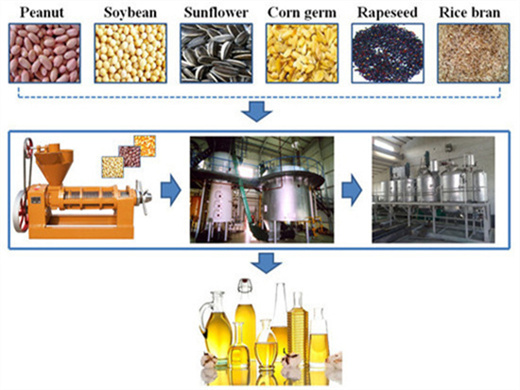

Soybean Oil Extraction Technology illustration. Usually, when the processing capacity of oilseeds is more than 20 tons/day, the extraction methods can be selected to produce soybean oil, which can reduce the production cost of soybean oil and obtain more profits. The Difference Between Soybean Oil Extraction Methods and Pressing Methods

Soybean Oil in nigeria The Observatory of Economic Complexity

- Usage: Soybean Oil

- Type: Soybean Oil Press Machine

- Production Capacity: 5~6 tons/day

- Dimension(L*W*H): 9.51*3.15*7.05 ft

- Weight: 0 KG

- Warranty: One year warranty against manufacture defect.

- Warranty of core components: Other

- Core Components: Other

- Oil type: Soybean Oil

Exports In 2022, nigeria exported $6.79B in Soybean Oil, making it the 1st largest exporter of Soybean Oil in the world. At the same year, Soybean Oil was the 3rd most exported product in nigeria. The main destination of Soybean Oil exports from nigeria are: India ($3.1B), Bangladesh ($513M), Peru ($404M), Morocco ($260M), and Chile ($244M).

Soybean Oil Processing Business Startup Cost and Project

- Usage: Soybean Oil

- Type: Rotocel extractor

- Color: based on requirements for oil solvent extraction machine

- Capacity: based on requirements for oil solvent extraction machine

- Use: use oil solvent extraction machine to make oil

- Oil grade: II

- Oil residue ratio: 1%

- Solvent: hexane

- Power consumption: ≤ 15KWh/T

- Steam consumption: ≤ 280KG/T (0.8MPa)

- Solvent consumption: ≤ 2Kg/T (No.6 solvent oil)

According to oil extraction methods, soybean oil production can be divided into mechanical oil pressing and solvent oil extraction. And crude soybean oil extracted from both mechanical or solvent has impurities and should be refined through a series of oil refining process to get edible refined soybean oil. Soybean Oil Processing Machines

- How is soybean oil extracted?

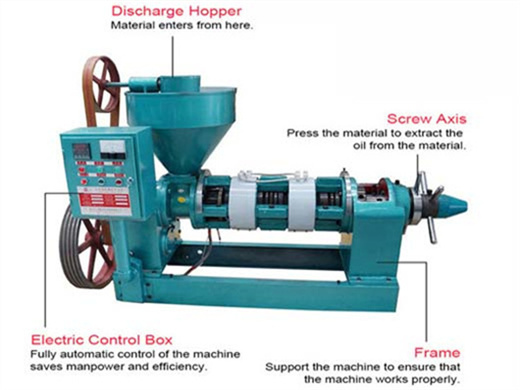

- Two common soybean oil production processes are solvent extraction (chemical) and mechanical extraction using a screw press. The most conventional method is to extract oil by mechanical oil processing machines. The oil obtained from screw press, known as crude oil, usually undergoes a filtration process before being consumed as food.

- What are the advantages of soybean extruder technology?

- Advantages of Extruder Technology: Soybean obtained after the preparatory process can be used as a raw material for Soybean Oil Extraction. The soybean contains 18 – 20 % oil content. After a single stage pressing, about 5 – 5.50% residual oil in the soybean meal which will be used in animal & poultry feed.

- Which countries produce soybean oil in the world?

- The major Soybean producing countries in the world are USA, Brazil, Argentina, China, India, Uruguay, Ukraine, Bolivia, Nigeria, South Africa Complete Turnkey 60 TPD Soybean Oil Mill Installed in Ethiopia Feel free to inquire for detailed information about soya bean oil extraction plant and soybean oil mill machinery.

- Why is automatic soybean oil processing plant necessary?

- Automatic soybean oil processing plant is necessary because of the low efficiency of the oil extracted by hand operated machines.

- How to set up a soybean oil mill plant?

- Here we have listed some of the basic machinery required to set up Soybean Oil Mill Plant Soybean oil extraction plant require a series of automated processing steps. Normally, the basic process of a soybean oil production plant is seed cleaning, destoning, oil pressing, Cake / Meal Conditioning, oil filtration.

- Why is soybean oil produced by a filter press machine?

- Therefore, the oil produced by the machine is Cold Press, Healthy and Free from any sort of toxins. The crude soybean oil contains suspended solids (foots) that need to be removed. The solids are removed by a filter press machine, as it has fine-mesh clothes which can separate liquids and solids using pressure.