moringa oil solvent extraction machine equipment in ghana

- Usage: Coconut cake oil extractor machine

- Type: oil extractor machine

- Production Capacity: 100kg/h, 500kg/h, 1tph, 5tph, 10tph

- Voltage: 380V/50HZ

- Power(W): According to capacity

- Dimension(L*W*H): 1200*400*900mm3

- Application: oil extracted

- Residual oil in meal: less than 1%

- Power consumption: not more than 15KWh/T

- Solvent consumption: less than 2kg/t

- Crude oil moisture and volatile matter: ≤ 0.30%

- Finished meal moisture: ≤ 13% (adjustable)

- Residual solvent in finished meal: ≤300PPM (qualified detonated experiment)

- Steam consumption: ≤ 280KG/T (0.8MPa)

The cold press method of moringa oil extraction requires electrical extraction machine while the solvent extraction method doesn’t. But there’s one easier way… check out Moringa oil price on Jiji and buy it cheaper from real sellers choose the best price! 6.1. Solvent extraction. This method works based on different solubility

International Journal of Engineering and Technical Research (IJETR) ISSN: 2321-0869, Volume-2, Issue-12, December 2014 Solvent Extraction and Characterization of Oil from Coconut Seed Using Alternative Solvents Okene E.O., Evbuomwan, B. O. Abstract— Solvent extraction and characterization of oil from coconut seed using alternative solvents have been studied.

Comparative Study of Coconut Oil Extraction Method

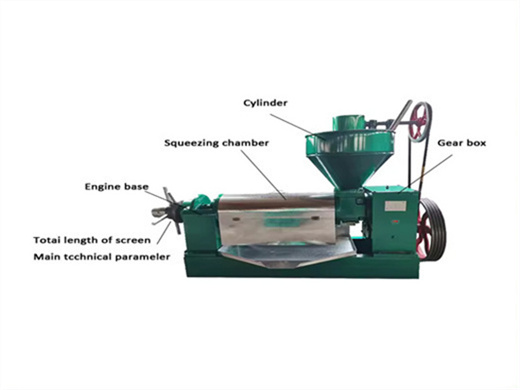

- Usage: Extract oil from plants

- Production Capacity: 9~11TPD

- Voltage: 380v/50hz

- Dimension(L*W*H): 2010*750*1430

- Weight: 825 KG

- Core Components: Gear, Bearing, Engine, Gearbox

- Oil type: Coconut Oil

- Easy to operate, low invest, compact.: Suit for squeeze Coconut,

- Coconut, shelled Coconut ,: Coconut, Coconut, etc.

- Customizable: Price negotiable

Discover the diverse techniques behind Coconut Oil Extraction Methods, from traditional approaches to modern innovations like cold pressing, hot extraction, and centrifugation. Unveil the quality and yield disparities between cold pressing and hot extraction, as well as the purity and efficiency advantages of centrifugation. Stay informed about the evolving methods that drive the multi-billion

The highest average oil yield of 82.7% (±3.03) was obtained from Chemical Extraction Method using n-hexane as solvent, Mechanical Extraction Method gave 72.9% (± 1.49) while the lowest oil yield

The Extraction, Purification, and the Recent Applications of

- Usage: Coconut Oil

- Type: equipment for the production crude Coconut oil

- Production Capacity: 10-3000TPD

- Voltage: 380v/440v or local voltage

- Power(W): According tothe equipment capacity everyday

- Dimension(L*W*H): 1200*400*900mm3

- Weight: According to the equipment capacity

- Raw material: Coconut, Copra

- Function: To make the Coconut oil

- Advantage: High Oilput

- Certificate: ISO 9001 Certificate

- Supplier: Manufacturer

- Automatic grade: Full automatic

- Item: Coconut Oil Machine

- Application range: Plant Seed

- Character: Oil Seeds Refining Line

Coconut oil can be extracted through wet extraction and dry extraction methods. Coconut oil refining is usually carried out on dry extracted coconut oil and generally includes the bleaching

Solvent extraction and characterization of oil from coconut seed using alternative solvents have been studied. The solvents used were Isopropanol and Petroleum ether. The Physicochemical parameters of the extracted oil was determined by standard methods of analysis. The percentage oil extracted were 94.7 and 72 for isopropanol and petroleum ether respectively. Also, the acid, peroxide (mg

Ultrasonic-assisted virgin coconut oil based extraction

- Usage: beans,Coconut,etc

- Type: cold pressing machine, Grain Processing Equipment

- Production Capacity: 20kg/h, 20kg/h

- Voltage: 220v, 220/110V

- Dimension(L*W*H): 72*41*70CM

- Weight: 65 kg

- Core Components: Motor

- Oil type: Coconut Oil

- Material: Stainless steel

- Packaging Details: 72*41*70CM

- Power: 2000W

- type: automatic cold and hot pressing

- Application: Edible Oil Production

- Color: Stainless Steel Color

- Quality: Top Level

The coconut oil also has high nutritive values and bioactivities with little or no adverse effect to human health (Krishna et al. 2010). Furthermore, the coconut oil based extract can be directly applied into numerous emulsion based foods and cosmetics without removal of solvent which are more convenient and cost effective to the industries.

Solvent assisted extraction of oil from Moringa oleifera Lam

- Usage: Cooking Oil

- Type: Oil Extraction Machine

- Production Capacity: 500-1000kg/24H

- Voltage: 220/380v, 380 v

- Dimension(L*W*H): 1850*1050*1750mm

- Weight: 240 KG

- Core Components: Motor, Engine

- Oil type: Coconut Oil

- Motor Power: 3kw

- Capacity: 500-1000kg/24H

- Model: 6YT-60B

- Application: cocoa butter hydraulic oil press

- usage: mini hydraulic oil press

- Product name: Coconut oil pressers

- System Pressure: 60 mpa

The solvent extraction technique is the oldest technique used for the extraction of the oil. The solvent extraction technique has the ability to perform the extractions on a liquid or a solid sample with the minimal effort. Solvent extraction using chloroform:methanol (C:M (1:1)) has been reported by (Lalas and Tsaknis, 2002). In the present

- How to extract coconut oil?

- Three diferent extraction techniques were used to extract coconut oil. Induced cold press, soxhlet, and supercritical fluid extraction (SFE). All extractions were conducted in triplicates and averages of the results were used. In the pressing process performed with the cold press device (GM-1000), small diameter 10 mm apparatus was used.

- How to extract oil from coconut copra?

- A previous study indicated that 100% of oil could be extracted from the coconut copra within 1 h by using supercritical carbon dioxide (SC-CO 2) as the extraction solvent with the condition of 120°C and 517 bar.

- What is the process of coconut extraction using cold extraction techniques?

- Overall process of coconut extraction using cold extraction techniques Hot extraction process is an extraction process that involves heat. This heating step however will reduce the antioxidant properties of the coconut oil produced . Hot extraction process is a process in which heat is used to break the emulsion between water and oil molecules.

- What is virgin coconut oil?

- Virgin coconut oil is a new highly value added version of coconut oil in health food markets. Extraction of virgin coconut oil from coconut kernel is a major influential step for their commercialization. There are many extraction methods, among which cold and hot extraction are conventional extraction processes.

- Why is SFE extraction the best way to obtain coconut oil?

- Compliance with these standards is an indi-cator of the quality of the oil. Its shelf life is long, low degradability, and low rancidity. As a result, SFE extraction is the best method to obtain coconut oil in terms of yield, fatty acid content, and health.

- Which is the best method to obtain coconut oil?

- As a result, “green extraction” SFE is the best method to obtain coconut oil in terms of yield, fatty acid content, and health. Coconut (Cocos nucifera Linn.), which member of the family of Arecaceae (Palmae), is an important organ of the monocotyledons, grown along the tropic and sub- tropic areas.