Soybean oil production process in a edible oil plant

- Usage: Cooking Oil

- Type: Seed Roaster

- Production Capacity: 120kgs/h

- Voltage: 220/380V

- Dimension(L*W*H): 1400*860*1260mm

- Weight: 275

- Application: oil press machine uk

- Function: Oil Pressing

- Capacity: 120kgs/h

- Feature: High efficiency and automatic

- Machine Material: Carbon steel and stainless steel

- Quality: High Level

Explore the step-by-step process of extracting nutritious soybean oil from seeds, including crushing, solvent extraction, and mechanical pressing methods.

Soybean seed oil extraction process in Zambia,Doing Group is serving Zambia customers for soybean seed oil extraction process plant, this oil extraction plant can process 30,000 to 34,500 ton of soybean seeds every year, this plant is adopted (N-hexane) solvent extraction tech.

Soybean Oil Extraction and Processing Springer

- Usage: Soybean Oil

- Automatic Grade: Semi-Automatic

- Production Capacity: 100%

- Voltage: 220V

- Power(W): 5.5kw

- Dimension(L*W*H): 46*32*36cm

- Weight: 130kg

- Product name: Hydraulic oilve oil press machine for sale

- Item: Vertical Oil Press

- Advantage: Energy Saving

- Warranty: One Year

- Function: Hot Press

- Feature: Multifunction

- Product: Oil Reach

- Quality: Efficient

- Application: Soybean Oil Expeller

- Use for: Soybean

ary aspiration. However, fines are included with the meats extraction to maximize extraction yield, even though they may create solvent filtration prob? lems during oil extraction. The soy cotyledon contains about 20% oil, whereas the hull has negligible oil content. Hulls are often removed to separate the oil-bearing cotyledons. However,

Solvent extraction process To remove any soybeans oil which remains during extrusion process highly volatile hydrocarbon is used. This solvent normally hexane absorbs any oil remaining in the seeds. Later the oil is acquired when the solvent evaporates due to its volatile nature. Refining the extracted oil

Soybean oil extraction with ethanol from multiple-batch

- Usage: Soybean oil, Soybean

- Type: Oil Extraction Machine, Cold & Hot Pressing Machine, Cold and hot press

- Production Capacity: 1t/day-1t/hour-100%

- Voltage: 180-240V/50-60Hz

- Dimension(L*W*H): 70*45*65 CM

- Weight: 74kg

- Feature: Full automatic, cold press with oil filter

- Input Capacity: 20kg raw material per hour

- Material: Stainless steel body,chamber and screw

- Working life: 6-8 years

- Advantage: Easy use,energy saving,simple operation

- Color: Silver

- Keep working: 12 hours

Currently, industries adopt a continuous-countercurrent-multistage extractor extraction from vegetable oilseeds. In this configuration, at the last stage, the solid matrix, almost exhausted in oil (oil-poor), is put in contact with the pure (oil-free) solvent (hexane), whereas at the first stage, the new raw material is put in contact with the oil-rich extract, which has already gone

The solvent extraction of soybean oil uses a solvent like hexane to dissolve the oil molecules from the raw material. Desired soybean oil. [email protected] 0086-159-3728-9608 0086-159-3728-9608

9.11.1 Vegetable Oil Processing U.S. Environmental

- Usage: cold press oil extraction machine

- Type: Soybean Oil Press Machine

- Production Capacity: 5TPD-100TPD

- Voltage: 220V/50HZ triphase

- Dimension(L*W*H): 1055*805*345mm

- Weight: 27.1 KG

- Warranty: 1 Year, 1year

- Core Components: Motor, Engine

- Oil type: Soybean Oil

- Advantage: High Oilput

- Character: Easy Movable

- Function: Oil Pressing

- Color: Customer Required

- Quality: High Level

- Operation: Easily

- Model: TS-BXG-128

Solvent Extraction and Oil Desolventizing The extraction process consists of "washing" the oil from the soybean flakes with hexane solvent in a countercurrent extractor. Then the solvent is evaporated (i. e., desolventized) from both the solvent/oil mixture (micella) and the solvent-laden, defatted flakes (see Figure 9.11.1-3). The oil is

Solvent Extraction AOCS

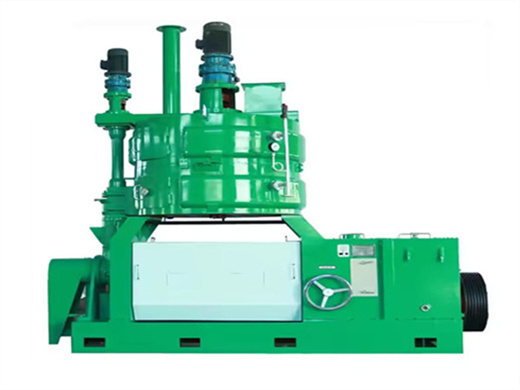

- Usage: Prices Oil Seed Extracting Machinery In Pak

- Production Capacity: 98%-100%

- Voltage: 380

- Power(W): 5.5KW~15KW

- Dimension(L*W*H): 2200*1600*2150

- Weight: 780kg

- Capacity of cold pressed Soybean oil: 35kg-400kg/h

- Material of cold pressed Soybean oil: Stainless Steel SS304/316

- Residual oil rate: 5~7%

- Raw material: Soybean

- Warranty period: 12 months

- Application range: Oil Production Line

- Feature of cold pressed Soybean oil: High Oil Yield Efficiency

- Function of cold pressed Soybean oil: Produce High

- Character: Plant Oil Press

Figure 3 is a simplified layout of an extraction plant. Figure 3. Solvent extraction distance diagram. Reference NFPA-36, (2009 simplified). The Solvent Extractor. Percolation Extractor: At the center of the extraction plant is the extractor. A percolation-type extractor is by far the most commonly used for the removal of oil from oilseeds

- What is soybean solvent extraction?

- Soybean Solvent Extraction = The solvent extraction process is where the extraction of desirable compounds from soybeans occurs, and can be completed in approximately four steps: Extraction — Hexane is used to produce two kinds of products: a wet meal with the solvent and a mixed oil that contains the solvent and soybean oil.

- How is soybean oil extracted?

- Two common soybean oil production processes are solvent extraction (chemical) and mechanical extraction using a screw press. The most conventional method is to extract oil by mechanical oil processing machines. The oil obtained from screw press, known as crude oil, usually undergoes a filtration process before being consumed as food.

- Which countries produce soybean oil in the world?

- The major Soybean producing countries in the world are USA, Brazil, Argentina, China, India, Uruguay, Ukraine, Bolivia, Nigeria, South Africa Complete Turnkey 60 TPD Soybean Oil Mill Installed in Ethiopia Feel free to inquire for detailed information about soya bean oil extraction plant and soybean oil mill machinery.

- What are the basic processes of soybean oil production plant?

- Normally, the basic process of a soybean oil production plant is seed cleaning, destoning, oil pressing, Cake / Meal Conditioning, oil filtration. Every process has the respective soybean oil processing equipment to fulfill its functions. Seed cleaner is used to remove the big and small impurities such as iron, stones, clump, dust, plant leaf, etc.

- What are the advantages of soybean extruder technology?

- Advantages of Extruder Technology: Soybean obtained after the preparatory process can be used as a raw material for Soybean Oil Extraction. The soybean contains 18 – 20 % oil content. After a single stage pressing, about 5 – 5.50% residual oil in the soybean meal which will be used in animal & poultry feed.

- How to set up a soybean oil mill plant?

- Here we have listed some of the basic machinery required to set up Soybean Oil Mill Plant Soybean oil extraction plant require a series of automated processing steps. Normally, the basic process of a soybean oil production plant is seed cleaning, destoning, oil pressing, Cake / Meal Conditioning, oil filtration.