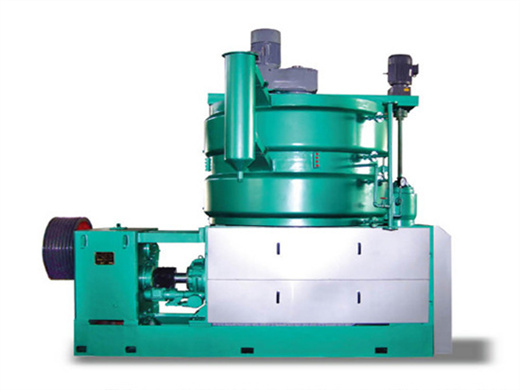

Copra/Coconut Oil Milling Process Offered by Oil Mill Plant

- Usage: Coconut Oil

- Production Capacity: 20~2000T/D

- Voltage: 380v/50Hz

- Power(W): up to specification

- Dimension(L*W*H): 1360*950*1170mm

- Weight: up to specification

- Function: Coconut bean oil expeller

- Capacity Model: 10T/H,30T/H,45T/H,60T/H,80T/H,100T/H

- Suitable material: Coconut and such oil material

- Patent product: Yes

- Patent No.: ZL2007 20092291.7;

- Fully automatic: Yes

- Technology support: life time

- Warrenty: one year

- After-sale service: Offering installation and debugging

Coconut Oil Milling Process. Coconut oil milling process or technologies are classified into two major types: the dry and the wet processes. The coconut oil processing starts with copra as the raw material is termed as the dry process, while the method that uses fresh coconuts as starting material is generally called the wet process.

Handcraft Blends Fractionated Coconut Oil 100% Pure & Natural Premium Grade Coconut Carrier Oil for Essential Oils, Massage Oil, Moisturizing Hair Oil & Body Oil 16 fl. Oz In the next section, we will delve into the process of preparing the coconut oil for fractionation.

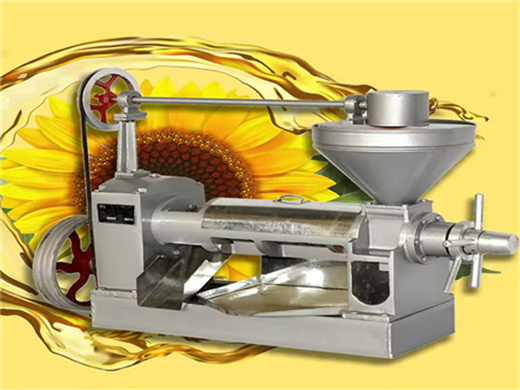

Refined Coconut Oil and Detailed Refing Process Oil Mill Plant

- Usage: Coconut Oil

- Type: Coconut Oil Press Machine

- Production Capacity: 50-700kg/h

- Voltage: 220V

- Dimension(L*W*H): 480*160*360mm

- Weight: 13 KG

- Core Components: Motor

- Oil type: Coconut Oil

- Product name: Oil Press Machine

- Application: Squeeze Oil

- Mode: full Automatic Oil Presser

- Material: Stainess Steel

- Feature: High Oil Yield Efficiency

- Temperature adjustable: 50°, 120°, 180°, 200°, 220°

- MOQ: 1 set

Refined coconut oil also known as the RBD Coconut Oil, which refers to the oil that has been refined, bleached, and deodorized. The oil is derived from dried copra known as copra. Actually, the oil that is expelled directly from copr

This research was aimed to conduct solvent-free crystallization and fractionation of virgin coconut oil (VCO). This study investigated the effect of surface contact area-to-volume ratio and mixing conditions on crystal characteristics.

coconut Oil Fractionation Dry Fractionation Process

- Usage: cooking oil making equipment, cooking oil making equipment

- Type: cooking oil making equipment

- Voltage: according your requirement

- Power(W): according the capacity of cooking oil making equipment

- Dimension(L*W*H): according the capacity of cooking oil making equipment

- Weight: according the capacity of cooking oil making equipment

- solvent: residual oil in cake: 1%

- extractor type: rotocel extractor

- Solvent consumption: ≤ 3Kg/T (6 #solvent oil)

- Crude oil moisture and volatile matter: ≤ 0.30%

- Power consumption: ≤ 15KWh/T

- steam consumption: ≤ 280Kg/T (0.8MPa)

- Finished meal moisture: ≤ 10-13% (adjustable)

- Residual solvent in finished meal: ≤ 300PPM (qualified detonated experiment)

What Is the Process of Fractionation of coconut Oil? Heating. coconut oil is semi-solid at room temperature, and its fatty acid composition is about half saturated acid (120, 140, 160.180, 200) and half unsaturated acid (161, 181182, 183).

Fractionated coconut oil and MCT oil production: facts and fiction * French Oil Mill Machinery Co. Process Plus, LLC, Cincinna, Ohio, USA

Process Design of an Integrated Virgin Coconut Oil (VCO

- Usage: Coconut Oil

- Automatic Grade: Semi-Automatic

- Production Capacity: 100%

- Voltage: 220V

- Power(W): 5.5kw

- Dimension(L*W*H): 46*32*36cm

- Weight: 130kg

- Product name: Cocoa hydraulic press machine for sale

- Item: Vertical Oil Press

- Advantage: Energy Saving

- Warranty: One Year

- Function: Hot Press

- Feature: Multifunction

- Product: Oil Reach

- Section: Pre Pressing Section

- Application: Oil Production Line

- Material: Stainless Steel 304

Process Design of an Integrated Virgin Coconut Oil (VCO 5 &, $& $ ))$

Small Coconut Oil Extraction Production Machine Starts

- Usage: for different kinds of crude oil

- Type: For oil refinery for sale in united states usage

- Production Capacity: 100-500 ton

- Voltage: 380V 440V

- Power(W): As Coconut oil refining process output every day

- Dimension(L*W*H): Depend on Coconut oil refining process capacity

- Weight: As per Coconut oil refining process output

- Item: Coconut oil refining process

- Material: Stainless steel

- Refining process: Degumming , Bleaching , Deodorizatizing

- Grades of refined Coconut oil: one grade ,two grade ,three grade ,

- Temperature of deodorization: 280degree

- Consumption of white clay: 1-3%

- Phosphoric acid: 0.2-0.3%

- Soften water: 150kg /ton

- Alkali consumption: 0.8-1.5kg /ton crude oil

- Circulating water: 1-2cm3 /ton crude oil

Mechanical Coconut Oil Extraction Process: the dry coconut with 10% ~ 12% moisture is transported to the automatic scale to remove the broken iron through the magnetic chamber, and is ground into particles of about 0.3 cm in diameter, and the particles are pressed into a thin sheet to enlarge the surface of the dried coconut oil extracting.

- What are the different types of coconut oil milling process?

- Coconut oil milling process or technologies are classified into two major types: the dry and the wet processes. The coconut oil processing starts with copra as the raw material is termed as the dry process, while the method that uses fresh coconuts as starting material is generally called the wet process.

- How is coconut oil processed?

- The coconut oil processing starts with copra as the raw material is termed as the dry process, while the method that uses fresh coconuts as starting material is generally called the wet process. Dry processing of meat for coconut oil milling process involves the conversion of coconut meat into copra prior to expelling and refining.

- What is the dry processing of meat for coconut oil milling process?

- Dry processing of meat for coconut oil milling process involves the conversion of coconut meat into copra prior to expelling and refining. This process is however done off-farm, in an oil mill. At the mill, the copra undergoes the following steps:

- How is coconut oil extracted from copra?

- The copra is pressed or dissolved with solvents, producing the coconut oil and a high-protein, high-fiber mash. The mash is of poor quality for human consumption and is instead fed to ruminants; there is no process to extract protein from the mash. A portion of the oil extracted from copra is lost to the process of extraction.

- How much coconut oil can be extracted from coconut milk?

- Coconut oil can also be extracted from the dry residue left over from the production of coconut milk. A thousand of mature coconuts weighing approximately 1,440 kilograms (3,170 lb) yield around 170 kilograms (370 lb) of copra from which around 70 litres (15 imp gal) of coconut oil can be extracted.

- What is coconut oil?

- Coconut oil is an edible oil extracted from the kernel or meat of matured coconuts harvested from the coconut palm (Cocos nucifera). It has various applications in food, medicine, and industry. Because of its high saturated fat content it is slow to oxidize and, thus, resistant to rancidification, lasting up to two years without spoiling.